Gravelscratcher

Well-Known Member

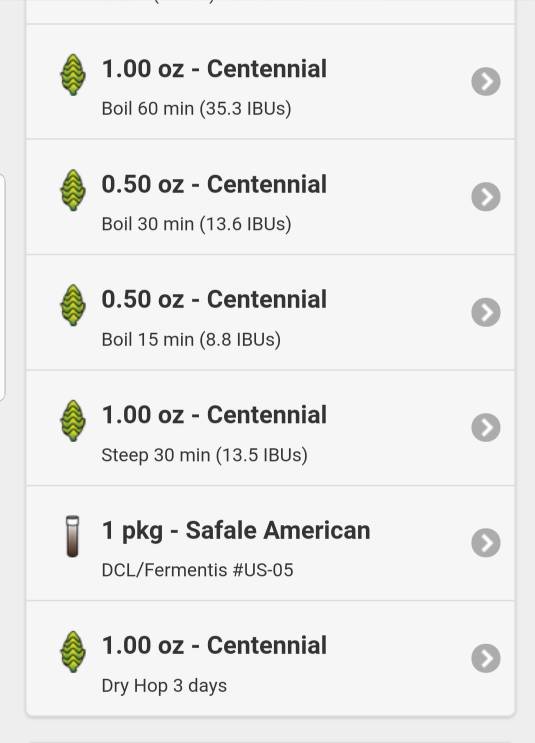

Alright, this is problem I’ve been experiencing with most of my IPA’s...for a long time.

I get a grassy/veggie bitter flavor, with none of the grapefruit, pine, tropical...(the good stuff) from my hops (irrespective of the recipe)...and it doesn’t get better w/ time. All the typical off flavor descriptions (from brewing mistakes) don’t seem to fit what I’m experiencing.

I can brew a stout, and it’s perfect. I can brew a NEiPA with Cryo Hops, and it’s great. I can brew cream ales and steam beers...you get the point.

The minute I try and make an IPA or a Hoppy Pale, with standard pellet hops, I get this grassy vegetable bitter thing.

For the life of me, I can’t figure it out.

I am using a chest freezer and an ink-bird to control my temperature. I’m careful w/ hot side and cold side oxygen. I quit using tap water, and went to buying purified drinking water. I’m ultra clean and sanitized. My mash temp’s are in the 150’s. I bought a new fermenter...and so on.

What sucks is, I love IPA’s and NEIPA’s. I want to make IPA’s, and enjoy some of my favorite beers and experiment with interesting recipe ideas, but all I get is grassy, gross, bitter. They literally all taste the same...doesn’t matter what I do.

I can’t figure it out, and I’m about to only brew w/ Cryo-Hops, because that’s the only real success I’ve had w/ brewing IPAs (the NEIPA I made). It was amazing by the way.

The only thing I haven’t tried, is getting scientific w/ my water and PH levels. But I don’t think that’s the issue here.

Anyway, this is pretty much my last resort. It’s worth my pride to just admit it, if someone can help me figure it out.

I get a grassy/veggie bitter flavor, with none of the grapefruit, pine, tropical...(the good stuff) from my hops (irrespective of the recipe)...and it doesn’t get better w/ time. All the typical off flavor descriptions (from brewing mistakes) don’t seem to fit what I’m experiencing.

I can brew a stout, and it’s perfect. I can brew a NEiPA with Cryo Hops, and it’s great. I can brew cream ales and steam beers...you get the point.

The minute I try and make an IPA or a Hoppy Pale, with standard pellet hops, I get this grassy vegetable bitter thing.

For the life of me, I can’t figure it out.

I am using a chest freezer and an ink-bird to control my temperature. I’m careful w/ hot side and cold side oxygen. I quit using tap water, and went to buying purified drinking water. I’m ultra clean and sanitized. My mash temp’s are in the 150’s. I bought a new fermenter...and so on.

What sucks is, I love IPA’s and NEIPA’s. I want to make IPA’s, and enjoy some of my favorite beers and experiment with interesting recipe ideas, but all I get is grassy, gross, bitter. They literally all taste the same...doesn’t matter what I do.

I can’t figure it out, and I’m about to only brew w/ Cryo-Hops, because that’s the only real success I’ve had w/ brewing IPAs (the NEIPA I made). It was amazing by the way.

The only thing I haven’t tried, is getting scientific w/ my water and PH levels. But I don’t think that’s the issue here.

Anyway, this is pretty much my last resort. It’s worth my pride to just admit it, if someone can help me figure it out.