OneHoppyGuy

Well-Known Member

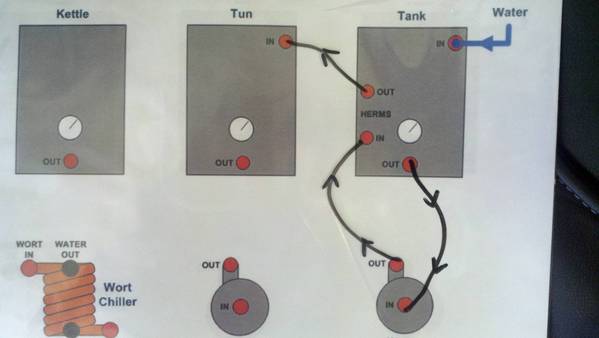

I need help understanding the sparge portion of a HERMS setup.

If the wort is being kept at temperature with a coil in the HLT, when it's time to sparge, where does the 180 degree rinse water come from?

What am I missing

If the wort is being kept at temperature with a coil in the HLT, when it's time to sparge, where does the 180 degree rinse water come from?

What am I missing