Brew_G

Well-Known Member

Folks...

I know these questions about high FGs have been asked a million times, but obviously not everyone's situations are the same, so here's an issue I'd like to throw out to the HBT collective for feedback.

Here's my process:

19 days ago: Brewed BIAB brown ale that came out with a higher OG than expected (1.066 v expected 1.062)

5 days ago: Started cold crash

3 days ago: Fined with gelatin and continued crash

1 day ago: Bottled and checked FG at the same time - FG 1.021 (expected was ~1.016)

I foolishly didn't take a gravity reading before cold crashing. That's something I'd normally do, but I was lazy and didn't do it because I figured I'd be just fine letting it ferment out for 14 days. With this strain, I've always been at FG in under a week. I was also dumb in that I continued with bottling after taking that 1.021 reading!

I made a starter of harvested Bell’s yeast a few days prior to brew day, let it crash, then decanted most of the spent wort. Night before brew day, I added about 1L of 1.036 wort and set it back on the stir plate and let it run for about 12 hours, then pulled it from the stir plate and let it sit for a few hours, at which point I pitched it into 66F wort. It was pretty much at high kräusen at that point. I use a 30L Speidel, so I rely on the airlock for indications of fermentation – airlock activity started within 8 hours.

My intent was to hit mash temp of 154F, but I got up to 156F, and it took about 8 minutes of stirring to get it down to 154F (it was hot on my brew day!). That said, I’ve mashed at 157F before with Bell’s yeast and got about 75% attenuation. Edit: That was actually 71% attenuation.

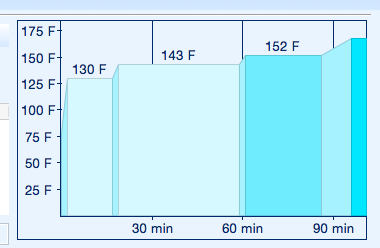

Fermentation took place at 68-69F. At day 4 of fermentation, I bumped the temp to 70F, then raised it by 1-2F every 12 hours, up to 76F, where it stayed for about 5-6 days. No signs of active fermentation at that point. I then proceeded with my cold crash.

Now…this is yeast that I split out from a starter about 5-6 months ago and has been sitting in jelly jars in my fridge ever since. I’m wondering if this could be the reason for the low attenuation. Is that possible, even though the starter fermented nicely and I pitched a healthy amount of yeast at (close to) high kräusen? I generally get 77% attenuation with this strain (give or take a couple percentage points), so the 67% I got on this obviously seems funky.

I’m pretty nervous that I got hasty and bottled this one waaaaay too early, so hopefully I can make any necessary adjustments based on feedback I get from you folks!

TL;DR: I bottled at 1.021 after 14 days of fermentation at proper temps. Did I 'eff up?

I know these questions about high FGs have been asked a million times, but obviously not everyone's situations are the same, so here's an issue I'd like to throw out to the HBT collective for feedback.

Here's my process:

19 days ago: Brewed BIAB brown ale that came out with a higher OG than expected (1.066 v expected 1.062)

5 days ago: Started cold crash

3 days ago: Fined with gelatin and continued crash

1 day ago: Bottled and checked FG at the same time - FG 1.021 (expected was ~1.016)

I foolishly didn't take a gravity reading before cold crashing. That's something I'd normally do, but I was lazy and didn't do it because I figured I'd be just fine letting it ferment out for 14 days. With this strain, I've always been at FG in under a week. I was also dumb in that I continued with bottling after taking that 1.021 reading!

I made a starter of harvested Bell’s yeast a few days prior to brew day, let it crash, then decanted most of the spent wort. Night before brew day, I added about 1L of 1.036 wort and set it back on the stir plate and let it run for about 12 hours, then pulled it from the stir plate and let it sit for a few hours, at which point I pitched it into 66F wort. It was pretty much at high kräusen at that point. I use a 30L Speidel, so I rely on the airlock for indications of fermentation – airlock activity started within 8 hours.

My intent was to hit mash temp of 154F, but I got up to 156F, and it took about 8 minutes of stirring to get it down to 154F (it was hot on my brew day!). That said, I’ve mashed at 157F before with Bell’s yeast and got about 75% attenuation. Edit: That was actually 71% attenuation.

Fermentation took place at 68-69F. At day 4 of fermentation, I bumped the temp to 70F, then raised it by 1-2F every 12 hours, up to 76F, where it stayed for about 5-6 days. No signs of active fermentation at that point. I then proceeded with my cold crash.

Now…this is yeast that I split out from a starter about 5-6 months ago and has been sitting in jelly jars in my fridge ever since. I’m wondering if this could be the reason for the low attenuation. Is that possible, even though the starter fermented nicely and I pitched a healthy amount of yeast at (close to) high kräusen? I generally get 77% attenuation with this strain (give or take a couple percentage points), so the 67% I got on this obviously seems funky.

I’m pretty nervous that I got hasty and bottled this one waaaaay too early, so hopefully I can make any necessary adjustments based on feedback I get from you folks!

TL;DR: I bottled at 1.021 after 14 days of fermentation at proper temps. Did I 'eff up?