Didn’t he harvest yeast prior to doing anything with brewing?Also, what if Nate isolated a yeast from his yard or farm to use in their beers and throw other yeast in to protect it? It’s possible..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isolated Yeast (Tree House): How to Identify and Characterize?

- Thread starter isomerization

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

No idea. I thought I read somewhere that he did. Maybe for pizza? I also did either read or saw in a video that Dean was saying Nate loves wine etc. Who knows lolDidn’t he harvest yeast prior to doing anything with brewing?

“I have been culturing yeast and making pizza since my teens, but didn’t begin brewing until my mid-twenties”No idea. I thought I read somewhere that he did. Maybe for pizza? I also did either read or saw in a video that Dean was saying Nate loves wine etc. Who knows lol

Im not convinced this plays a part but I always thought it was interesting that the brewer who’s beer is so focused on yeast esters, also has a history of yeast outside of brewing.

https://beerconnoisseur.com/articles/nate-lanier-tree-house-brewing

Norseninja

Member

- Joined

- Aug 4, 2015

- Messages

- 8

- Reaction score

- 0

Does not surprise really. Larry Bell of Bells in Michigan got his start in the bakery business and created his own yeast strain.

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 171

- Reaction score

- 82

If that will be true we will have seen other yeasts in their cans already as we are highly confident they don’t pasteurize, filter or centrifuge (very unlikely they owned an expensive zero oxygen centrifuge 10+ years ago when some of these beers were conceived via homebrewing). Also, pasteurization, filtration and centrifugation will be detrimental to some of the quality attributes and mouthfeel they are seeking in the first place. Additionally, if any were true we will not be seeing any yeasts or dregs in the cans in the first place. And finally, adding risk to the quality of their product by tampering just to hide a yeast strain will be counterintuitive for someone who understands the most important element is their process and not the ingredients.

At some point we have to realize that in order to keep things simple and consistent, the most plausible explanation is they use commercially available, reliable, and well characterized beer yeasts within a controlled process intended to enhance yeast flavor contribution and perfect balance between all other ingredients. Just because we can’t land on their beer profile and sensory using regular homebrewing techniques doesn’t necessarily mean there is some mysterious element or special ingredient that goes into their brew - as I said before, maybe we have to open our minds and look into other alternative processes and prove them right or wrong...

At some point we have to realize that in order to keep things simple and consistent, the most plausible explanation is they use commercially available, reliable, and well characterized beer yeasts within a controlled process intended to enhance yeast flavor contribution and perfect balance between all other ingredients. Just because we can’t land on their beer profile and sensory using regular homebrewing techniques doesn’t necessarily mean there is some mysterious element or special ingredient that goes into their brew - as I said before, maybe we have to open our minds and look into other alternative processes and prove them right or wrong...

You keep referring to consistency as part of their focus, but we’re discussing a brewery who has struggled with consistency more than any other brewery I can think of.If that will be true we will have seen other yeasts in their cans already as we are highly confident they don’t pasteurize, filter or centrifuge (very unlikely they owned an expensive zero oxygen centrifuge 10+ years ago when some of these beers were conceived via homebrewing). Also, pasteurization, filtration and centrifugation will be detrimental to some of the quality attributes and mouthfeel they are seeking in the first place. Additionally, if any were true we will not be seeing any yeasts or dregs in the cans in the first place. And finally, adding risk to the quality of their product by tampering just to hide a yeast strain will be counterintuitive for someone who understands the most important element is their process and not the ingredients.

At some point we have to realize that in order to keep things simple and consistent, the most plausible explanation is they use commercially available, reliable, and well characterized beer yeasts within a controlled process intended to enhance yeast flavor contribution and perfect balance between all other ingredients. Just because we can’t land on their beer profile and sensory using regular homebrewing techniques doesn’t necessarily mean there is some mysterious element or special ingredient that goes into their brew - as I said before, maybe we have to open our minds and look into other alternative processes and prove them right or wrong...

I get your point, but at the end of the day they are doing something that is resulting in a very different product. To do that its likely they are using an ingredient we haven‘t discovered, or using a process very different than what most of us are doing. If it was as simple as blending finished beer from the three yeasts discussed, someone would’ve reproduced it.

beervoid

Hophead & Pellet Rubber

So we know ferulic acid gives us clove. Clove is what we dont want. How do we reduce ferulic acid in our wort?

Are there enzymes that eat up ferulic acid?

Its an acid? Maybe a certain salt removes it?

On the forum there different opinions on making t58 less clove. Somr say its not a spicy yeast to begin with.

I mailed fermentis how to reduce clove they answered, ferment high but you will always get some light spice. They have never run any tests on t58 on this subject.

Can naturally carbing make the beer less clove?

Do we perhaps need to reduce the clove in the other yeast now presumed to be wb06?

Maybe if we get enough bubblegum and fruit of of each "ester" yeast they will push away the clove?

Wb06 is more spicy.

I just pitched 1.5 package of s04 on its own and 1.5 package of s04 together with 1gr t58 at 18c and freerise to 22 for 2 batches to compare what t58 brings.

Are there enzymes that eat up ferulic acid?

Its an acid? Maybe a certain salt removes it?

On the forum there different opinions on making t58 less clove. Somr say its not a spicy yeast to begin with.

I mailed fermentis how to reduce clove they answered, ferment high but you will always get some light spice. They have never run any tests on t58 on this subject.

Can naturally carbing make the beer less clove?

Do we perhaps need to reduce the clove in the other yeast now presumed to be wb06?

Maybe if we get enough bubblegum and fruit of of each "ester" yeast they will push away the clove?

Wb06 is more spicy.

I just pitched 1.5 package of s04 on its own and 1.5 package of s04 together with 1gr t58 at 18c and freerise to 22 for 2 batches to compare what t58 brings.

Wb06 is more clove than spice from my experience. T58 in small % was not that noticeable for me depending on how it was used. I would have to look back at my notes but every beer with wb was not what we are looking for. The clove ruined it. I think we just need to experiment more and take risks. I suggest you guys go back to the beginning of the thread and just read through. A lot of what you guys are bringing up recently was already discussed. Also, there are tons of other yeasts that produce bubble gum and fruit Searching for yeast that creates the bubble gum flavor check this thread. I have a baby on the way so when I have time I’m going to experiment more and I suggest you all do the same. Try other yeast and don’t be scared. Just do it!

echoALEia

Well-Known Member

@Clyde McCoy @isomerization that have tested cans. We’re the cans kept cold the whole time or shipped across the US in the summer heat? Maybe this has something to do with what’s showing up in the cans? Maybe some yeast are dying due to heat?

I shipped a couple of cans to Clyde. I used a box left over from Omega yeast - styrofoam on all four sides with a cooling pack. @Clyde McCoy can answer if they were too warm.

echoALEia

Well-Known Member

Wb06 is more clove than spice from my experience. T58 in small % was not that noticeable for me depending on how it was used. I would have to look back at my notes but every beer with wb was not what we are looking for. The clove ruined it. I think we just need to experiment more and take risks. I suggest you guys go back to the beginning of the thread and just read through. A lot of what you guys are bringing up recently was already discussed. Also, there are tons of other yeasts that produce bubble gum and fruit Searching for yeast that creates the bubble gum flavor check this thread. I have a baby on the way so when I have time I’m going to experiment more and I suggest you all do the same. Try other yeast and don’t be scared. Just do it!

Just brewed a batch with underpitched S04 @ 66F - I’m getting a fair amount of bubble gum in the aroma now - still fermenting and it’s free rising now

How much did you pitch and what’s the volume and OG?Just brewed a batch with underpitched S04 @ 66F - I’m getting a fair amount of bubble gum in the aroma now - still fermenting and it’s free rising now

echoALEia

Well-Known Member

90g (as opposed to 137g) 35gallons & 1.074 was my measured OGHow much did you pitch and what’s the volume and OG?

beervoid

Hophead & Pellet Rubber

So 8 packs? Did you have any lag time before fermentation started?90g (as opposed to 137g) 35gallons & 1.074 was my measured OG

echoALEia

Well-Known Member

It was fermenting within 24 hoursSo 8 packs? Did you have any lag time before fermentation started?

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,032

- Reaction score

- 2,131

There is no WB-06 in their beers. We need to move on from this.

Beers that finish at 1.015 don’t have a diastaticus yeast in them. They would have exploding cans all the time and phenols would eventually take over. Who has seen a review of an old Tree House can that’s a phenolic mess.

Beers that finish at 1.015 don’t have a diastaticus yeast in them. They would have exploding cans all the time and phenols would eventually take over. Who has seen a review of an old Tree House can that’s a phenolic mess.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 202

- Reaction score

- 231

There is no WB-06 in their beers. We need to move on from this.

Beers that finish at 1.015 don’t have a diastaticus yeast in them. They would have exploding cans all the time and phenols would eventually take over. Who has seen a review of an old Tree House can that’s a phenolic mess.

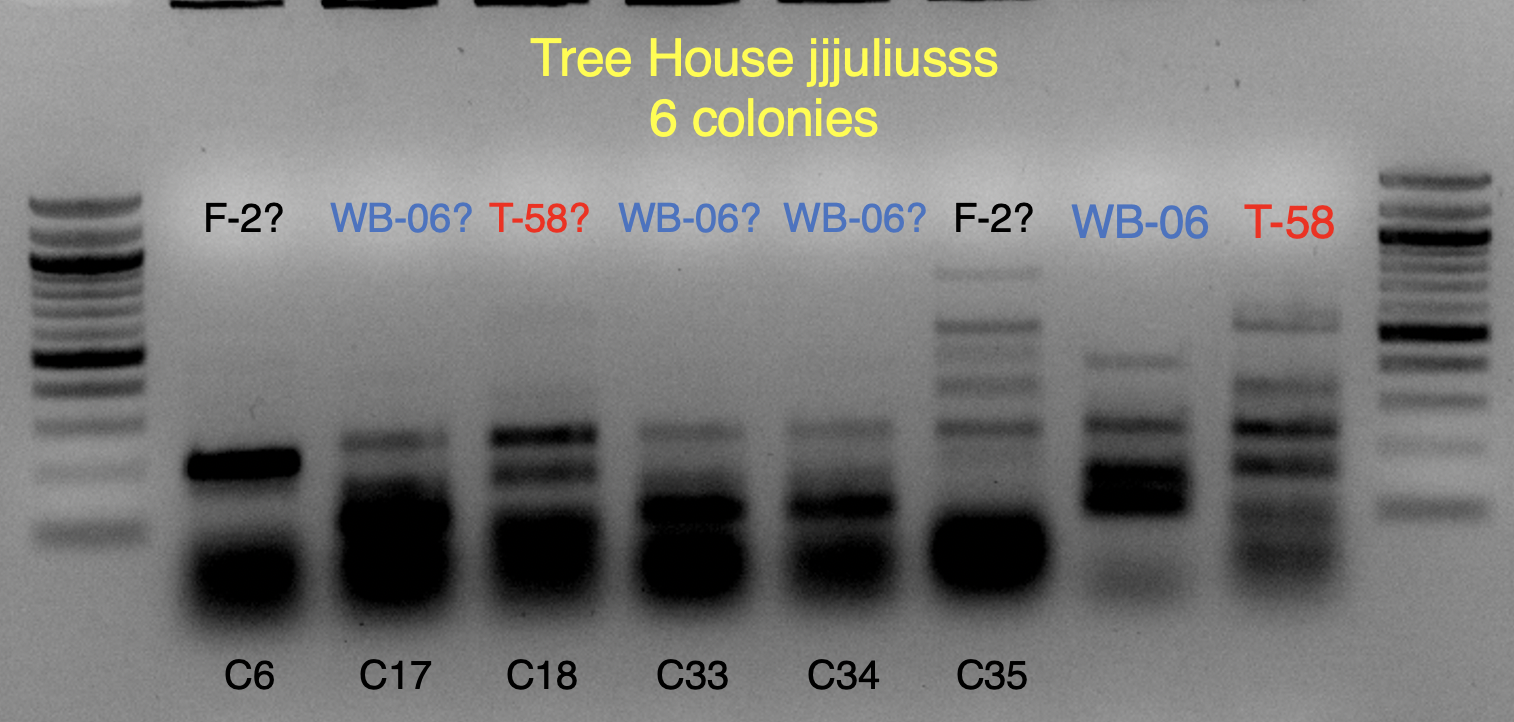

Maybe. Maybe not. This was the most recent test I did (looks inconclusive to me):

Will test more when I have the time.

beervoid

Hophead & Pellet Rubber

There was that blog that tested and was convinced there is wb06. You think his results where wrong or there is another yeast with the same signature? He seems pretty sure of his case.There is no WB-06 in their beers. We need to move on from this.

Beers that finish at 1.015 don’t have a diastaticus yeast in them. They would have exploding cans all the time and phenols would eventually take over. Who has seen a review of an old Tree House can that’s a phenolic mess.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 202

- Reaction score

- 231

There was that blog that tested and was convinced there is wb06. You think his results where wrong or there is another yeast with the same signature? He seems pretty sure of his case.

I’ve also seen that. He failed to detect S-04 which I’ve found more than 80 times.

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,032

- Reaction score

- 2,131

@Clyde McCoy I’d be interested to see what wlp644 or Sacch Trois looks like on PCR. According to the yeast genome tree it’s very closely related to WB-06 which I find kinda hard to believe but that’s what it shows. I know @isomerization tested it but he said his sample might have been compromised I believe.

Sacch Trois is supposedly diastaticus but at very low levels of activity. Clearly there’s no dried version so that would be weird to have dry yeast and liquid combined but it’s easier to believe than WB-06 in my book. WB-06 takes over and flattens hops completely.

Nate has said he doesn’t use dextrose in any double ipa other than Bright. It would be hard to get S04 (and T-58 for that matter) to hit that level of attenuation without dextrose so there is definitely something that eats more complex sugars.

Sacch Trois is supposedly diastaticus but at very low levels of activity. Clearly there’s no dried version so that would be weird to have dry yeast and liquid combined but it’s easier to believe than WB-06 in my book. WB-06 takes over and flattens hops completely.

Nate has said he doesn’t use dextrose in any double ipa other than Bright. It would be hard to get S04 (and T-58 for that matter) to hit that level of attenuation without dextrose so there is definitely something that eats more complex sugars.

beervoid

Hophead & Pellet Rubber

Good point. Perhaps with overpitching?@Clyde McCoy I’d be interested to see what wlp644 or Sacch Trois looks like on PCR. According to the yeast genome tree it’s very closely related to WB-06 which I find kinda hard to believe but that’s what it shows. I know @isomerization tested it but he said his sample might have been compromised I believe.

Sacch Trois is supposedly diastaticus but at very low levels of activity. Clearly there’s no dried version so that would be weird to have dry yeast and liquid combined but it’s easier to believe than WB-06 in my book. WB-06 takes over and flattens hops completely.

Nate has said he doesn’t use dextrose in any double ipa other than Bright. It would be hard to get S04 (and T-58 for that matter) to hit that level of attenuation without dextrose so there is definitely something that eats more complex sugars.

Have you tested the FG of some Tree House DIPA?

With a step mash, proper oxygen, and proper nutrients it’s actually pretty easy to get S04 to attenuate from the low/mid 1.070’s down to the 1.012-1.015 range.Nate has said he doesn’t use dextrose in any double ipa other than Bright. It would be hard to get S04 (and T-58 for that matter) to hit that level of attenuation without dextrose so there is definitely something that eats more complex sugars.

I’ve struggled to accomplish this, slightly underpitching s04, which I think we’re pretty sure Nate does. Didn’t add oxygen thoughWith a step mash, proper oxygen, and proper nutrients it’s actually pretty easy to get S04 to attenuate from the low/mid 1.070’s down to the 1.012-1.015 range.

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,032

- Reaction score

- 2,131

Yeah I guess you could get to 8%. It’s at the higher end of S04’s range. I make like two 8% beers a year so I never really worry about it.

Yeah I guess you could get to 8%. It’s at the higher end of S04’s range. I make like two 8% beers a year so I never really worry about it.

Ya, SO4 is really a pretty strong attenuator, especially considering how well it flocculates. All you really need is a 30-40 minute mash step at 146-149, and then another step at 163 for the body. Just oxygenate and add nutrients as you would for a similar liquid yeast.I’ve struggled to accomplish this, slightly underpitching s04, which I think we’re pretty sure Nate does. Didn’t add oxygen though

I still think there is something in their beers other than S04, but you should be able to get 90-95% of the way there with it. I think they are just treating it differently than we typically do.

Lakeside_Brewer5

Member

- Joined

- Sep 18, 2020

- Messages

- 23

- Reaction score

- 12

I live 40 minutes from Treehouse and they are the reason I enjoy craft beer as much as I do. I've been lurking on this thread since I started homebrewing recently, and from reading through it all, it seems @echoALEia has been the closest of anyone yet, even feeling like he had it perfect for a day before flavor and aroma changed. His post #3099 should be the basis with which more experiments are done.

A few key points are that he did use a simple blending by adding the T58 and WB06 wort to the main ferment with the dry hop. Going off his results, fermenting a small portion of the original wort with T58 and WB06 for 12-24 hours before pitching CBC-1 or F2 to kill it may be the solution. If one waited another 24 hours or so for the slaughter to complete, in theory all the diastaticus WB06 is now dealt with and you could then transfer to the main FV that was pitched with only S04. The dry hop can be done at this time, as well, or after. The key is timing so the S04 is mostly or completely finished fermentation when this is done.

This solves many problems, but specifically the following:

1) WB06 no longer over attenuates

2) WB06 doesn't destroy the hop flavor and aroma (this is my theory as to why @echoALEia found after a day it had changed, the killer strain didn't have a chance to do its job)

3) If the sweet spot is found, that small volume of wort will contain heavy banana flavor, which is a key part of the flavor profile of bubble gum, which most agree is something you get from a treehouse beer.

A major interaction that needs to be known is how long does it take the CBC-1 to die or go dormant? It would only need to be pitched in small quantities within the small volume prior to blending because the T58 and WB06 wort would only make up ~10% of the overall volume, but it leaves open the question of why we see almost exclusively S04 yeast and not the killer strain.

Based on reading Scott Janish's "Esters and Fusel Alcohols" I tend to think fermentation for both the main FV volume, and small 10% volume needs to be started at high temp for 2.5 days and then dropped to 60-62 to maximize the esters we're getting out of the underpitched S04 especially.

I think its important to consider how Nate got his start and how these recipes would've evolved between Monson and now because as they've scaled heavily the last few years, its unlikely Nate has messed with the recipes of core beers as opposed to just scaling them.

Also, much appreciation for @isomerization and @Clyde McCoy for the work they've done in really getting to the microbiology level of this.

A few key points are that he did use a simple blending by adding the T58 and WB06 wort to the main ferment with the dry hop. Going off his results, fermenting a small portion of the original wort with T58 and WB06 for 12-24 hours before pitching CBC-1 or F2 to kill it may be the solution. If one waited another 24 hours or so for the slaughter to complete, in theory all the diastaticus WB06 is now dealt with and you could then transfer to the main FV that was pitched with only S04. The dry hop can be done at this time, as well, or after. The key is timing so the S04 is mostly or completely finished fermentation when this is done.

This solves many problems, but specifically the following:

1) WB06 no longer over attenuates

2) WB06 doesn't destroy the hop flavor and aroma (this is my theory as to why @echoALEia found after a day it had changed, the killer strain didn't have a chance to do its job)

3) If the sweet spot is found, that small volume of wort will contain heavy banana flavor, which is a key part of the flavor profile of bubble gum, which most agree is something you get from a treehouse beer.

A major interaction that needs to be known is how long does it take the CBC-1 to die or go dormant? It would only need to be pitched in small quantities within the small volume prior to blending because the T58 and WB06 wort would only make up ~10% of the overall volume, but it leaves open the question of why we see almost exclusively S04 yeast and not the killer strain.

Based on reading Scott Janish's "Esters and Fusel Alcohols" I tend to think fermentation for both the main FV volume, and small 10% volume needs to be started at high temp for 2.5 days and then dropped to 60-62 to maximize the esters we're getting out of the underpitched S04 especially.

I think its important to consider how Nate got his start and how these recipes would've evolved between Monson and now because as they've scaled heavily the last few years, its unlikely Nate has messed with the recipes of core beers as opposed to just scaling them.

Also, much appreciation for @isomerization and @Clyde McCoy for the work they've done in really getting to the microbiology level of this.

echoALEia

Well-Known Member

Funny you mention that post, because I brewed that same recipe for the first time since I last posted it, but I’ve been same basic process for all my recipes. I dry hop cooler now. This time around I underpitched the SO4 and it’s smelling amazing so far. I’ll be dry hopping it on Sunday.I live 40 minutes from Treehouse and they are the reason I enjoy craft beer as much as I do. I've been lurking on this thread since I started homebrewing recently, and from reading through it all, it seems @echoALEia has been the closest of anyone yet, even feeling like he had it perfect for a day before flavor and aroma changed. His post #3099 should be the basis with which more experiments are done.

A few key points are that he did use a simple blending by adding the T58 and WB06 wort to the main ferment with the dry hop. Going off his results, fermenting a small portion of the original wort with T58 and WB06 for 12-24 hours before pitching CBC-1 or F2 to kill it may be the solution. If one waited another 24 hours or so for the slaughter to complete, in theory all the diastaticus WB06 is now dealt with and you could then transfer to the main FV that was pitched with only S04. The dry hop can be done at this time, as well, or after. The key is timing so the S04 is mostly or completely finished fermentation when this is done.

This solves many problems, but specifically the following:

1) WB06 no longer over attenuates

2) WB06 doesn't destroy the hop flavor and aroma (this is my theory as to why @echoALEia found after a day it had changed, the killer strain didn't have a chance to do its job)

3) If the sweet spot is found, that small volume of wort will contain heavy banana flavor, which is a key part of the flavor profile of bubble gum, which most agree is something you get from a treehouse beer.

A major interaction that needs to be known is how long does it take the CBC-1 to die or go dormant? It would only need to be pitched in small quantities within the small volume prior to blending because the T58 and WB06 wort would only make up ~10% of the overall volume, but it leaves open the question of why we see almost exclusively S04 yeast and not the killer strain.

Based on reading Scott Janish's "Esters and Fusel Alcohols" I tend to think fermentation for both the main FV volume, and small 10% volume needs to be started at high temp for 2.5 days and then dropped to 60-62 to maximize the esters we're getting out of the underpitched S04 especially.

I think its important to consider how Nate got his start and how these recipes would've evolved between Monson and now because as they've scaled heavily the last few years, its unlikely Nate has messed with the recipes of core beers as opposed to just scaling them.

Also, much appreciation for @isomerization and @Clyde McCoy for the work they've done in really getting to the microbiology level of this.

A couple of observations since that last post. While I know a huge part of the TH flavors are esters from the yeast and malts, I truly believe that they do a terrific job at suspending hop oils. That would explain why it tasted amazing right after hopping with the hop cannon. What I’ve been doing lately is “see sawing” the mixture - injecting the krausen and hops into the main ferment with pressure, then injecting back into the hop cannon one more time to clear out any residual hops. No - not a hint of oxidation. I’ve found I’m getting the best hop saturation. This way. I think this can be achieved on the homebrew level simply but adding the dry hops and krausen to the keg and shaking the hell out of it. Definitely use a CBDS type device!

I really think troxerX is onto something with blending. It’s an expansion on what I’m doing basically - it’s easier to control and can be utilized for multiple batches.

beervoid

Hophead & Pellet Rubber

With shaking I would be worried with over extraction and getting too much yeast in suspension, but I think you can dump through the bottom right?Funny you mention that post, because I brewed that same recipe for the first time since I last posted it, but I’ve been same basic process for all my recipes. I dry hop cooler now. This time around I underpitched the SO4 and it’s smelling amazing so far. I’ll be dry hopping it on Sunday.

A couple of observations since that last post. While I know a huge part of the TH flavors are esters from the yeast and malts, I truly believe that they do a terrific job at suspending hop oils. That would explain why it tasted amazing right after hopping with the hop cannon. What I’ve been doing lately is “see sawing” the mixture - injecting the krausen and hops into the main ferment with pressure, then injecting back into the hop cannon one more time to clear out any residual hops. No - not a hint of oxidation. I’ve found I’m getting the best hop saturation. This way. I think this can be achieved on the homebrew level simply but adding the dry hops and krausen to the keg and shaking the hell out of it. Definitely use a CBDS type device!

I really think troxerX is onto something with blending. It’s an expansion on what I’m doing basically - it’s easier to control and can be utilized for multiple batches.

How much contact time do you give the hops?

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 171

- Reaction score

- 82

@Lakeside_Brewer5 good luck my friend!. This is exactly what I’ve been saying all this time but unfortunately no one will listen - my blending theory - you brew bready batch 1 and ferment with yeast A. You brew high gravity batch 2 loaded with wheat a.k.a German weiss and ferment with yeast B and C to maximize those ethyl acetates. You crash yeasts B and C and add yeast D to kill. Then Blend batch 1 and 2 and then as an extra you brew batch 3 with either yeast A or D and lots of caramel and pale notes and when at high krausen blend with batch 1 + 2 to condition. With what I’ve been saying all this time you get the bread, the banana-bubblegum and the caramel all in one with simple ingredients. Again, I’ve been putting the answer out there but no one wants to listen as there is nothing magical is special about my proposal.

beervoid

Hophead & Pellet Rubber

Have you tested this yet, or are planning to?@Lakeside_Brewer5 good luck my friend!. This is exactly what I’ve been saying all this time but unfortunately no one will listen - my blending theory - you brew bready batch 1 and ferment with yeast A. You brew high gravity batch 2 loaded with wheat a.k.a German weiss and ferment with yeast B and C to maximize those ethyl acetates. You crash yeasts B and C and add yeast D to kill. Then Blend batch 1 and 2 and then as an extra you brew batch 3 with either yeast A or D and lots of caramel and pale notes and when at high krausen blend with batch 1 + 2 to condition. With what I’ve been saying all this time you get the bread, the banana-bubblegum and the caramel all in one with simple ingredients. Again, I’ve been putting the answer out there but no one wants to listen as there is nothing magical is special about my proposal.

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 171

- Reaction score

- 82

Have you tested this yet, or are planning to?

in-progress as I type but as I said, will not share details until I see others rolling up their sleeves.... @isomerization, @Clyde McCoy busted their ..... giving us the microbiology, now it’s time for others to get out of their ‘one wort’ world and help Joe @echoALEia and myself prove this right or wrong. No teamwork - no recipe...

Lakeside_Brewer5

Member

- Joined

- Sep 18, 2020

- Messages

- 23

- Reaction score

- 12

I can’t speak for @troxerX but I’ll be testing the slightly simplified version I proposed in my original post. Should be starting it in a few weeks. I don’t have the professional setup @echoALEia has but I’ll focused on minimizing oxidation during the blending process.Have you tested this yet, or are planning to?

Based on the use of Brite Tanks at TH, and how we’ve seen the randomness of pitching a yeast blend all at once, I’m not firmly in the camp multiple worts are being fermented and used until we have evidence otherwise.

Noob_Brewer

Well-Known Member

@echoALEia Ive asked this before somewhere in HBT with no response though. How do you know how many cells are in a packet of SO4 to know you are under pitching? Fermentis states is 6B cells per gram, but if you go by Mr. Malty standards, its 20B cells. So this is tremendous variation. What do you go by to know you are under pitching and what do you think your pitch rate actually is? Thanks.This time around I underpitched the SO4 and it’s smelling amazing so far. I’ll be dry hopping it on Sunday.

beervoid

Hophead & Pellet Rubber

Fair enough, I'll def be joining. Been experimenting with copitching but havent had any cutting edge results.in-progress as I type but as I said, will not share details until I see others rolling up their sleeves.... @isomerization, @Clyde McCoy busted their ..... giving us the microbiology, now it’s time for others to get out of their ‘one wort’ world and help Joe @echoALEia and myself prove this right or wrong. No teamwork - no recipe...

View attachment 699100

I think we also need to focus more on how to retain esters in our worts. They are super volatile. I recently read and article that belgium brewers take the beer off the yeast as soon as possible in order to retain yeast esters as old yeasts absorb them. I wonder how this ties in with conditioning.

Especially considering these beers have tons of hops and enzymes that cause hop creep it seems tricky to get the beer off the yeast early as to prevent diacetyl from forming. Conditioning the beer with another yeast seems to me the answer to take care of the hop creep problem.

Unless they cheat and use ALDC

"One wort order" its a good one, made me laugh.

LOL. If you don’t want to share your recipe bud, don’t share your recipe. There’s been a lot of people who contributed to this thread, who shared beer, who shipped beer to be test, etc. You through out an idea that was also thrown out about 80 pages ago. Nothing wrong with that, but let’s not act like you’re the only one contributing.in-progress as I type but as I said, will not share details until I see others rolling up their sleeves.... @isomerization, @Clyde McCoy busted their ..... giving us the microbiology, now it’s time for others to get out of their ‘one wort’ world and help Joe @echoALEia and myself prove this right or wrong. No teamwork - no recipe...

View attachment 699100

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 171

- Reaction score

- 82

LOL. If you don’t want to share your recipe bud, don’t share your recipe. There’s been a lot of people who contributed to this thread, who shared beer, who shipped beer to be test, etc. You through out an idea that was also thrown out about 80 pages ago. Nothing wrong with that, but let’s not act like you’re the only one contributing.

As you can imagine by now I have pretty a good idea how whoever threw that idea 80 pages ago was ignored... we would probably have a good recipe by now... I’m about team work and cooperation and as you can see I have to get creative to convince the right people so we get results...

As previously mentioned, I didn’t ignore. I was convinced that was the way to go and tried a couple batches. It made a good beer but wasn’t anything like TH. Very strong esters from the other 2 yeasts. They faded and became subtle very quickly. That being said, it was in my beginning stages of brewing, I didn’t have great oxygen control, was brewing in carboys. All things considered it made a good beer, but I wasn’t convinced this technique would produce anything with a TH profile.As you can imagine by now I have pretty a good idea how whoever threw that idea 80 pages ago was ignored... we would probably have a good recipe by now... I’m about team work and cooperation and as you can see I have to get creative to convince the right people so we get results...

beervoid

Hophead & Pellet Rubber

From being strong to fading out they never where even a bit close to TH esters?As previously mentioned, I didn’t ignore. I was convinced that was the way to go and tried a couple batches. It made a good beer but wasn’t anything like TH. Very strong esters from the other 2 yeasts. They faded and became subtle very quickly. That being said, it was in my beginning stages of brewing, I didn’t have great oxygen control, was brewing in carboys. All things considered it made a good beer, but I wasn’t convinced this technique would produce anything with a TH profile.

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 171

- Reaction score

- 82

Fair enough, I'll def be joining. Been experimenting with copitching but havent had any cutting edge results.

I think we also need to focus more on how to retain esters in our worts. They are super volatile. I recently read and article that belgium brewers take the beer off the yeast as soon as possible in order to retain yeast esters as old yeasts absorb them. I wonder how this ties in with conditioning.

Especially considering these beers have tons of hops and enzymes that cause hop creep it seems tricky to get the beer off the yeast early as to prevent diacetyl from forming. Conditioning the beer with another yeast seems to me the answer to take care of the hop creep problem.

Unless they cheat and use ALDC

"One wort order" its a good one, made me laugh.

LOL ‘First Wort Order‘ —

Agreed, we need to understand more about esters, how they are formed and how to retain as much as possible.

With the blending approach, esters are taken care of, which is another advantage of the blending process. Larger Batch 1 ferments as usual, this batch purpose is to add the bread notes and base malt and serves as the primary hop platform, this batch will take the longest time as it needs to be dry hopped several times. Batch 2 is the ester batch with the ethyl-acetate (bubblegum) and isoamyl-acetate (banana). Per ‘BYO Hefeweizen’, fermentation for optimal notes should be done at 62F (slow ferm to avoid losing too many aromatics?) and with a higher ratio of glucose to maltose (here we go with the TH doesn’t use dextrose conversation again...). Maybe the simple sugars (glucose, dextrose, sucrose) aid in the formation of some esters? - anyway BYO doesn’t explain why. Per other references I’ve seen around, ethyl-acetate (bubblegum) is best produced with worts of higher gravities and with a grist of at least 65% wheat. Batch 2 once fermented it is quickly crashed, added CBC-1 for some time to kill T-58/WB-06 (to @Lakeside_Brewer5 point) and then quickly and carefully blended with the larger batch. By the time both batches are blended, batch 2 is the youngest one (if you are not pursuing batch 3) so my assumption is that the esters should still be there in sufficient concentration. Also if the gravity of the blend is high (i.e 16-18 points I would think the density may help retain esters?, anyway the important part is that the ester batch is fermented and blended after the larger batch went through the rigorous fermentation process.

No. And I’m not saying everyone would get the same results, and I’m not trying to discourage anyone from experimenting. But in my experience if you brew (for example) a Wit and poured it into a pale ale, it would taste just like what you would expect, a wit poured into a pale ale. It wouldn’t produce a new exotic flavor that didn’t exist in either of the original beers. Which brings me back to my previous point - TH has a very distinct flavor, and it’s a flavor that’s strong enough to be able to compete with heavily hopped beers. In my opinion, if was as simple as 90% flavor of this style and 10% flavor of that style, someone would’ve figured it out by now. I could easily be wrong, but that’s my guess.From being strong to fading out they never where even a bit close to TH esters?

beervoid

Hophead & Pellet Rubber

I havent had many TH but the ones I did really have a hefe/wheat beer smell to it.No. And I’m not saying everyone would get the same results, and I’m not trying to discourage anyone from experimenting. But in my experience if you brew (for example) a Wit and poured it into a pale ale, it would taste just like what you would expect, a wit poured into a pale ale. It wouldn’t produce a new exotic flavor that didn’t exist in either of the original beers. Which brings me back to my previous point - TH has a very distinct flavor, and it’s a flavor that’s strong enough to be able to compete with heavily hopped beers. In my opinion, if was as simple as 90% flavor of this style and 10% flavor of that style, someone would’ve figured it out by now. I could easily be wrong, but that’s my guess.

I poured a bit of a belgium wit bier in my neipa and wasnt impressed, the lower abv probably makes it thinner then you want so I dont know if this is worth comparison.

Similar threads

- Replies

- 76

- Views

- 16K