augiedoggy

Well-Known Member

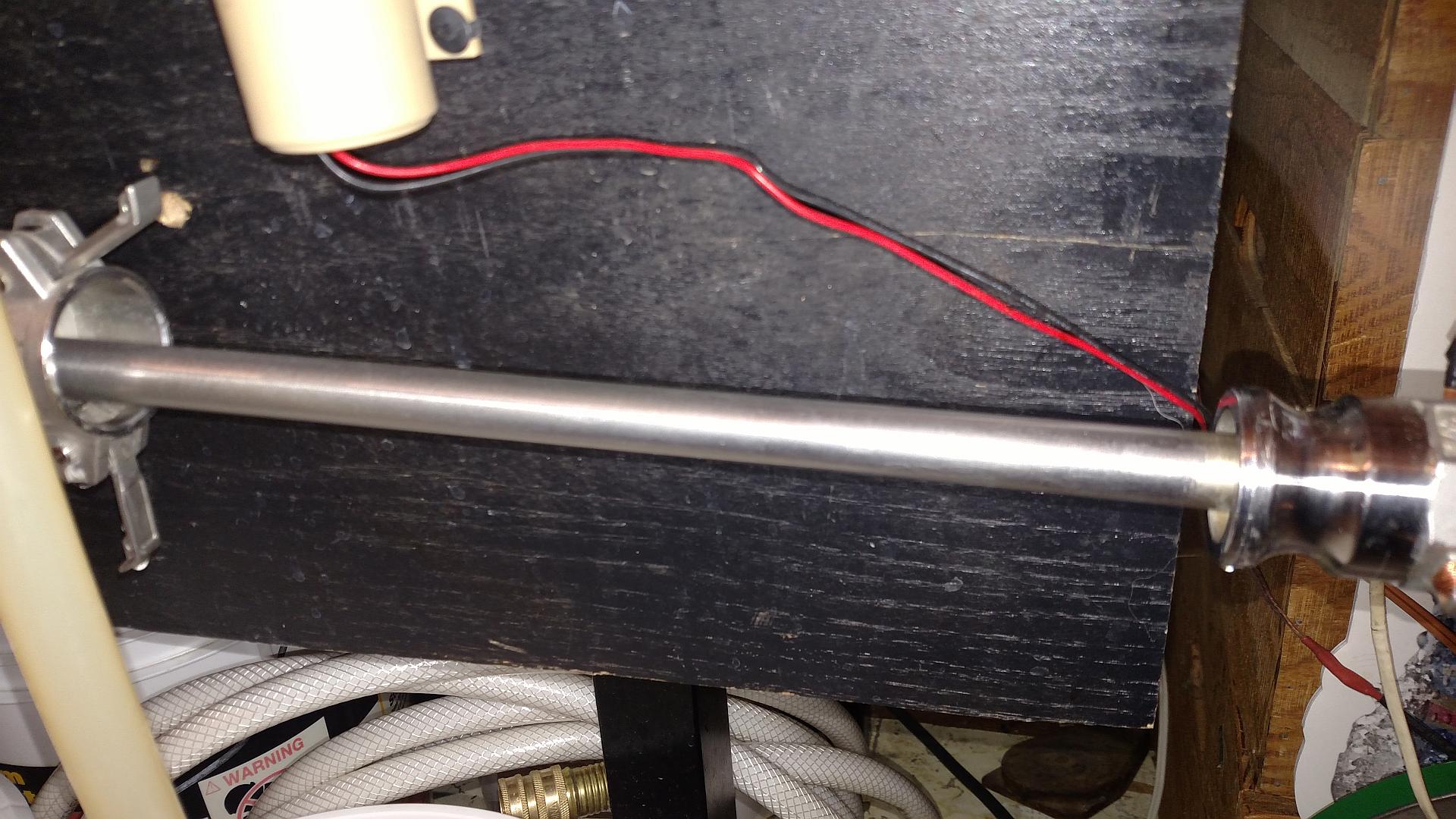

this is what I used on my latest rims... two of these with two compression fitting mounted inside with elements in them. its for my 3bbl rims though.. I believe all the 3/4" compression fittings require 3/4" npt threads.Do you know if they have one for a 3/4 diameter cartridge heater?

https://www.brewhardware.com/product_p/tc15f12nptdouble.htm

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)