I managed to transfer my beer from fermzilla to keg but after that I noticed I didn't have any CO2 left in my tank. Now I have keg full of beer but I have to get CO2 from store and I don't know how long it's going to take. Maybe a day or two. Can I leave my keg to a cold room @6c for a day or two?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I ran out of CO2, what now?

- Thread starter chazam

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If only there were little micro-organisms already in your beer that could make their own CO2...

But, non-facetiously, think about adding priming sugar and carbonating this batch naturally. Give the yeast something to do, maybe use up the oxygen in the headspace, get a jump-start on carbonation before you hook your tank up. Win-win.

But, non-facetiously, think about adding priming sugar and carbonating this batch naturally. Give the yeast something to do, maybe use up the oxygen in the headspace, get a jump-start on carbonation before you hook your tank up. Win-win.

If you can get explicit food grade CO2, that's awesome. If you just get generic CO2, it will probably be just fine. I live in Gabon, and the only CO2 provider is an industrial gas mixer that mostly supplies oxygen for hospitals and offshore oil rigs, and they'd laugh if I asked for food grade gas. I'm sure the booze in the beer is far less healthy than any contaminates in the gas itself.

No it isn't the same. Beverage grade CO2 has additional quality control checks, to ensure its purity therefore its suitability for human consumption.

I was going to write one more reply but it didn't go through. I decided to travel three hours to get the food grade CO2, lol. It's going to be 8-9 hours from now till I can attach a filled gas bottle. I did read something about possible contamination. I don't know what the contamination could be when filling my brewferm CO2 bottle with industrial CO2, can someone tell? Seriously curious.

Everytime I've tried to use natural carbonation I've messed up. I don't want to do it at the moment even a tiny bit.If only there were little micro-organisms already in your beer that could make their own CO2...

But, non-facetiously, think about adding priming sugar and carbonating this batch naturally. Give the yeast something to do, maybe use up the oxygen in the headspace, get a jump-start on carbonation before you hook your tank up. Win-win.

If you can get explicit food grade CO2, that's awesome. If you just get generic CO2, it will probably be just fine. I live in Gabon, and the only CO2 provider is an industrial gas mixer that mostly supplies oxygen for hospitals and offshore oil rigs, and they'd laugh if I asked for food grade gas. I'm sure the booze in the beer is far less healthy than any contaminates in the gas itself.

Alright, so you're not the only one saying that they use industrial CO2. Someone in local filling station even said that someone there uses industrial CO2 at least when serving beer.

I don't want to take the risk of contamination now though because I've have bad batches so far going back five batches backwards from current batch. They were probably due to temperature or oxygenation.

Last edited:

- Joined

- Mar 10, 2021

- Messages

- 2,713

- Reaction score

- 2,336

My son kegs and routinely just leaves beer in the carboy for long periods of time until he frees up another tap on his keezer. If you had any amount of CO2 to purge the keg you put the beer in, you are probably good for quite a while. At least as long as any other kegged beer will last...... I'd expect.

Those that don't sell their CO2 as food safe probably don't take the extra care that might be needed to ensure they never contaminate their transfer system with other gasses or even entirely give you some other gas. Whether that's a big issue for health I don't know.

Those that don't sell their CO2 as food safe probably don't take the extra care that might be needed to ensure they never contaminate their transfer system with other gasses or even entirely give you some other gas. Whether that's a big issue for health I don't know.

Last edited:

I talked about this with a guy in the brewing store. He said that I'd need an adapter with the sodastream bottle thus It'd be better just to get another 2kg brewferm CO2 bottle thus everything is more cost-efficient. Now, sodastream bottle would be handy though with a small partykeg.It's always handy to have a small sodastream CO2 bottle as a backup.

My son kegs and routinely just leaves beer in the carboy for long periods of time until he frees up another tap on his keezer.

It's probably alright then. I'm not gonna hurry up getting back to the keg to carbonate it.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

Yeah, I went for two 2kg cylinders. Then opted for a sodastream back-up, when they both ran out  Either a very cheap adaptor or a mini regulator specifically for a sodastream bottle. As I naturally carb all my beers these days, and sodastream bottles are available locally, usually on offer, I don't bother refilling the 2kg cylinders anymore. With a 3-hour round trip it's more expensive. Once you have a sodastream bottle (paid a deposit) a refill is cheap. I've got 3 bottles now. Exchange the empties whenever there's a good deal. Haven't run out since switching.

Either a very cheap adaptor or a mini regulator specifically for a sodastream bottle. As I naturally carb all my beers these days, and sodastream bottles are available locally, usually on offer, I don't bother refilling the 2kg cylinders anymore. With a 3-hour round trip it's more expensive. Once you have a sodastream bottle (paid a deposit) a refill is cheap. I've got 3 bottles now. Exchange the empties whenever there's a good deal. Haven't run out since switching.

E: Nevermind, it went away after I momentarily lifter the bars to four and went back to 1,57 (@6c). How long would you guys carbonate in a keg? 10-14d?

I just hooked the co2 to my keg. Is that noise acceptable?

It is a very tiny noise but my mic still caught it somehow.

Last edited:

I have been in the CO2 business for over 40 years. Most if not all beverage grade CO2 comes out of the same tank as industrial grade CO2. Medical grade CO2 is a different story but food grade is more concerned with the cleanliness of the cylinder than the gas. Correctly filled beverage grade CO2 cylinders are inspected for contamination on the outside of the cylinder, turned upside down for some amount of time or a residual pressure valve is installed that keeps a small amount of pressure in the cylinder to keep any contaminates from flowing back into the cylinder when it is empty. Sure if beverage grade CO2 is available use it but if you can't find it industrial grade should be fine especially if they fill your cylinder and you know it is clean inside.

In the old days, dry ice converters were used to fill CO2 cylinders which ended up putting oil into cylinders but I believe those days are past.

In the old days, dry ice converters were used to fill CO2 cylinders which ended up putting oil into cylinders but I believe those days are past.

Running out of CO2 is always an issue. Keeping a 2.5# cylinder just as a back up is an easy way to avoid the problem and have a cylinder for road trips. We always recommend them to our customers.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

Yes, beverage grade CO2 usually comes from the same industrial processes as other grades, but, after a number of well-documented and very expensive global product recalls, due to carryover contamination tainting beverage supplies, e.g., with known carcinogens, the beverage industry acknowledged **** happens and self-regulated to ensure purity of its CO2 supplies. That was years ago and subsequently guided local regulations in Europe and, I’m sure, in the US, too. In light of this, anyone risking peoples’ health by passing off CO2 as CO2 should be reported to the appropriate local authorities.

FloppyKnockers

Well-Known Member

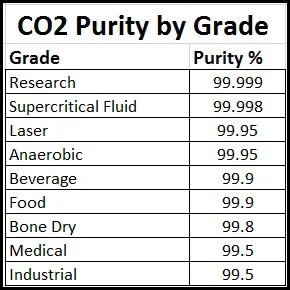

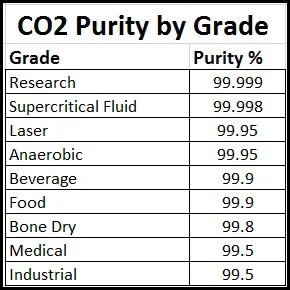

Finding gas in my area is few and far between. The local homebrew shop refills, but it's considerably more expensive per pound than the local welding shop. I looked into the different grades of CO2 and found this...

With only a .4% drop in purity, I decided to take the industrial grade - it's been fine. No off flavors, no chunks of depleted uranium, no short and curly hairs. I will continue to use the welding shop as long as they have it cheaper.

I also have a 5#er as a back-up when my 20# tank goes empty to avoid any last minute gas shortcomings.

With only a .4% drop in purity, I decided to take the industrial grade - it's been fine. No off flavors, no chunks of depleted uranium, no short and curly hairs. I will continue to use the welding shop as long as they have it cheaper.

I also have a 5#er as a back-up when my 20# tank goes empty to avoid any last minute gas shortcomings.

I have been in the CO2 business for over 40 years. Most if not all beverage grade CO2 comes out of the same tank as industrial grade CO2. Medical grade CO2 is a different story but food grade is more concerned with the cleanliness of the cylinder than the gas. Correctly filled beverage grade CO2 cylinders are inspected for contamination on the outside of the cylinder, turned upside down for some amount of time or a residual pressure valve is installed that keeps a small amount of pressure in the cylinder to keep any contaminates from flowing back into the cylinder when it is empty. Sure if beverage grade CO2 is available use it but if you can't find it industrial grade should be fine especially if they fill your cylinder and you know it is clean inside.

In the old days, dry ice converters were used to fill CO2 cylinders which ended up putting oil into cylinders but I believe those days are past.

The brewing store customer servant said that I should be able to see from regulator when the CO2 in the tank is coming to an end. Cos of my budget I hesitate buying another tank just yet.

50calshooter

Well-Known Member

- Joined

- Jan 1, 2013

- Messages

- 170

- Reaction score

- 152

Apparently the CO2 is the same whether it's for industry or food and beverage use. Only the bottles are different. Can someone verify this?

I was in the CO2 business for years. It's all the same. Carbon Dioxide is Carbon Dioxide. The whole food grade thing is just another way to get bragging rights on a product you sell. My Brewpub uses CO2 from a plane old distributor.

NightFlight

Well-Known Member

- Joined

- Nov 27, 2019

- Messages

- 159

- Reaction score

- 210

I've been using C02 from welding shops and various suppliers. None have been "food grade". I also use it on my tropical fish tanks. If anything were to die, it would be them. I'm still hale and hearty. A little hung over occasionally, but good.

- Joined

- Mar 10, 2021

- Messages

- 2,713

- Reaction score

- 2,336

While CO2 is CO2, you never know whether the people that don't sell it as food grade aren't using the manifolds and other equipment to fill your bottle with that they may have just used to fill other gases with.

Sure, it's probably not enough to really worry about. But as some are picky about a cubic inch of air getting in their fermenter, they may not want a cubic foot of O2 mixed in their CO2 bottle. Which if they don't flush the lines with the new gas before filling your tank might be a real possibility.

Welding supply houses deal with a lot of different gases. Acetylene in beer might be an interesting taste.

If they aren't willing to call it food grade, then they aren't taking the procedures to make certain things don't get mixed up. IMO.

Sure, it's probably not enough to really worry about. But as some are picky about a cubic inch of air getting in their fermenter, they may not want a cubic foot of O2 mixed in their CO2 bottle. Which if they don't flush the lines with the new gas before filling your tank might be a real possibility.

Welding supply houses deal with a lot of different gases. Acetylene in beer might be an interesting taste.

If they aren't willing to call it food grade, then they aren't taking the procedures to make certain things don't get mixed up. IMO.

PCABrewing

Recreational Brewer

- Joined

- Oct 28, 2021

- Messages

- 816

- Reaction score

- 897

Wow, talk about explosive diarrheaAcetylene in beer might be an interesting taste.

50calshooter

Well-Known Member

- Joined

- Jan 1, 2013

- Messages

- 170

- Reaction score

- 152

While CO2 is CO2, you never know whether the people that don't sell it as food grade aren't using the manifolds and other equipment to fill your bottle with that they may have just used to fill other gases with.

Sure, it's probably not enough to really worry about. But as some are picky about a cubic inch of air getting in their fermenter, they may not want a cubic foot of O2 mixed in their CO2 bottle. Which if they don't flush the lines with the new gas before filling your tank might be a real possibility.

Welding supply houses deal with a lot of different gases. Acetylene in beer might be an interesting taste.

If they aren't willing to call it food grade, then they aren't taking the procedures to make certain things don't get mixed up. IMO.

Each type of gas is dispensed through its own system. There is no all together filling system.

FloppyKnockers

Well-Known Member

The brewing store customer servant said that I should be able to see from regulator when the CO2 in the tank is coming to an end. Cos of my budget I hesitate buying another tank just yet.

That's true, but that's dumb. Sure you can see it coming to an end, but do you want to basically throw out what's left in the tank just because it's low? I can think of several analogies for this, but you get the picture.

New tanks are expensive. Keep your eye out on Craigslist for CO2 stuff. I bought a 20# steel tank, half full, with a janky regulator for $20. After it was depleted, I swapped it for a full, aluminum tank and the rest is history.

- Joined

- Mar 10, 2021

- Messages

- 2,713

- Reaction score

- 2,336

You are willing to make that statement for every supplier of gas out there?Each type of gas is dispensed through its own system. There is no all together filling system.

you've never noticed that the connectors for co2 are different vs nitrogen vs oxygen, etc. etc? i'm not an authority or someone who's worked in the industry but its pretty obvious the containers are not interchangeable...You are willing to make that statement for every supplier of gas out there?

we had a bulk liquid tank we used at our old brewery and i remember that in the process of looking for supplier initially i asked them about food grade vs industrial. i was told that because we have a big old budweiser plant, crap ton of wineries, a large amount of hospitals/medical/research activity, and a major population center that food grade was the default. i've never even seen the option of selecting your grade at praxair, matheson, airgas, etc. we also have a few refineries as well which you would think would use alot of cheaper industrial grade. but i've never seen it offered. ( i also havent ever asked for it) but the story seems to match reality in our area.

TheBluePhantom

Brewing for sport

The brewing store customer servant said that I should be able to see from regulator when the CO2 in the tank is coming to an end. Cos of my budget I hesitate buying another tank just yet.

Something to consider though. Do you trade your tank or refill it? If you get the same tank refilled each time you run into a problem eventually. An aluminum tank needs to be recertified every 5 years. I think steel is 10 years, but don't quote me. I just had mine done and it takes several weeks, the last one they forgot to call me and it was 2 months. ( I called them the day before it came back and they assured me they would call....)

A second tank to bridge the gap helps. I keep a 20 pound on the keezer, and a 5 pound in my work area. It is handy for purging and stuff. When the 20 empties out I put the 5 on the keezer until i can get to the store. If I take it to the one that sends it out it is about half the price of the one that fills on the spot. So the cost of the second tank slowly pays back for me.

no chunks of depleted uranium, no short and curly hairs

An aluminum tank needs to be recertified every 5 years. I think steel is 10 years, but don't quote me. I just had mine done and it takes several weeks, the last one they forgot to call me and it was 2 months. ( I called them the day before it came back and they assured me they would call....)

never seen a recert fee cost less than a swap.....

I have also been testing cylinders for the last 35 years and all CO2 cylinders are tested every five years. Being made from steel or aluminum makes no difference.

Something to consider though. Do you trade your tank or refill it? If you get the same tank refilled each time you run into a problem eventually. An aluminum tank needs to be recertified every 5 years. I think steel is 10 years, but don't quote me. I just had mine done and it takes several weeks, the last one they forgot to call me and it was 2 months. ( I called them the day before it came back and they assured me they would call....)

A second tank to bridge the gap helps. I keep a 20 pound on the keezer, and a 5 pound in my work area. It is handy for purging and stuff. When the 20 empties out I put the 5 on the keezer until i can get to the store. If I take it to the one that sends it out it is about half the price of the one that fills on the spot. So the cost of the second tank slowly pays back for me.

It wasn't a refill technically. It was more like a switch of brewferm tanks. We talked about the expiration date of the tanks. They said that if it's due date, they will have to inspect it somehow. So they don't like to take old tanks, but they still do. It's just more work for them.

you've never noticed that the connectors for co2 are different vs nitrogen vs oxygen, etc. etc? i'm not an authority or someone who's worked in the industry but its pretty obvious the containers are not interchangeable...

we had a bulk liquid tank we used at our old brewery and i remember that in the process of looking for supplier initially i asked them about food grade vs industrial. i was told that because we have a big old budweiser plant, crap ton of wineries, a large amount of hospitals/medical/research activity, and a major population center that food grade was the default. i've never even seen the option of selecting your grade at praxair, matheson, airgas, etc. we also have a few refineries as well which you would think would use alot of cheaper industrial grade. but i've never seen it offered. ( i also havent ever asked for it) but the story seems to match reality in our area.

CO2 is filled on its own system so cross contamination from other gases is not possible. Cleanliness of your cylinder is really what makes food grade, food grade. Most industrial grade and food grade are filled from the same tank and only medical grade and higher have any lab certification done on a batch basis. The quality of the gas is certified by the manufacturer when it is shipped out to the distributors.

Inert gases that use a CGA580 valve such as Argon and Nitrogen are often filled on a combined manifold but not CO2 with a CGA320 valve.

I fill my Co2 tanks at a nearby paintball shop. They claim their Co2 system has to be squeaky clean to protect the expensive paintball guns. I also have a paintball tank with an adapter I bought online to connect it to a Co2 regulator as a backup.While CO2 is CO2, you never know whether the people that don't sell it as food grade aren't using the manifolds and other equipment to fill your bottle with that they may have just used to fill other gases with.

Sure, it's probably not enough to really worry about. But as some are picky about a cubic inch of air getting in their fermenter, they may not want a cubic foot of O2 mixed in their CO2 bottle. Which if they don't flush the lines with the new gas before filling your tank might be a real possibility.

Welding supply houses deal with a lot of different gases. Acetylene in beer might be an interesting taste.

If they aren't willing to call it food grade, then they aren't taking the procedures to make certain things don't get mixed up. IMO.

So with Respect to cylinders, everything starts “food grade” but if it gets dirty somehow it’s now industrial? Where/how would that happen? If you bought a. used cylinder how would you know?CO2 is filled on its own system so cross contamination from other gases is not possible. Cleanliness of your cylinder is really what makes food grade, food grade. Most industrial grade and food grade are filled from the same tank and only medical grade and higher have any lab certification done on a batch basis. The quality of the gas is certified by the manufacturer when it is shipped out to the distributors.

Inert gases that use a CGA580 valve such as Argon and Nitrogen are often filled on a combined manifold but not CO2 with a CGA320 valve.

I have also been testing cylinders for the last 35 years and all CO2 cylinders are tested every five years. Being made from steel or aluminum makes no difference.

What percentage tanks fail the test?

Or how many failures a week do you typically have?

Draft Master Flash

Well-Known Member

- Joined

- Dec 20, 2021

- Messages

- 125

- Reaction score

- 78

I usually get mine filled at a welding supply store that also fills for a lot of the restaurant chains around and they claim it's all the same co2. Never had a problem. as far as getting the 5 year hydrotest, the scuba shops seem to have the quickest turn around. I keep two 20# tanks and two 5# tanks so it's not likely I will run dry. The only time I exchanged one was when the CGA320 valve on this particular tank didn't have the threads drilled to enable a "Leak Stopper" so instead of buying a new valve I just exchanged it.

DMF

DMF

TheBluePhantom

Brewing for sport

I have also been testing cylinders for the last 35 years and all CO2 cylinders are tested every five years. Being made from steel or aluminum makes no difference.

I was also taking to the guy about converting a helium to a nitrogen or argon. So details may have cross contaminated. As I said, don't quote me.

TheBluePhantom

Brewing for sport

Have you seen a place that swaps 20#? I haven't yet.never seen a recert fee cost less than a swap.....

LHBS swaps 20s.Have you seen a place that swaps 20#? I haven't yet.

hydroponic supply houses all swap 20s and 50s. (only alum tho, or at least the ones out here)

Last edited:

Similar threads

- Replies

- 13

- Views

- 629