chipwitch

Well-Known Member

Yesterday, I brewed my second true AG. I never liked the idea of using plastic for the mash tun. So, I bought a 15 gallon aluminum pot. I realize that pot is just about the worst possible choice for 5 gallon batches, however, it's given me a unique understanding of the physics of heat/heat loss, etc.

First, the rig. It's a nice heavy aluminum pot about 16" around. I have a 12" domed false bottom and a 1/2" SS valve mounted to the side via SS tubing. The ID of the tubing is the limiting factor, 5/16" iirc. There is an aluminum lid.

The first AG I did with this rig was with a crappy (read: useless) science lab mercury thermometer. I tossed it and bought a thermapen (love it). It is so accurate and quick, you have full confidence in your readings.

Here's what I did to mash. Since aluminum transfers heat so quickly, you need a substantial insulation layer or you need to add heat. I chose the latter as previous experiments with reflectix were a fail. The method was what I'll call GFRIMS (Gravity Fed RIMS). By setting the flame on the lowest setting and controlling flow with the valve, I could heat the mash continuously to account for loss, effectively controlling the temperature. A super fast read thermometer like the thermapen makes this possible. Collecting the wort into a SS pitcher, it could be easily returned to the top of the mash. I held the temperature between 154F and 156F.

For kicks, I tested the mash from above, rather than the stream out of the spigot. What I found is that the mash was 148F. I expected there to be some stratification and the heat would mostly be absorbed beneath the grain bed, but I didn't expect ab 8 degree differential.

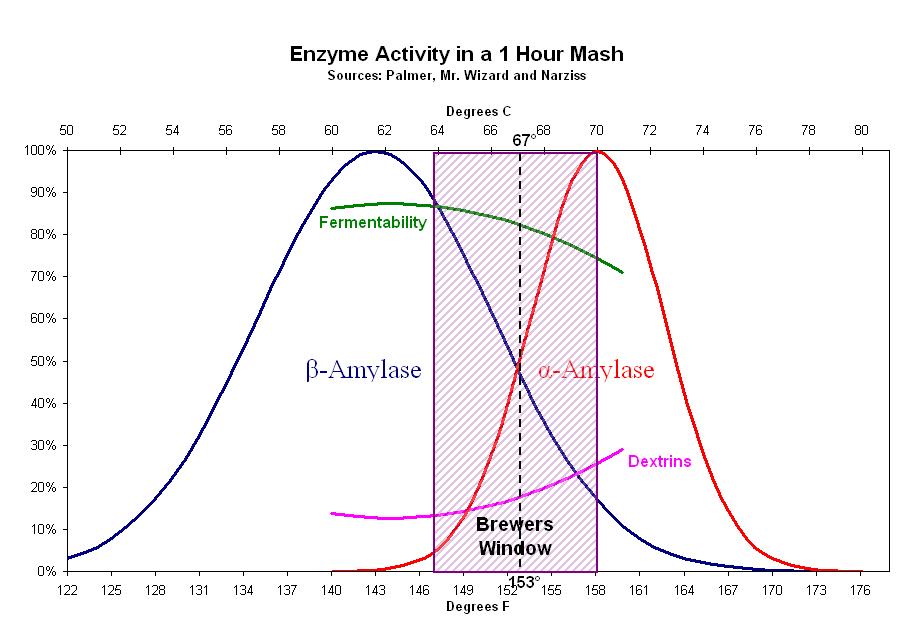

So, that got me thinking about all the talk about the temp you mash at. People talk about mashing to the degree F, when from what I see, it's virtually impossible to keep a uniform temperature throughout. Here is where I imagine the plastic cooler excels, but I'm betting there is still some stratified temperature differential.

So, my question is, "Is the importance of mash temperature, to the 1.0 degree Fahrenheit, overstated?

<edit:> I should mention, I got great conversion. I used braukaiser's spreadsheet for simulating batch sparging. I exceeded the estimated SG's at every step (3 sparge) by about a point.

First, the rig. It's a nice heavy aluminum pot about 16" around. I have a 12" domed false bottom and a 1/2" SS valve mounted to the side via SS tubing. The ID of the tubing is the limiting factor, 5/16" iirc. There is an aluminum lid.

The first AG I did with this rig was with a crappy (read: useless) science lab mercury thermometer. I tossed it and bought a thermapen (love it). It is so accurate and quick, you have full confidence in your readings.

Here's what I did to mash. Since aluminum transfers heat so quickly, you need a substantial insulation layer or you need to add heat. I chose the latter as previous experiments with reflectix were a fail. The method was what I'll call GFRIMS (Gravity Fed RIMS). By setting the flame on the lowest setting and controlling flow with the valve, I could heat the mash continuously to account for loss, effectively controlling the temperature. A super fast read thermometer like the thermapen makes this possible. Collecting the wort into a SS pitcher, it could be easily returned to the top of the mash. I held the temperature between 154F and 156F.

For kicks, I tested the mash from above, rather than the stream out of the spigot. What I found is that the mash was 148F. I expected there to be some stratification and the heat would mostly be absorbed beneath the grain bed, but I didn't expect ab 8 degree differential.

So, that got me thinking about all the talk about the temp you mash at. People talk about mashing to the degree F, when from what I see, it's virtually impossible to keep a uniform temperature throughout. Here is where I imagine the plastic cooler excels, but I'm betting there is still some stratified temperature differential.

So, my question is, "Is the importance of mash temperature, to the 1.0 degree Fahrenheit, overstated?

<edit:> I should mention, I got great conversion. I used braukaiser's spreadsheet for simulating batch sparging. I exceeded the estimated SG's at every step (3 sparge) by about a point.