jseyfert3

Well-Known Member

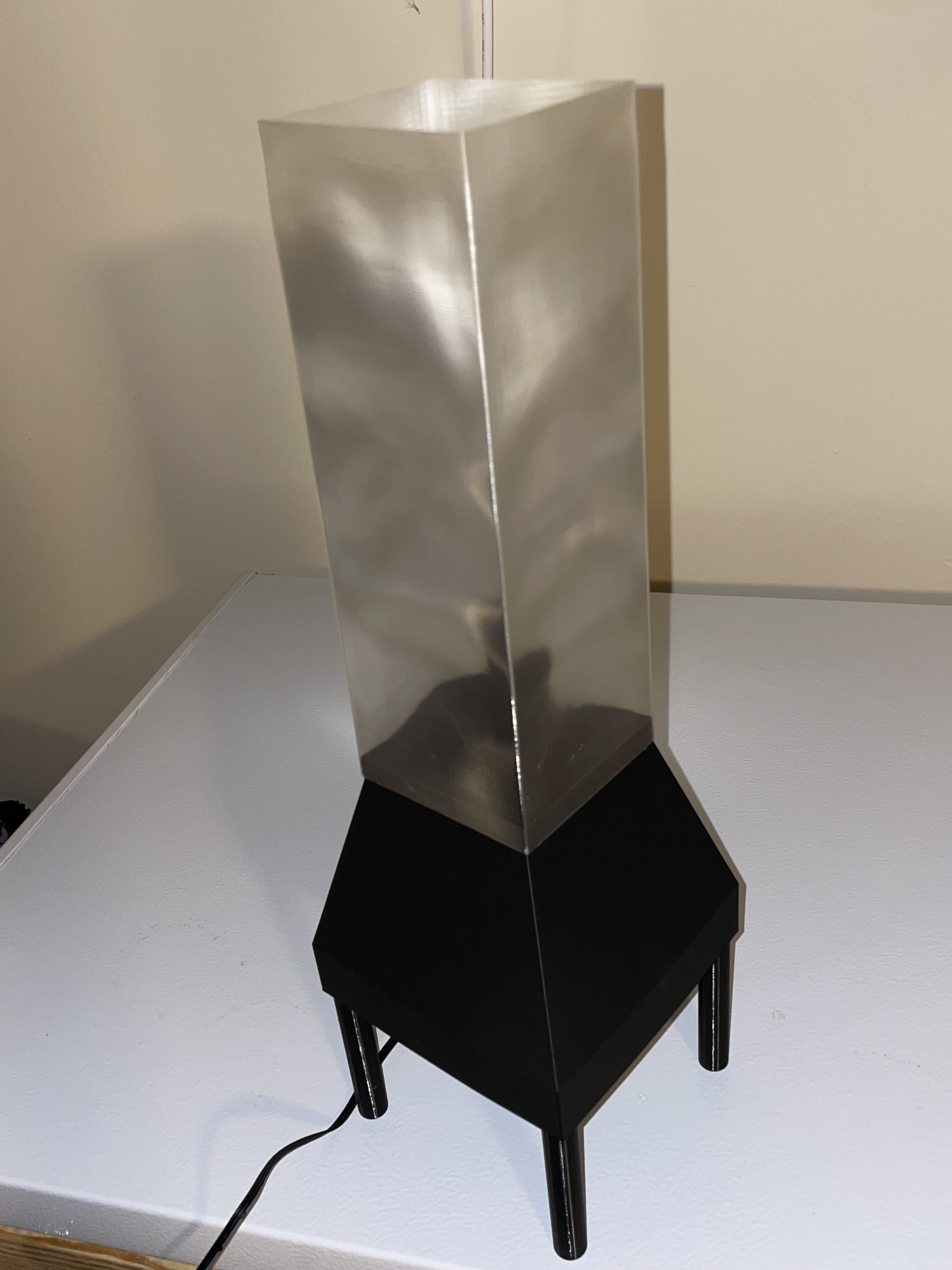

My current kreezer is a Magic Chef 5 cubic foot model. A 2x8 makes up the collar. Recently I added a 1.5 gallon Torpedo keg with an endless carbonation lid. This is plumbed into the RO water, and sits on top of a 5 gallon Torpedo keg. Allows endless carbonated water, and still have three 5 gallon kegs for beer and cider (four taps total).

