So we did our first water test on the BK and HLT for our new E HERMS last night. Everything was good with the exception of both element enclosures.

We are using two of http://www.brewhardware.com/product_p/hotpod-ewl.htm these weldless enclosures from @Bobby_M. The nuts are from Amazon.

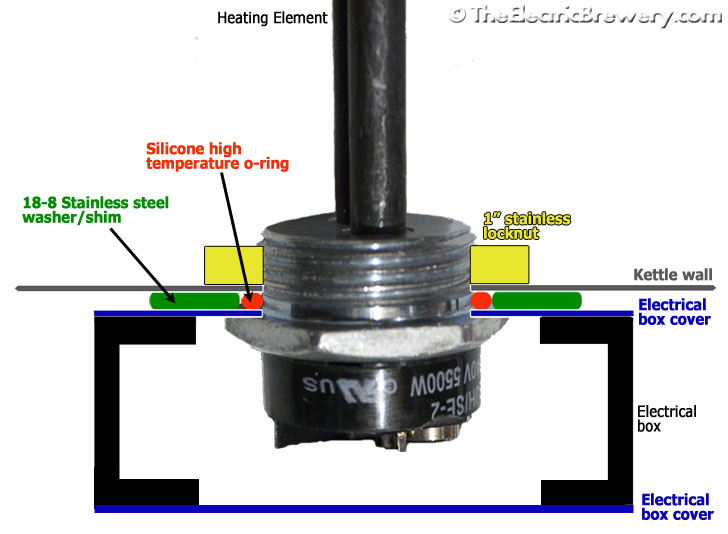

We have the o-ring on the inside of the kettles but cannot get them to seal properly. They are installed in Bayou Classic 82qt SS pots.

Do we just need to keep working to get them tighter? A buddy suggested moving the o-ring to the outside, but I wan to make sure the kettles are properly connected to ground and was thinking having the o-ring on the outside would break the connection to the ground in the element enclosure.

View attachment ImageUploadedByHome Brew1429803618.596158.jpgView attachment ImageUploadedByHome Brew1429803634.179685.jpgView attachment ImageUploadedByHome Brew1429803649.963840.jpgView attachment ImageUploadedByHome Brew1429803673.579584.jpg

We are using two of http://www.brewhardware.com/product_p/hotpod-ewl.htm these weldless enclosures from @Bobby_M. The nuts are from Amazon.

We have the o-ring on the inside of the kettles but cannot get them to seal properly. They are installed in Bayou Classic 82qt SS pots.

Do we just need to keep working to get them tighter? A buddy suggested moving the o-ring to the outside, but I wan to make sure the kettles are properly connected to ground and was thinking having the o-ring on the outside would break the connection to the ground in the element enclosure.

View attachment ImageUploadedByHome Brew1429803618.596158.jpgView attachment ImageUploadedByHome Brew1429803634.179685.jpgView attachment ImageUploadedByHome Brew1429803649.963840.jpgView attachment ImageUploadedByHome Brew1429803673.579584.jpg