bransona

Well-Known Member

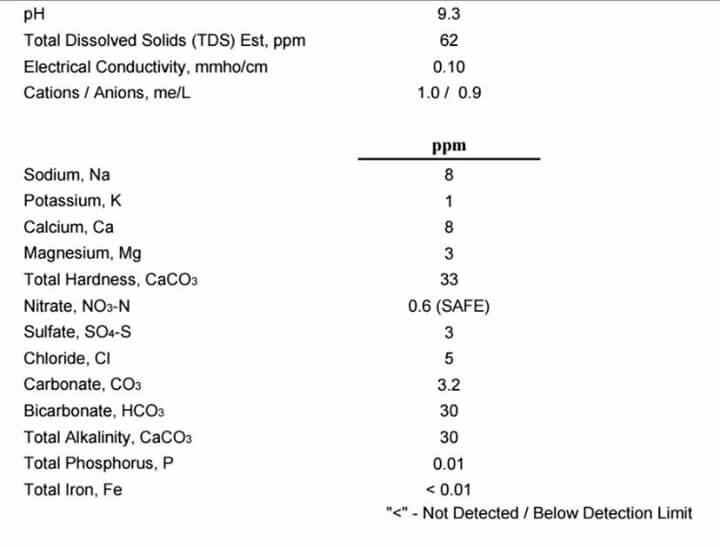

Hi, all. I've been brewing for a few years now, and one common character of my beers has been a general dullness. Not bad or off flavors, just a lack of strong, delicious flavors that I find in commercial brews. I've tweaked a million things and had very little change, from grains to hops to yeast to temps to etc. I had always been told my water was a good start to brew with with no additions.

Well, I ran a recent water report through Bru'n water (because I think I need to finally learn some chemistry), and HOLY CRAP was I way over my expected pH. Bru'n water estimated my typical pale brew mash pH to only be reaching 5.8-6.0. Yikes.

Based on the spreadsheet, I added enough phosphoric acid to hit the 5.41-5.44 area in my first-ever full-volume mash. The beer is now crashing with gelatin and will be kegged tonight, but I'm super anxious.

What did I really change here? What difference will the mash pH make? I hear a lot of talk about it and don't know what to expect! If it goes well, my next step will likely be a sulfate addition since my water has basically no profile beyond alkalinity.

Well, I ran a recent water report through Bru'n water (because I think I need to finally learn some chemistry), and HOLY CRAP was I way over my expected pH. Bru'n water estimated my typical pale brew mash pH to only be reaching 5.8-6.0. Yikes.

Based on the spreadsheet, I added enough phosphoric acid to hit the 5.41-5.44 area in my first-ever full-volume mash. The beer is now crashing with gelatin and will be kegged tonight, but I'm super anxious.

What did I really change here? What difference will the mash pH make? I hear a lot of talk about it and don't know what to expect! If it goes well, my next step will likely be a sulfate addition since my water has basically no profile beyond alkalinity.