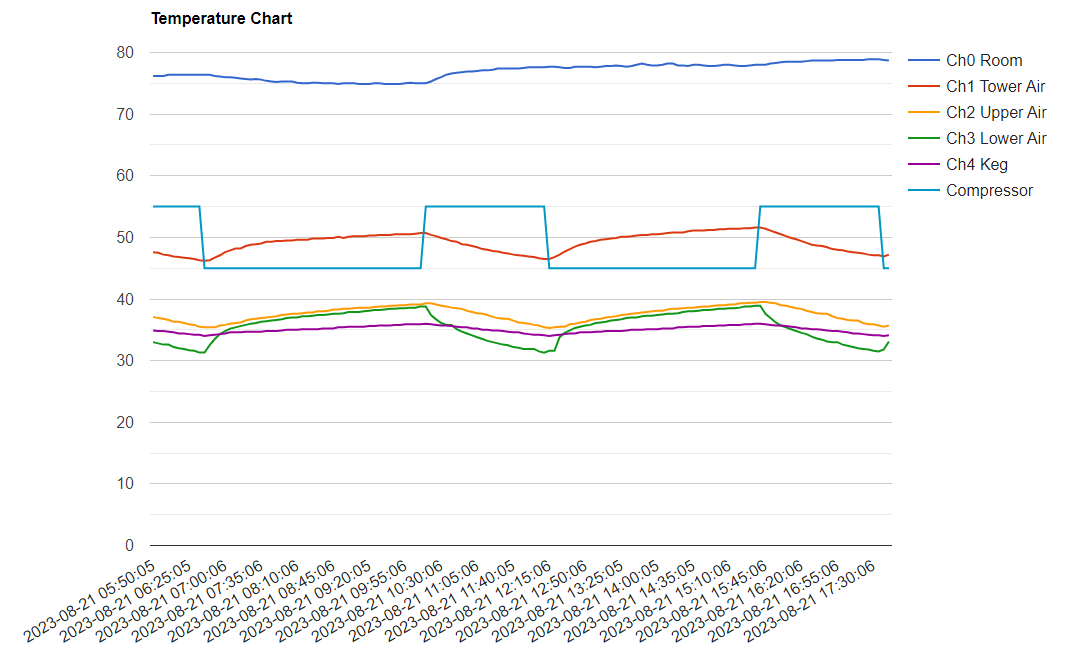

Works great for endless carbonated water. Downside is that now that we aren't pulling water out of a 5 gallon keg, and the 1.5 gallon keg is so high, temp stratification means the water is too warm, and can't carbonate as much as I'd like. Also not as cold as I'd like.

I tried placing a 120 mm computer fan on some legs a few inches off the floor, blowing up between the kegs. The idea/hope was this would push cold air up and cool the 1.5 gallon keg, plus cool the lines for the taps. But it did not. Some quick checks with an IR thermometer showed the inside collar of my kreezer and the 1.5 gallon keg are roughly 50-52 °F after install of fan. IR thermometer showed ~52 °F for water freshly poured into a glass.

Do I need more fans? More powerful fans? This definitely does not seem to be anything close to the world's most powerful computer fan.

