MEPNew2Brew

Well-Known Member

- Joined

- Jan 26, 2013

- Messages

- 311

- Reaction score

- 26

Does the length of the mash affect fermentability, assuming the mash temperature is held constant through the entire mash? If so, why?

Does the length of the mash affect fermentability, assuming the mash temperature is held constant through the entire mash? If so, why?

Does the length of the mash affect fermentability, assuming the mash temperature is held constant through the entire mash? If so, why?

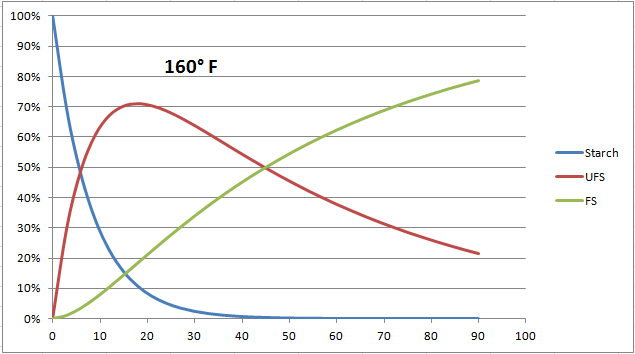

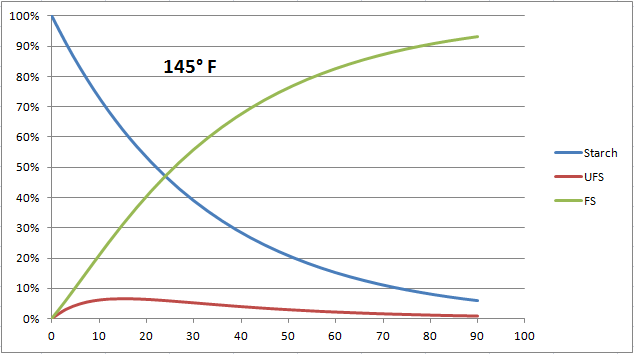

Yes, mash time does effect fermentability. You will convert starches to sugar relatively quickly but after that you will continue to convert non-fermentable sugar to fermentable sugars as they are further broken down. Example: at a 150 degree mash at the 30 min mark you will have about 8%ish starches left, 42% unfermentable sugar, and about 50% fermentable sugar. After 60 minutes your starches will be close to 0%, UFS at 16%, and FS at about 84%.

http://www.woodlandbrew.com/2013/01/mash-temperature-theory.html

It is from the charts found on this page (hopefully the picture loads correctly)

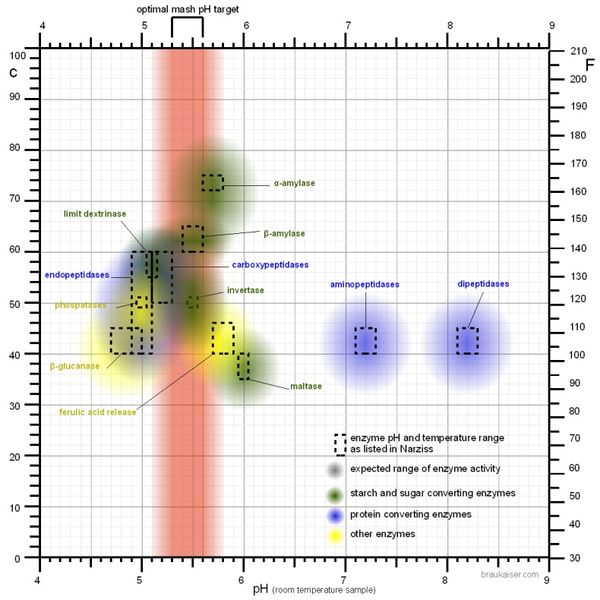

And this does make sense to me since at most mash temps there are both alpha and beta amalyse active so if you are producing unfermentable sugar at higher temps that those unfermentable sugars can be broken down further into fermentable sugars.

Thanks for sharing that graph.

I don't interpret it the same way as you are. I don't agree with your interpretation.

Yes fermentability is increasing over the course of the mash but that is because the sugar content is increasing as the starch content is reducing. You can't use this to control fermentability except by not achieving full starch conversion.

At the earlier phase in the mash duration, unfermentable sugars are present in greater proportion yes. These longer sugars are not reducing in quantity but are only reducing as a percentage of the total sugar content as more and more starches are converted to maltose.

The other two graphs in the article however show the full picture where mash temperature is the key player, not mash time. The link you shared does not support your position.

With this interpretation, the 160 degree temp chart. At 30 minutes the total starch is about 3%ish meaning that the total sugar content (FS + UFS) is about 97%. Over the next 30 minutes it shows the starches decreasing to roughly 0%, a difference of about 3%, but it shows the UFS and FS changing significantly more that 3%. So that says that the UFS is being broken down into FS.

I agree with you there but would argue the graph is in error, not the science. Specifically the point of intersection of the red and green on the y axis and the starch curve leveling off too early. These are only models after all and not actual measurements taken on specific mashes. They should not be interpreted with the level of exactitude you are using IMO.

The other interpretation is that the dextrin is being converted to maltose by the action of alpha amylase. Not something I am familiar with but concede I have much to learn on this specific topic.

Fair point. I need to start brewing enough to be able to actually do this type of experiment.

Enter your email address to join: