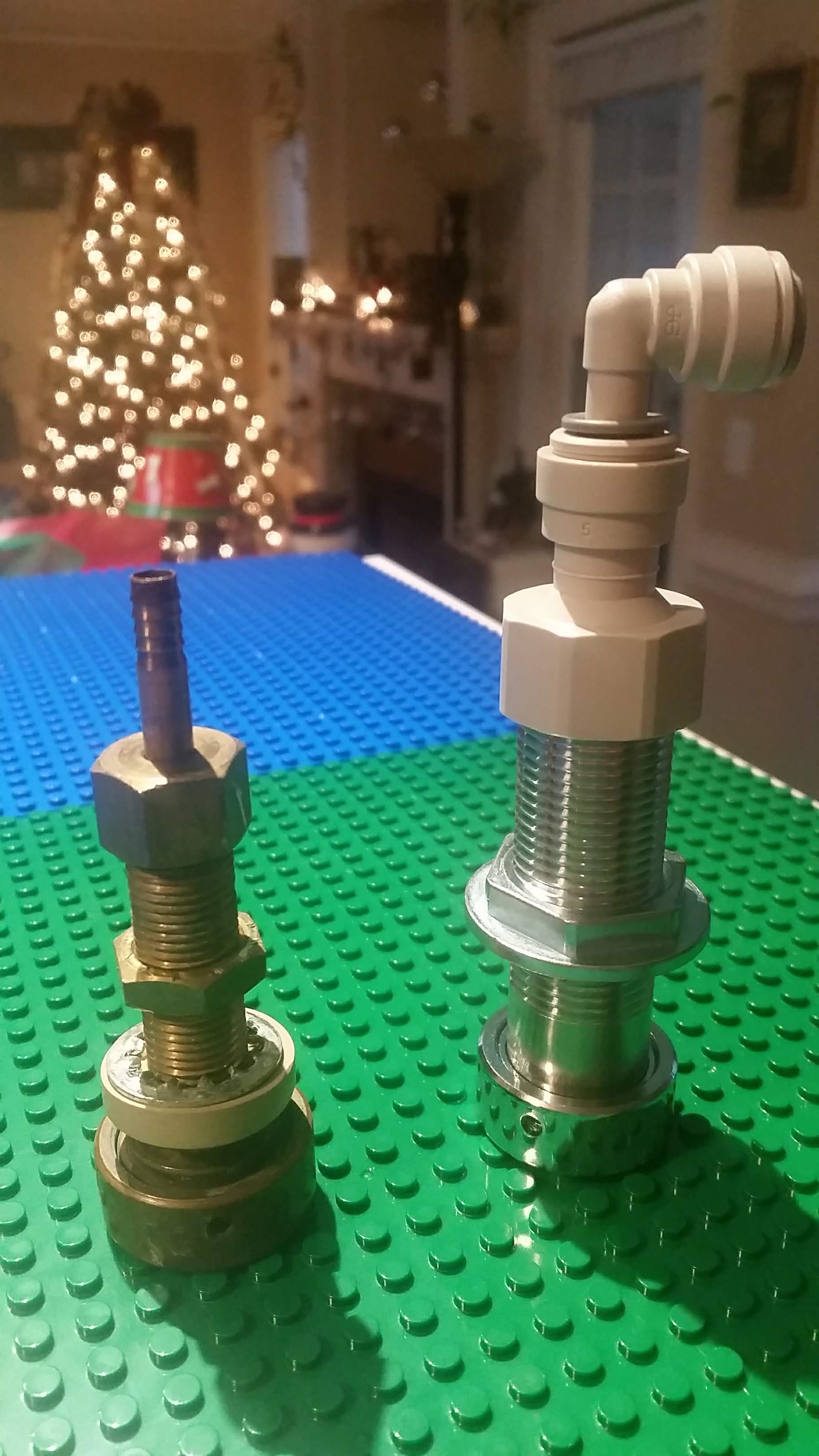

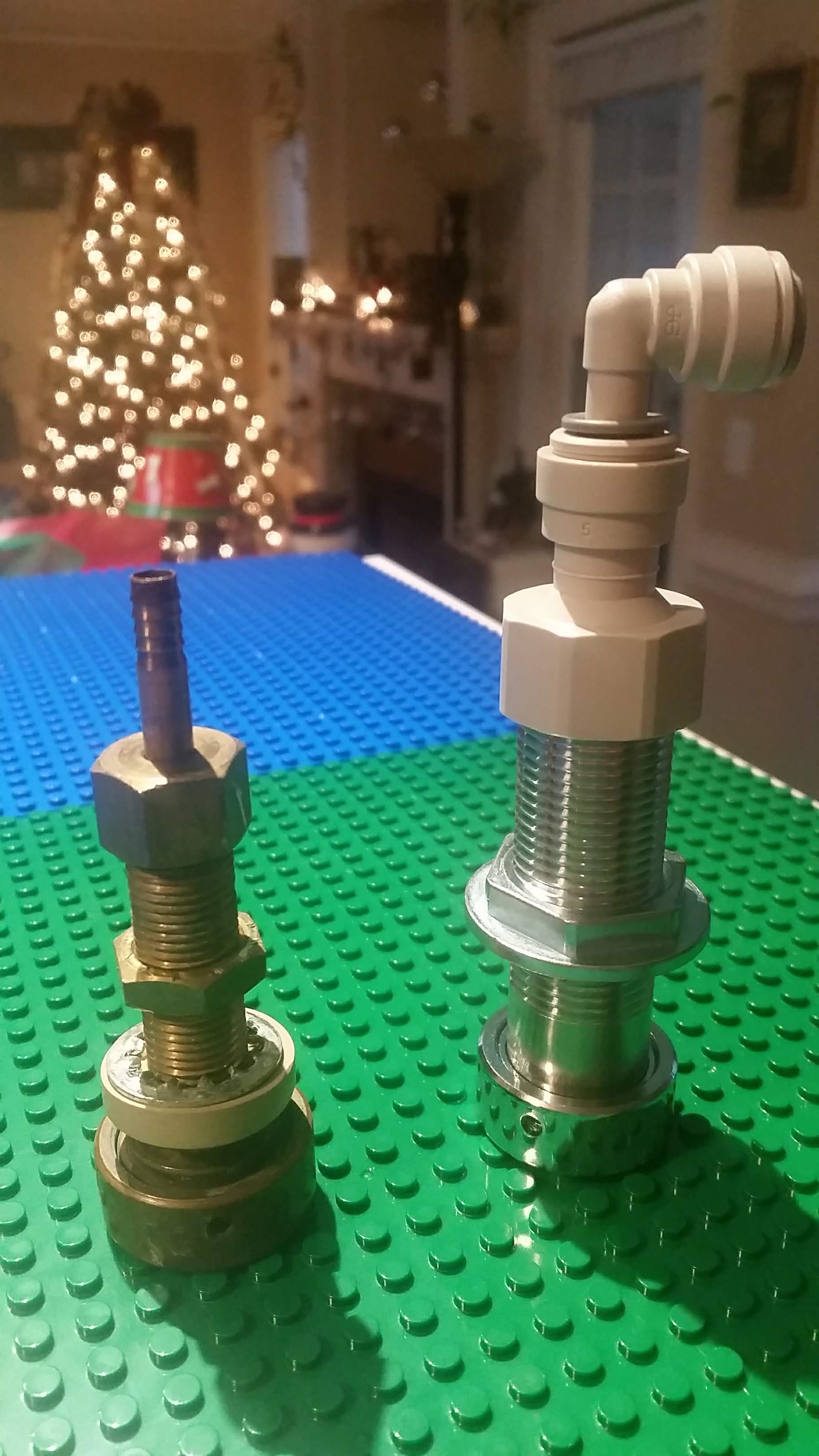

So I decided to rebuild the first kegerator I ever built. The shanks in it were brass and looking pretty nasty. After removing the first shanks, it dawned on me that these were not the standard shanks being used today. Not sure how old these originals are.

Ordered up two 2-1/8" and two 3-1/8" stainless shanks (just kind of guessing at what size I would need). After receiving them and eyeballing the space I had to install them, I knew it was going to be tight. I went ahead and drilled out one of the shank holes and fitted the new shank. Still looked sketchy, but had now committed myself by drilling out that first hole. Not sure whether it was going to work, I went ahead a shopped out a standard 4-tap tower just in case. I really didn't want to spend another $250, but knew I might have to.