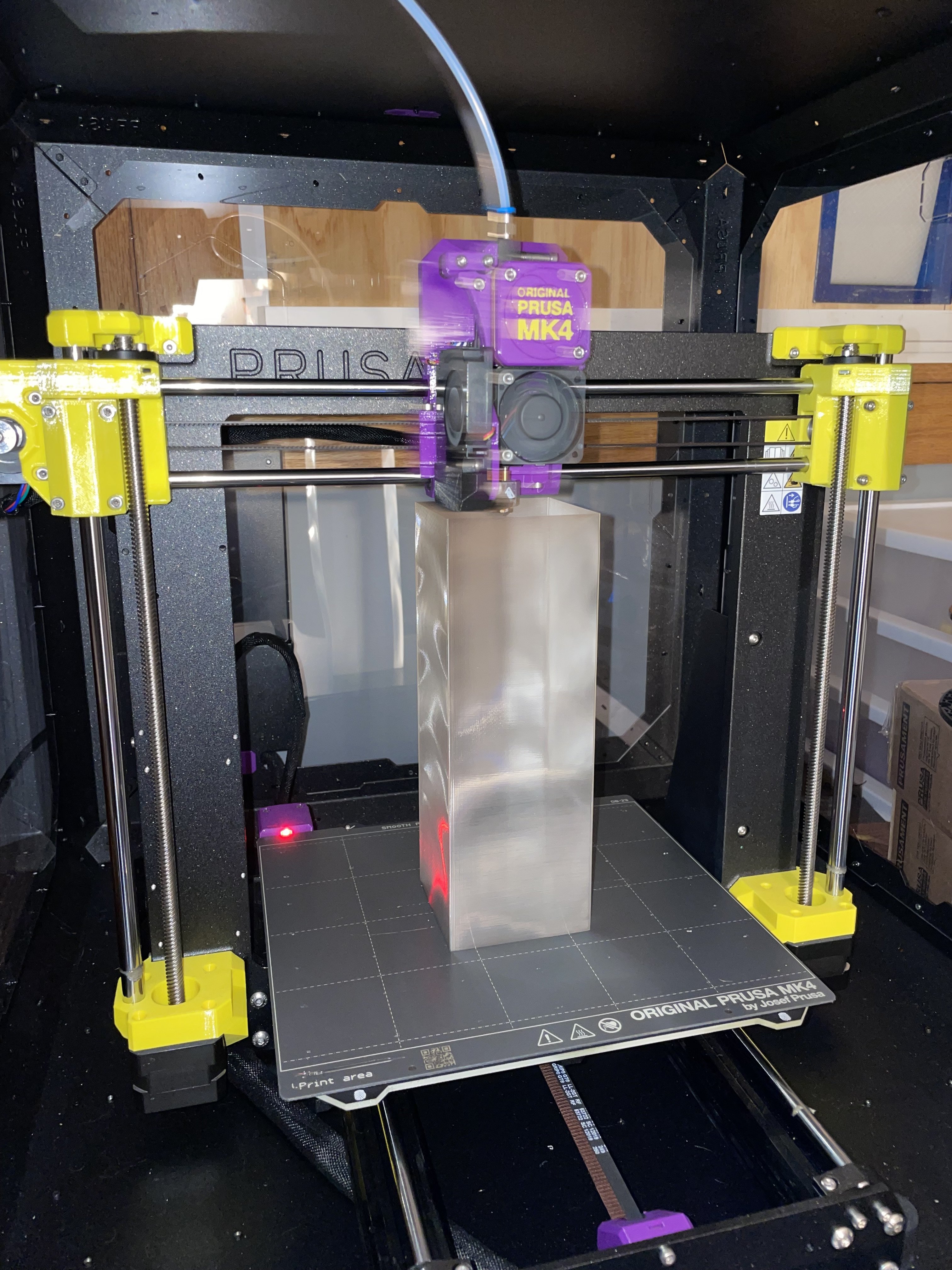

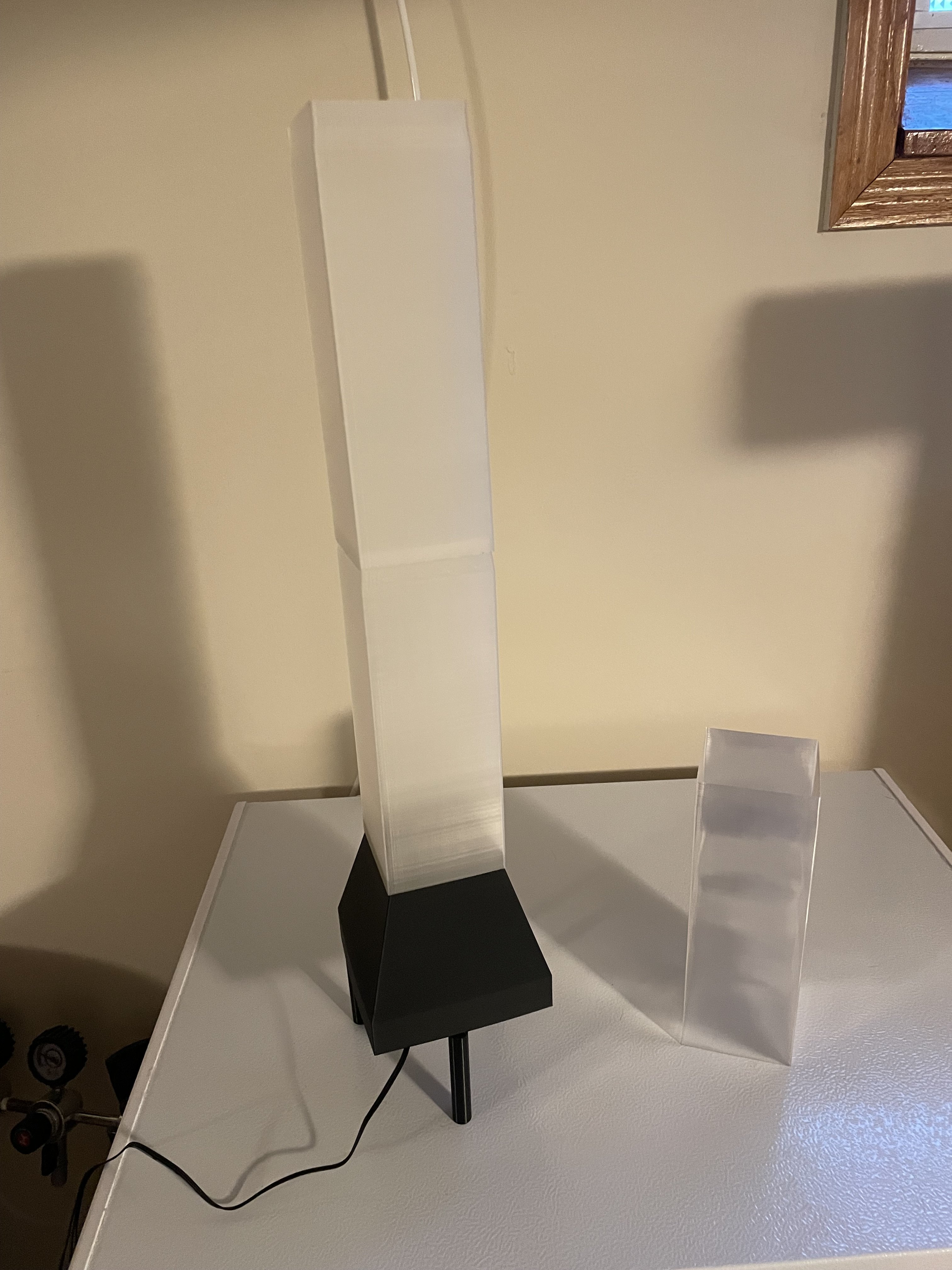

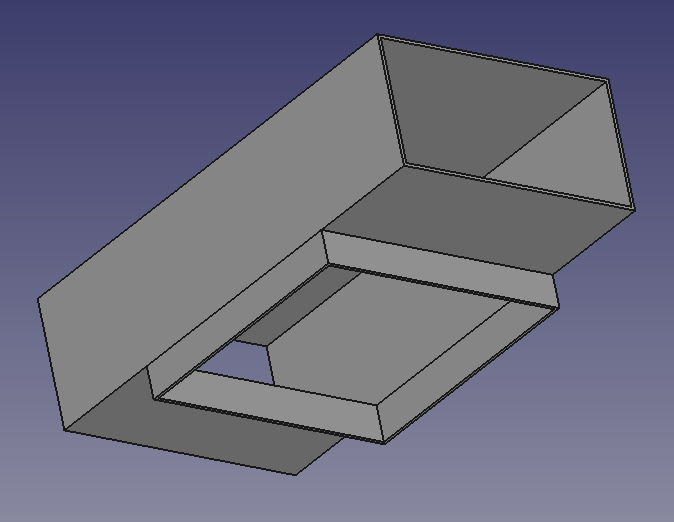

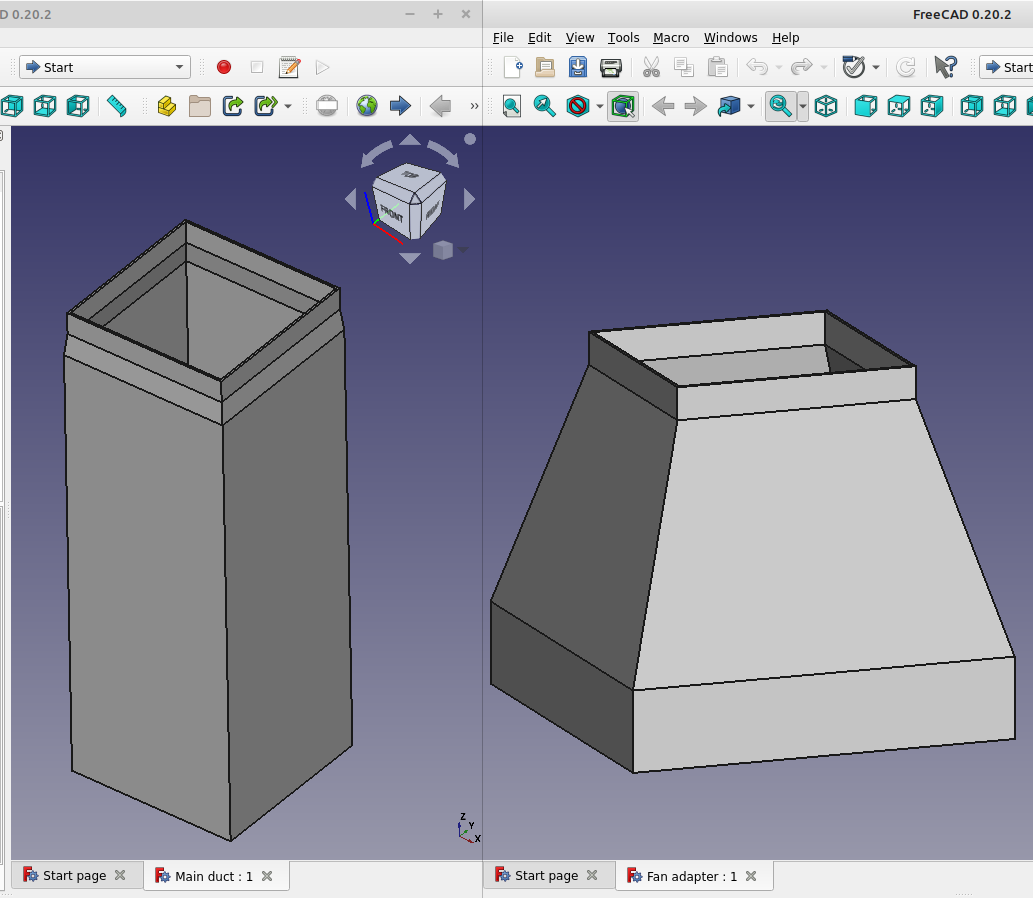

I also own a 3D printer, my thought was printing a duct. Have the fan blow into the duct near the floor of the kreezer, and the top of the duct lets air out at the top of the kreezer.

All thoughts and suggestions welcome. I can get pictures later this evening, if desired.

Works great for endless carbonated water. Downside is that now that we aren't pulling water out of a 5 gallon keg, and the 1.5 gallon keg is so high, temp stratification means the water is too warm, and can't carbonate as much as I'd like. Also not as cold as I'd like.

I tried placing a 120 mm computer fan on some legs a few inches off the floor, blowing up between the kegs. The idea/hope was this would push cold air up and cool the 1.5 gallon keg, plus cool the lines for the taps. But it did not. Some quick checks with an IR thermometer showed the inside collar of my kreezer and the 1.5 gallon keg are roughly 50-52 °F after install of fan. IR thermometer showed ~52 °F for water freshly poured into a glass.

Do I need more fans? More powerful fans? This definitely does not seem to be anything close to the world's most powerful computer fan.

I also own a 3D printer, my thought was printing a duct. Have the fan blow into the duct near the floor of the kreezer, and the top of the duct lets air out at the top of the kreezer.

All thoughts and suggestions welcome. I can get pictures later this evening, if desired.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)