hello. new member. i have been stalking the site and various ideas for diy gylcol chillers from a/c and dehumidifiers. I was wondering if anyone has made one from a counter top ice cream maker that has a built in compressor, like Cuisinart ice-50? it will hold 1.5 quarts of gylcol, will keep gycol moving, will drop to -31 degrees, and made for long duty cycle. if anyone has, pls post details and issues you had with it. thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ice Cream maker Glycol chiller

- Thread starter haclaw

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ive never seen anything like that, but, depending on how much you need to cool, a little desktop ice cream maker is going to be seriously underpowered. its only meant to chill 1/4 of a gallon. im sure it would work ok for a gallon or two (400-800% above what it was meant for), but if you are looking to cool not only several gallons of glycol, but also several kegs of beer... its going to have a tough time.

Well this is a very old thread but just found it because i was thinking the same about using a small ice cream maker as a glycol cooler. Im surprised not to find more posts about this idea. Maybe audger is right and it would be under powered. Im looking for a nice compact and inexpensive solution to cooling my cronical 7 gallon.

I built a decent chiller using Peltier chips in series, and the best I can get is about 20-25*F below ambient. which gets me to around 40* F in my house. (My basement is a pretty consistent 65* F.) I can chill my CF10, but not to the 35*F that I was hoping to.

Honestly for the money I spent building it, I would have been better off buying a clearance / craigslist window unit and building one based on any number of designs using an HVAC unit, as they can cool glycol below freezing.

YMMV.

Honestly for the money I spent building it, I would have been better off buying a clearance / craigslist window unit and building one based on any number of designs using an HVAC unit, as they can cool glycol below freezing.

YMMV.

Thanks for your reply videojunkie

Well getting to 40C with peltiers in series seems pretty good! I was also considering a peltier chip route. Do you have the cold side block connected to the wall of your fermentor? That’s what I was considering.

Or did you use the peltiers to chill a liquid to circulate?

I’m really not a fan of those concerted AC window units. I know they will provide the cooling power but they look so god awful ugly and are sort of bulky. I have my brewery set up in my man cave so I want to keep it sort of nice looking. I’d love to see some details.

Well getting to 40C with peltiers in series seems pretty good! I was also considering a peltier chip route. Do you have the cold side block connected to the wall of your fermentor? That’s what I was considering.

Or did you use the peltiers to chill a liquid to circulate?

I’m really not a fan of those concerted AC window units. I know they will provide the cooling power but they look so god awful ugly and are sort of bulky. I have my brewery set up in my man cave so I want to keep it sort of nice looking. I’d love to see some details.

Ok. I spent a lot of time diving into the peltier cooling forums, in particular the PC overclocking community before building my cooler.

I went with a 12v system so that the parts were relatively inexpensive, but it still cost about $150 to build. The most expensive individual parts being the 2 40mm heatsinks.

2 TEC-12715 chips, each sandwiched between a pc heat sink (cooler master hyper 212) and a 40mm water block. Glycol mix (I used RV water treatment) is held in a medium sized cooler, and circulates through the 2 water blocks in series, and then dumps back into the cooler.

Electrically the system runs off a 30A 12V power supply. A 12v bus runs an inkbird temperature controller, pump and the heat sink fans.

A second 12v feed goes to a DROK controllable bucker and the variable voltage output goes to the TECs in parallel.

The Inkbird temperature controller can shut off the DROK in case the glycol reservoir drops below freezing (ha!). There is also a 2nd thermometer at the output of the water blocks to ensure that they don't freeze.

I made a small case for it, the only noise is the fans for the heat sinks and the power supply.

The second picture is of an older prototype, which used a smaller cooler. It was unable to cool a fermenter due to the volume discrepancy.

I went with a 12v system so that the parts were relatively inexpensive, but it still cost about $150 to build. The most expensive individual parts being the 2 40mm heatsinks.

2 TEC-12715 chips, each sandwiched between a pc heat sink (cooler master hyper 212) and a 40mm water block. Glycol mix (I used RV water treatment) is held in a medium sized cooler, and circulates through the 2 water blocks in series, and then dumps back into the cooler.

Electrically the system runs off a 30A 12V power supply. A 12v bus runs an inkbird temperature controller, pump and the heat sink fans.

A second 12v feed goes to a DROK controllable bucker and the variable voltage output goes to the TECs in parallel.

The Inkbird temperature controller can shut off the DROK in case the glycol reservoir drops below freezing (ha!). There is also a 2nd thermometer at the output of the water blocks to ensure that they don't freeze.

I made a small case for it, the only noise is the fans for the heat sinks and the power supply.

The second picture is of an older prototype, which used a smaller cooler. It was unable to cool a fermenter due to the volume discrepancy.

Attachments

Last edited:

Wow. That’s very impressive. Seems a bit more complicated than I would have thought with all those electronic parts and controls.

Thanks! Knowing what I do now about how it works, I probably could simplify the design quite a bit. but the main reason I added all the extra thermometers and such was the math I had done indicated that I should be able to cool below freezing, but what I found is that the lower the temperature gets, the less efficient the TEC chips are, eventually they reach an equilibrium point where they don't seem to cool any more. I could probably re-visit the design and make some minor changes to get it colder than it is.

The extra thermometer was mostly so that I could monitor how well the TEC chips were cooling compared to my calculations. It will cool the water flowing through it about 1.5*F, but the volume of water it cools is small. It takes several hours (6+) for it to cool down the 3 gallons in the cooler from 65*F to 40*F, but it is pretty relentless...

