Need input.

I'm getting ready to build one--but I need to have it so it doesn't trake up a lot of room, and it needs to be fairly inexpensive to build (less than 200 bucks, for sure. I've got XtrmXJ welding it so I'm good there. Just need inputs on the design. This thing has to grow with me, so it has to be functional at first to only utilize 1 pump, and most importanlt not take up too much space and be portable.

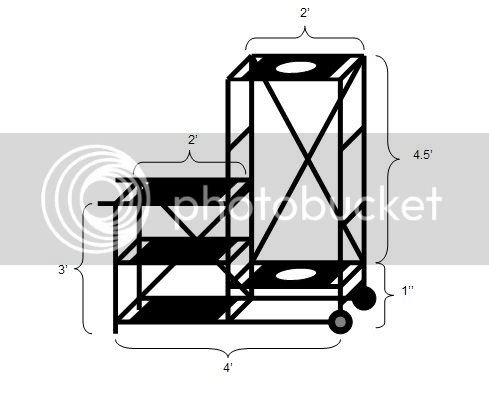

Here is my rough design--PLEASE critique, add suggestions.

Top tier holds the HLT, bottom right tier holds the boil pot, middle left tier holds the mashtun. Shelf below that I will mount the pump and a plate chiller (I'm gettin' a Shirron, dudes!!!!!)

I'm getting ready to build one--but I need to have it so it doesn't trake up a lot of room, and it needs to be fairly inexpensive to build (less than 200 bucks, for sure. I've got XtrmXJ welding it so I'm good there. Just need inputs on the design. This thing has to grow with me, so it has to be functional at first to only utilize 1 pump, and most importanlt not take up too much space and be portable.

Here is my rough design--PLEASE critique, add suggestions.

Top tier holds the HLT, bottom right tier holds the boil pot, middle left tier holds the mashtun. Shelf below that I will mount the pump and a plate chiller (I'm gettin' a Shirron, dudes!!!!!)