I use Brewfather online for my recipes and it gives me a guess at OG and FG. For whatever reason I haven't determined yet, I'm always a 2-4 points low. ....But this last beer I did I was 16 points low! Just wanted to get some opinions on why my mash efficiency was so off.

To me the most obvious would be a bad grain crush. I have it done at a local brew shop and is one of the few things I'm not doing myself yet.

But I also noted during the brew session that I had a low pH (as measured 10 minutes into the mash). I usually shoot for 5.4 - 5.6 measured at room temperature. It was actually a pH of 5.3 at room temperature. Could that low pH affect mash efficiency?

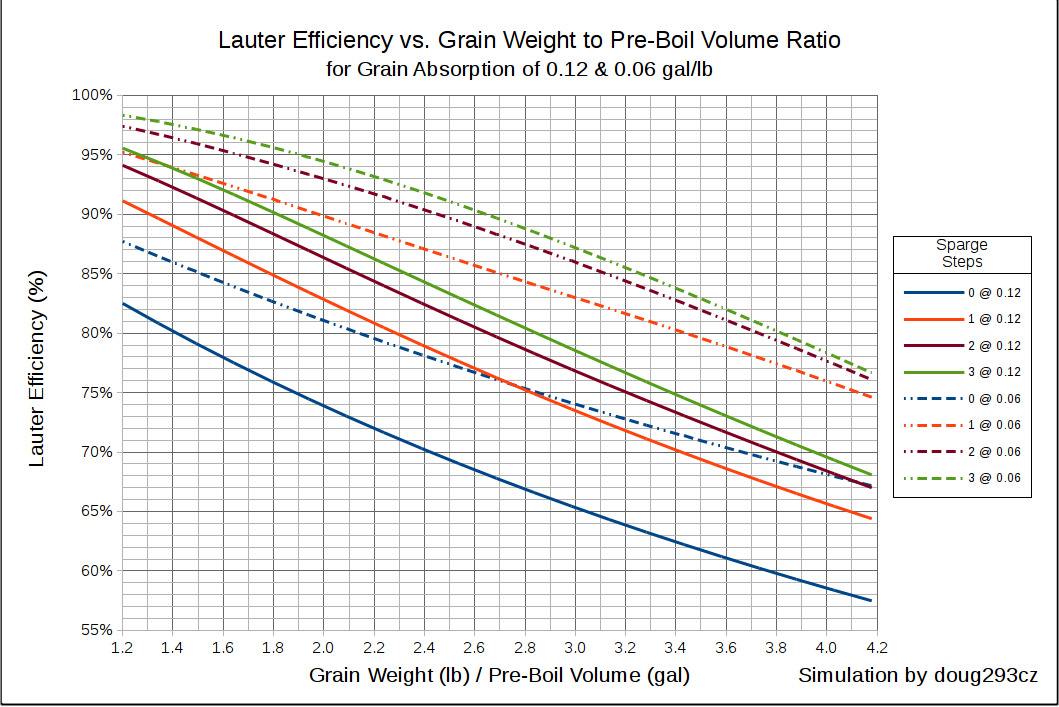

One other thing, I sparged at a much slower rate than I had before on my 3 kettle system. There was some discussion in another thread that suggested if you sparge TOO SLOW, it will actually have a negative consequence as far as extracting all the sugars.

Thanks for any input/thoughts/experience!

To me the most obvious would be a bad grain crush. I have it done at a local brew shop and is one of the few things I'm not doing myself yet.

But I also noted during the brew session that I had a low pH (as measured 10 minutes into the mash). I usually shoot for 5.4 - 5.6 measured at room temperature. It was actually a pH of 5.3 at room temperature. Could that low pH affect mash efficiency?

One other thing, I sparged at a much slower rate than I had before on my 3 kettle system. There was some discussion in another thread that suggested if you sparge TOO SLOW, it will actually have a negative consequence as far as extracting all the sugars.

Thanks for any input/thoughts/experience!