TandemTails

Well-Known Member

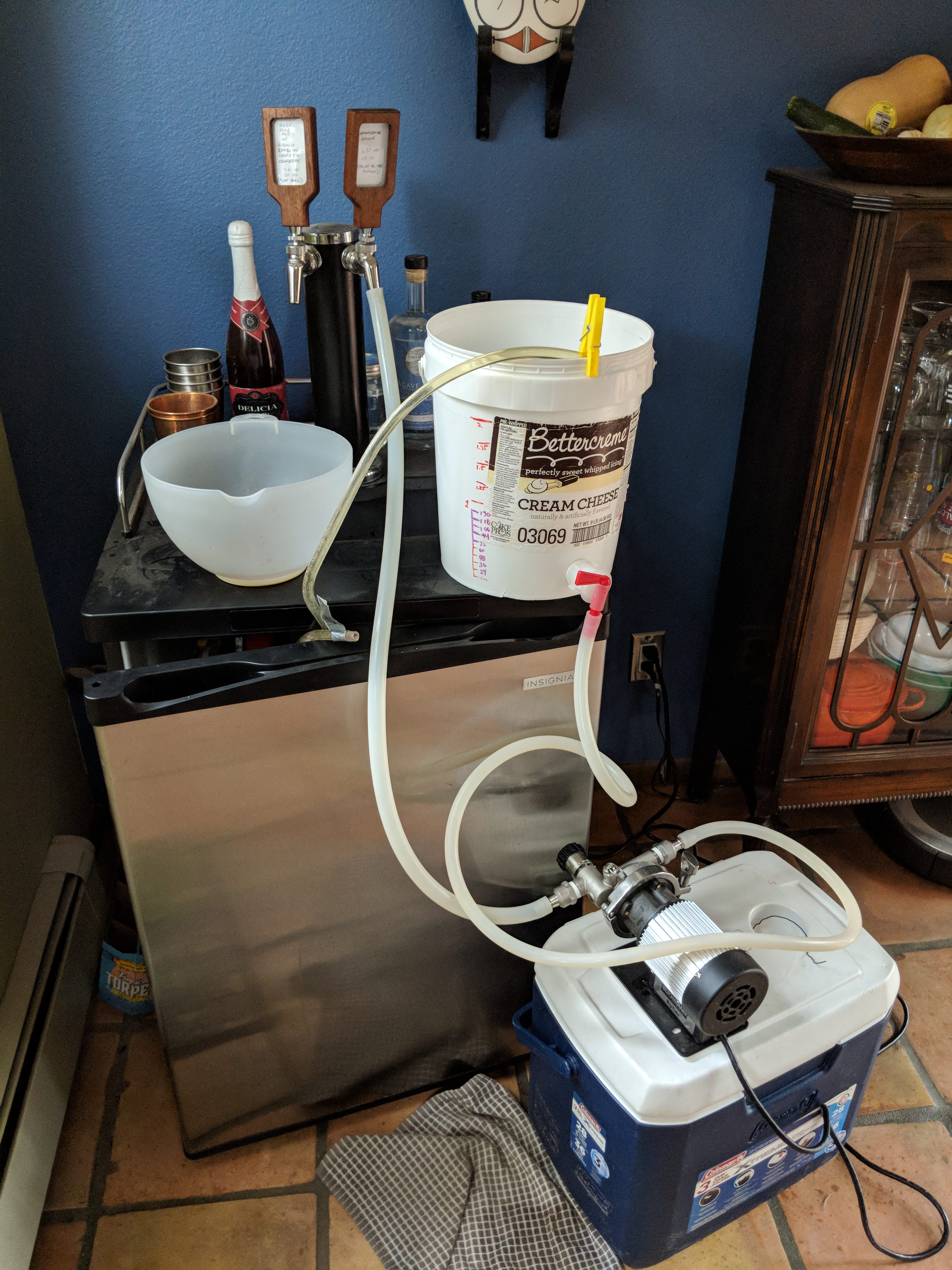

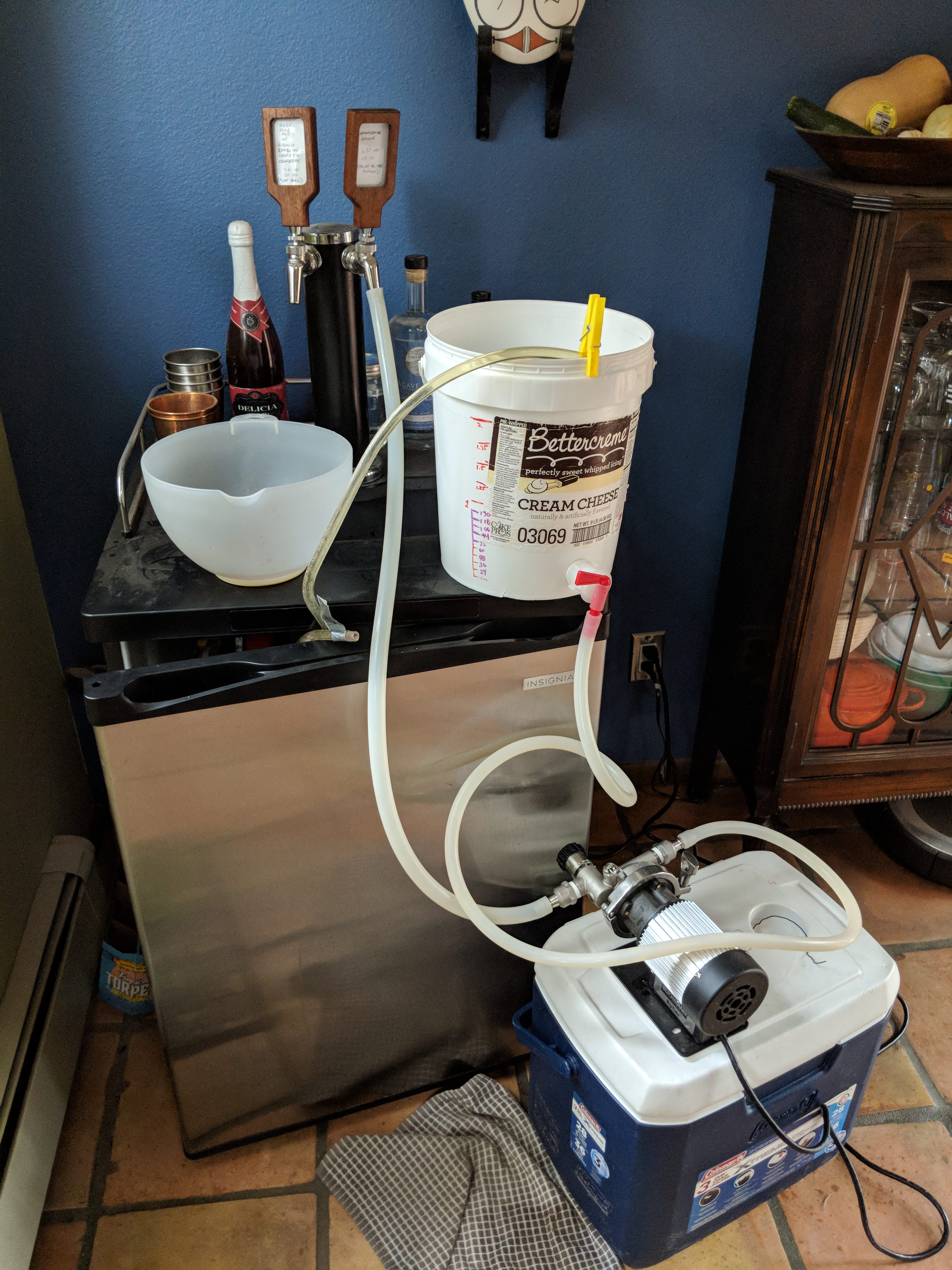

I wanted to find a way to clean my kegerator lines and taps the easiest / laziest way possible so I pulled out my Riptide pump, silicone tubing and small bottling bucket and got to work:

I ran the following cycles backwards through the system (into the tap and out through the beer line)

I'm not sure if I have the timing down. You could simply do one rinse of either PBW or BLC but I wanted to make double sure this line was clean due to lingering ginger ale flavors.

