BandonBrewingCo

Well-Known Member

Hi,

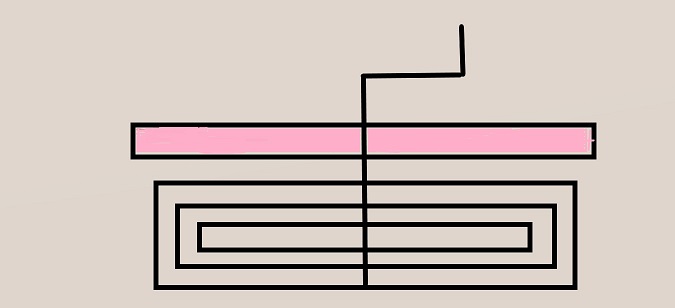

I've got a 15G SS Brewtech kettle with false bottom on an induction heater. I've got a 12V pump recircing the mash but it seems to be murdering my conversion effeciency.

So i gave the grain bed a poke and it is very, very compact. Not at all compact enough to stop flow mind you, I'm just worries that some grains arent having enough contact with the water and therefor not releasing all their goodness.

Can I somehow restrict the flow of the dc pump by using ball valves? Or will that mess up the pump?

Thanks in advance

I've got a 15G SS Brewtech kettle with false bottom on an induction heater. I've got a 12V pump recircing the mash but it seems to be murdering my conversion effeciency.

So i gave the grain bed a poke and it is very, very compact. Not at all compact enough to stop flow mind you, I'm just worries that some grains arent having enough contact with the water and therefor not releasing all their goodness.

Can I somehow restrict the flow of the dc pump by using ball valves? Or will that mess up the pump?

Thanks in advance

Last edited: