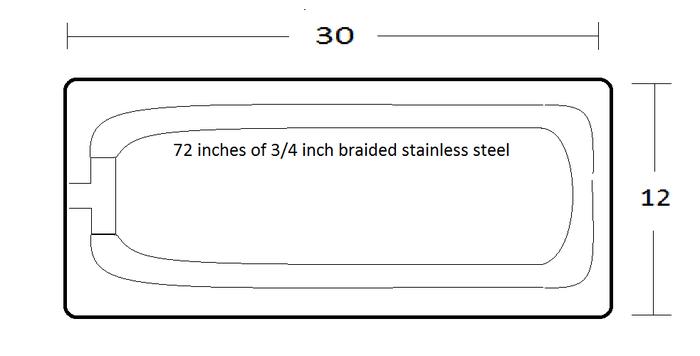

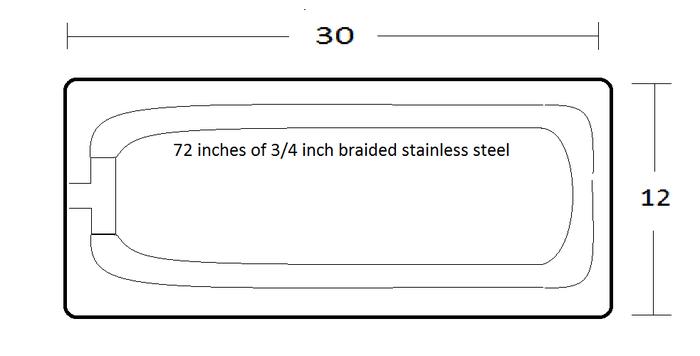

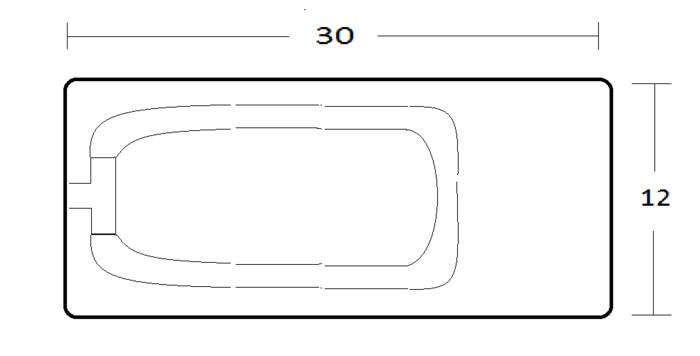

I want to get more serious about my homebrewing, and have purchased a 25 brew kettle and a 30 gallon cooler that I want to convert into a mash tun. I have a good bit of money into the pot and cooler, as you guys are aware equipment isnt cheap. I want to build my mash tun correctly but dont want to unnecessarily bulk up the mash tun if its not needed. I have a cooler thats 2 1/2 feet by 1 foot. I was planning on using 6 feet of 3/4 in braided stainless steel. Is this too much? Should I use less tubing, or the same amount but a smaller gauge. I don't know much about the process in practice (i have a biology degree and some book smarts about brewing, but thats nothing compared to actual experience). Any advice would be great. I have attached a photo of what I plan to do. Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)