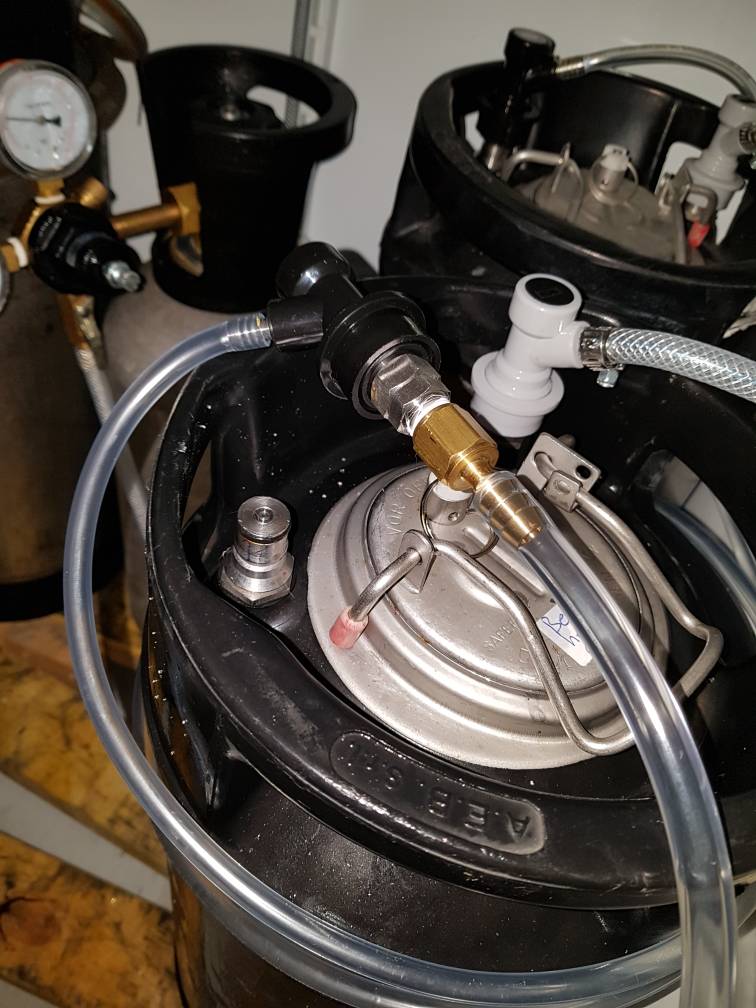

I'll be kegging up a hefeweizen this weekend and will probably do a quick sani rinse through the line from my keg before I fill it with hefe.

I ran the following cycles backwards through the system (into the tap and out through the beer line)

- hot rinse water for a few minutes with the first bit purged into a dump bucket

- hot PBW wash for 15 minutes

- hot water rinse for 10 minutes (with first PBW bit purged into dump bucket)

- BLC wash for 15 minutes (I really wanted to clean this line since i had a ginger ale in here before this keg and could still taste some of it in the beer I had on tap afterwards)

- hot water rinse for 10 minutes

I'm not sure if I have the timing down. You could simply do one rinse of either PBW or BLC but I wanted to make double sure this line was clean due to lingering ginger ale flavors.

I'll be kegging up a hefeweizen this weekend and will probably do a quick sani rinse through the line from my keg before I fill it with hefe.