I have been struggling to make a pickup tube that works in my keggle. No matter what I do I can't get it to siphon once the water gets below the coupling. I have checked and rechecked everthing for leaks. I have tried teflon tape on the threads and made 2 different types. The first one used a copper tube into a compression fitting and the second was a copper tube soldered into a male thread adapter that screwed into the coupling. Any suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with keggle pickup tube

- Thread starter AleHole

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lil' Sparky

Cowboys EAC

Ummm. You are testing it with a hose attached to your keggle, lowering the effective exit point? If not, then the siphon will stop when the water reaches the valve.

Right, good point. You must have some tubing hanging down to pull the siphon. The weight of the water in the tube pulls a vaccum inside the dip tube to suck the water uphill basically.

I feel like a JACKASS! Thanks for pointing out the obvious. You would think that with all the siphoning I have done that it might occur to me that the oulet needs to be lower than the inlet. What an idiot. Oh well. At least I know how to make pickup tubes really good now and have a few spares.

Thanks for the help and please excuse my ignorance.

Thanks for the help and please excuse my ignorance.

Lil' Sparky

Cowboys EAC

I only knew because at some time I did the same thing.

sfinger

Active Member

Could anyone suggest a good sticky or diagram that would show how to construct the dip tube/pickup tube for a half barrel keggle?

Thanks much....

Thanks much....

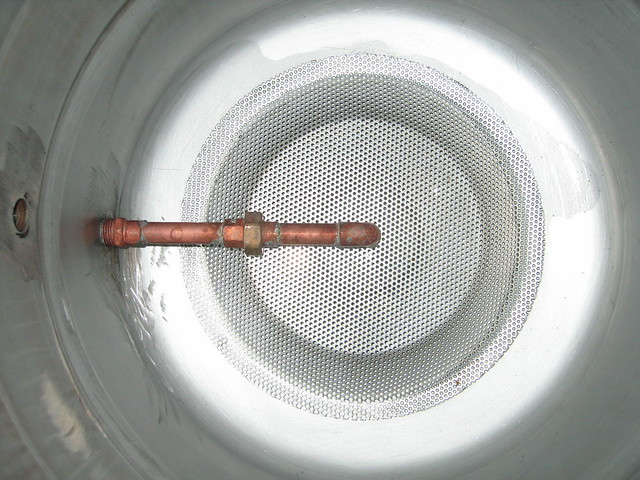

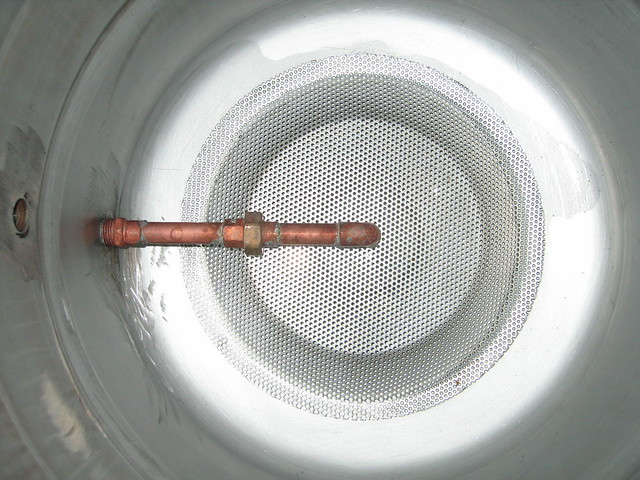

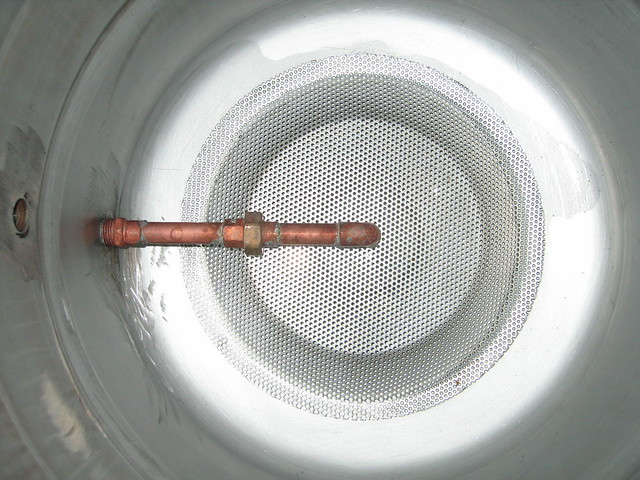

Here's a couple of pics of the one I made. The fitting in the middle is a pipe union which permits quick and easy installation and removal. I usually only remove the half holding down the false bottom. This was made using 1/2" rigid copper pipe:

The port on the converted keg is a 1/2" NPT SS coupling welded flush on the inside. The pickup tube threads directly into the coupling.

The port on the converted keg is a 1/2" NPT SS coupling welded flush on the inside. The pickup tube threads directly into the coupling.

sfinger

Active Member

Here's a couple of pics of the one I made. The fitting in the middle is a pipe union which permits quick and easy installation and removal. I usually only remove the half holding down the false bottom. This was made using 1/2" rigid copper pipe:

The port on the converted keg is a 1/2" NPT SS coupling welded flush on the inside. The pickup tube threads directly into the coupling.

Thanks much for adding this Cat22, it will help a bunch...

Happy to be of some help. A couple of things I forgot to point out on my DIY pickup tube. Look closely on the right side just below the elbow and you will see a "ring" soldered in place there. This "ring" is a section cut from a coupling. The short section of pipe below it passes through the FB, but the "ring" will not. Instead, it pushes down on the FB to hold it in place. If you make a similar pickup tube, you will need to measure and cut the pieces carefully to get it to work properly. I had to enlarge the hole in the FB to fit the hard copper pipe. I used a rotary file bit on a drill to enlarge the hole.

Cpt_Kirks

Well-Known Member

Hey, where did you get the false bottom?

Will it fit through a 12" opening at the top of the keggle?

How effective is it at filtering out trub and hop bits?

Will it fit through a 12" opening at the top of the keggle?

How effective is it at filtering out trub and hop bits?

Hey, where did you get the false bottom?

Will it fit through a 12" opening at the top of the keggle?

How effective is it at filtering out trub and hop bits?

I bought the FB from Northern Brewer: http://www.northernbrewer.com/brewi...arge-hole-false-bottom-1-2-hole-no-elbow.html

The hole is 1/2" dia, but if you want to use hard copper, you will need to enlarge it to 5/8". The 1/2" hole is intended for use with 1/2" OD soft copper or stainless tubing.

Yes, it will fit easily through a 12" opening. I think it's 11" in diameter.

Very effective for filtering hops and trub. I've tried just about everything, and this works best of all so far. I prefer it over the paint strainer thingy by far. Works with pellets or whole hops too. Check out this thread for some pics of how I use it. It's post #16 on page two:

https://www.homebrewtalk.com/f11/whirlpooling-chilling-questions-189401/index2.html

Similar threads

- Replies

- 0

- Views

- 645

- Replies

- 6

- Views

- 1K

- Replies

- 23

- Views

- 1K

- Replies

- 3

- Views

- 700

- Replies

- 2

- Views

- 529