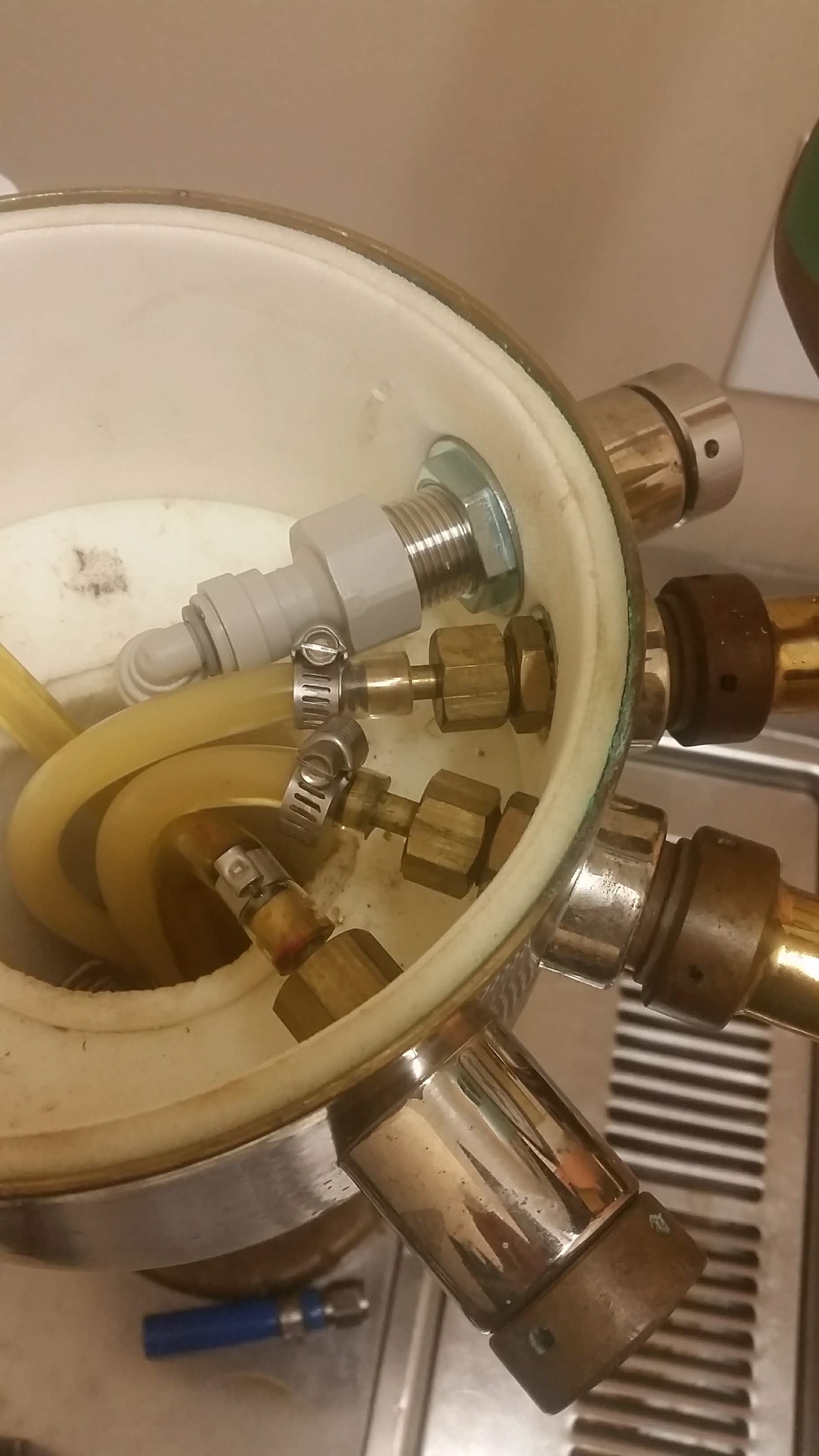

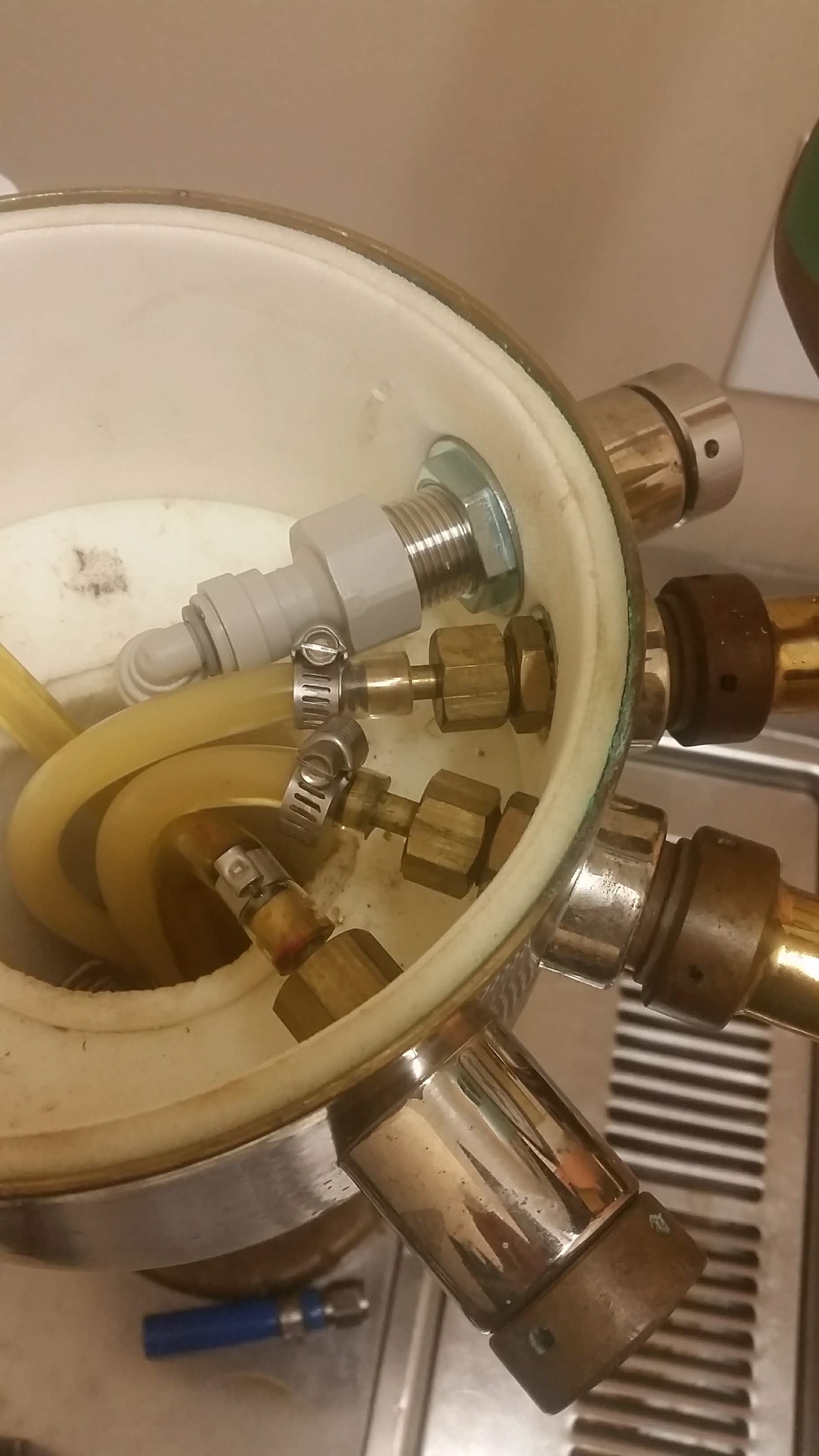

To make a long story short, drilled all the holes installed the shanks and they barely fit. When I say barely, I mean freakin' barely!

I used 12.5ft of Accuflex Bev-Seal Ultra 3/16" tubing per tap. Zip-tied it all together and made one big coil and attached to the rear wall with some Velcro straps. I'm really pleased with how it turned out and had no leaks!

Ordered up two 2-1/8" and two 3-1/8" stainless shanks (just kind of guessing at what size I would need). After receiving them and eyeballing the space I had to install them, I knew it was going to be tight. I went ahead and drilled out one of the shank holes and fitted the new shank. Still looked sketchy, but had now committed myself by drilling out that first hole. Not sure whether it was going to work, I went ahead a shopped out a standard 4-tap tower just in case. I really didn't want to spend another $250, but knew I might have to.

To make a long story short, drilled all the holes installed the shanks and they barely fit. When I say barely, I mean freakin' barely!

I used 12.5ft of Accuflex Bev-Seal Ultra 3/16" tubing per tap. Zip-tied it all together and made one big coil and attached to the rear wall with some Velcro straps. I'm really pleased with how it turned out and had no leaks!