Very old thread ....Well this is a very old thread but just found it because i was thinking the same about using a small ice cream maker as a glycol cooler. Im surprised not to find more posts about this idea. Maybe audger is right and it would be under powered. Im looking for a nice compact and inexpensive solution to cooling my cronical 7 gallon.

I am trying to do something similar.

I started thinking about a fridge for kegs based on an ice cream maker, but then I was afraid it wouldn't have enough power... so I decided to build a glycol-powered kegerator. At least I would have been able to cool one keg of beer, and maybe "expand the system" to control a fermenter (25 liters).

I'm still building it, so I don't know if it will work or not, but I'm confident. I found very little on the net ...

Last edited:

here you can see the prototype of the kegerator hosting 1 cornelius keg (18 litres).

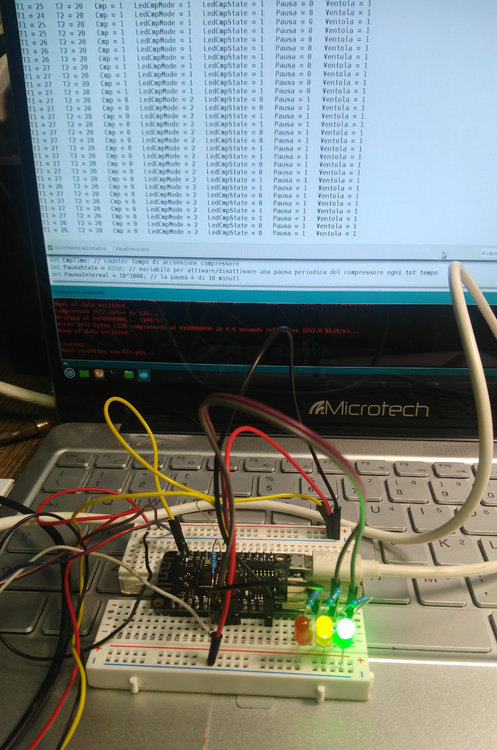

Tonite I have been working on control board. I'm using an ESP-32 to drive 3 relays (compressor, pump, fans) and two temperature probes (dallas, digital).

Full story is here: impianto a glicole, aiuto!?

Bye,

Ale-75-IT

I made some progress.

The control board is up and running. I built the power adapter with relay board to control 220v for the compressor, AC-DC converter to output 12v for fans and 5v for ESP32. I wrote a test code to control compressor, fans and glycol pump. I read glycol temp inside evaporator and heat exchanger glycol temperature, near the keg.

Re-created the heat exchanger using a longer and thinner tube, around some thin plastic (0,8mm quite invisible in photo).

I'm making some tests and I'm confident: the new exchanger performs better and glycol come back less cold to ice-cream vessel. This prevents glycol freezing inside vessel and boost performance. Now The compressor can run 30-40' before glycol start to freeze (and the control board stops compressor to let it defrost). I'm using 35% mixture to avoid to raise density.

Need more testing to confirm I can cool down a full keg to 6-7 C° in a reasonable time and mantain it without explosions, fire, or something similar... I'm sill in fear of leaving it on all night long

I apologyze for my high scool english... Bye,

Ale

The control board is up and running. I built the power adapter with relay board to control 220v for the compressor, AC-DC converter to output 12v for fans and 5v for ESP32. I wrote a test code to control compressor, fans and glycol pump. I read glycol temp inside evaporator and heat exchanger glycol temperature, near the keg.

Re-created the heat exchanger using a longer and thinner tube, around some thin plastic (0,8mm quite invisible in photo).

I'm making some tests and I'm confident: the new exchanger performs better and glycol come back less cold to ice-cream vessel. This prevents glycol freezing inside vessel and boost performance. Now The compressor can run 30-40' before glycol start to freeze (and the control board stops compressor to let it defrost). I'm using 35% mixture to avoid to raise density.

Need more testing to confirm I can cool down a full keg to 6-7 C° in a reasonable time and mantain it without explosions, fire, or something similar... I'm sill in fear of leaving it on all night long

I apologyze for my high scool english... Bye,

Ale

I whisper it.... it seems to work....

I turned it on this morning, with a room temperature of about 20C (68F).

In 12 hours it reduced the keg temperature from 13C (55.4F) to about 5C (41F). This target temperature is fine for me and I'm confident that even in summer it will do its job!

To measure the water in the keg I placed three probes in it, one at the top, one in the middle and one at the bottom, so it's accurate.

I think I will now relax a bit refining the furniture, and later I will deal with the software, that's still immature.

Bye,

Ale

I turned it on this morning, with a room temperature of about 20C (68F).

In 12 hours it reduced the keg temperature from 13C (55.4F) to about 5C (41F). This target temperature is fine for me and I'm confident that even in summer it will do its job!

To measure the water in the keg I placed three probes in it, one at the top, one in the middle and one at the bottom, so it's accurate.

I think I will now relax a bit refining the furniture, and later I will deal with the software, that's still immature.

Bye,

Ale

Last edited:

I'm going further with furniture (my second hobby after beer).

Now it looks EXACTLY as a chest freezer, but weights twice due to wood

What I like most as for now is the fan cover... it looks so technological!

I think this is what happens when you cultivate a healthy addiction to something.... you lose sight of the goal!

Bye,

Ale-75

Similar threads

- Replies

- 3

- Views

- 1K