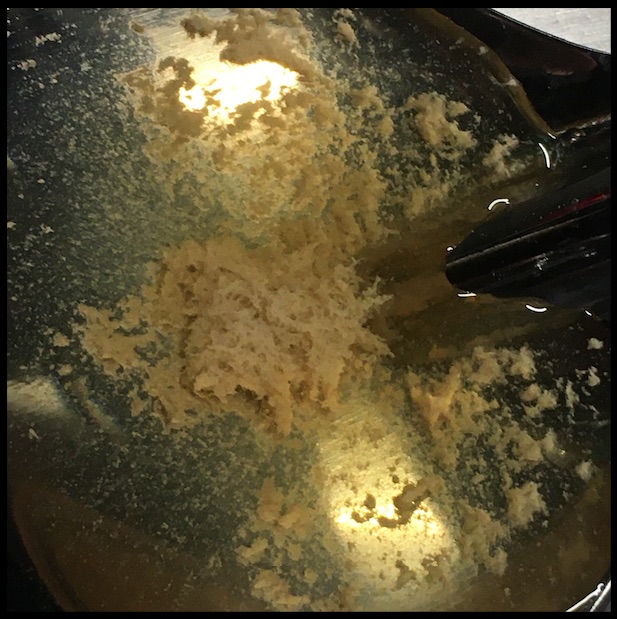

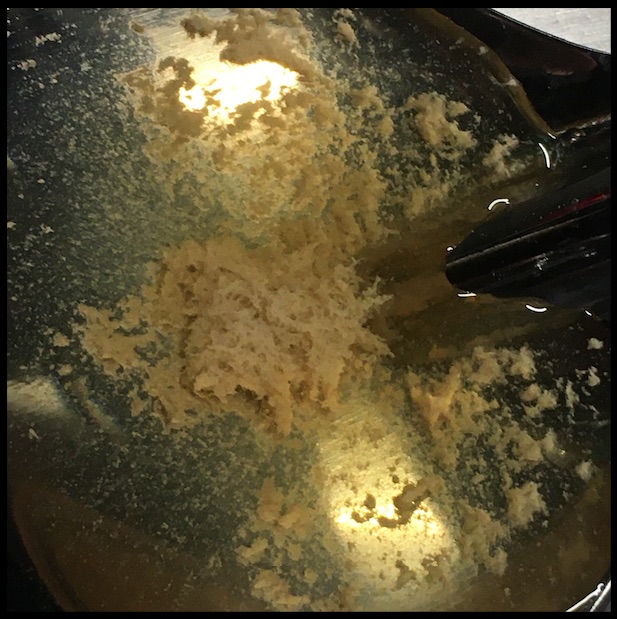

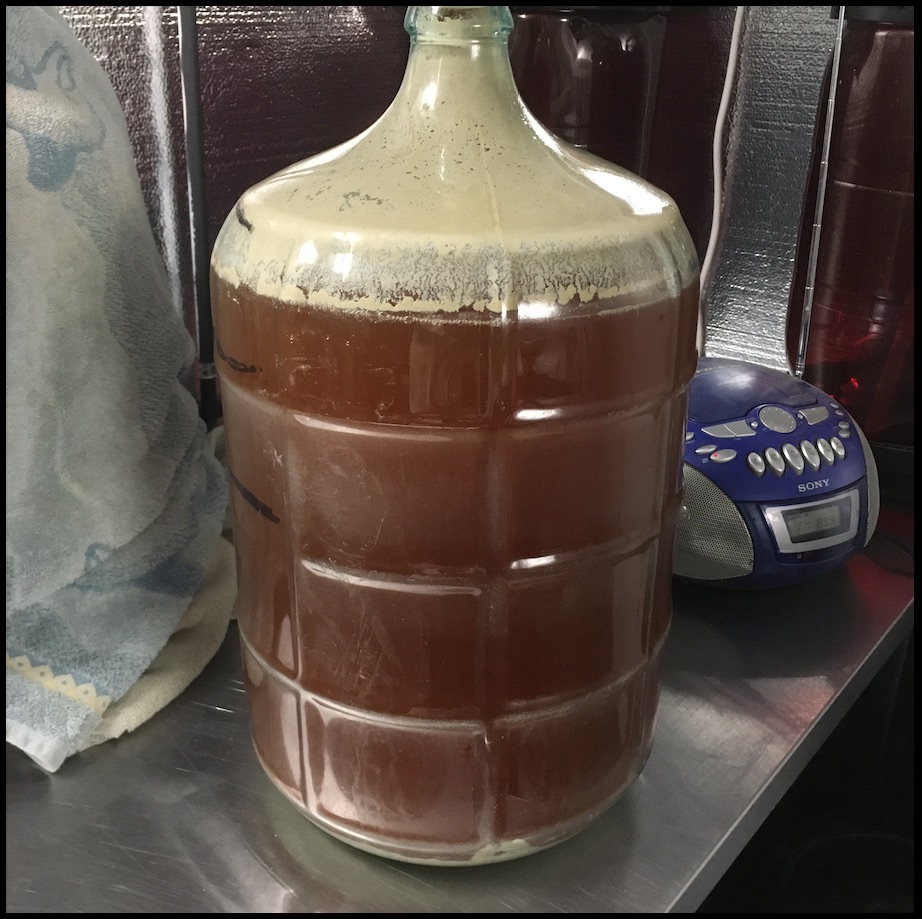

@#p3brews Just a couple tips to add, Ill share my process and equipment, personally I batch sparge but thats not big deal. I do 15gal final batches on a 30gal spike 3 vessel system. With hoppy beers I am for 17.5 gal in the fermenter, for regular ales I aim for 16 gal. This is to make up for losses so I can fill 3 5al corny kegs each time. One recent batch had 38lbs of grain and the total water used was 24ish gal and I typically start with 22gal in the boil kettle to account for boil off, trub loss, and shrinkage from chilling. My mash recirculates for 60 minutes at 150f as a typical target and typically doesn't fluctuate much on the spike system. Then I fly sparge at 170f, this process takes about an hour or so and I typically see an efficiency of 75%-80% depending on the beer, bigger beers get less efficient. As for grain crush you want to make sure your mill is set to the right gap. There are different gaps for each type of grain and this has improved my efficiency greatly. Some typical numbers here are .032 for most barley and .026 for wheat malts. I use beer smith to design my recipes, it has a lot of nice features and if... if you enter your equipment accurately it will get you real close on all your numbers for water volume and temperatures and gravity. You took a huge jump going to 1bbl right off the bat, congratulations on that alone. Getting a system dialed is not an easy task so stick to it and you'll be good in no time. I have had beer from local guys that when they first opened it was not great and a couple months later tried them again and wow, big improvement. Everyone has there own way of doing things so you will come up with your own process along the way, focus on grain crush, mash temp and time, and take your time sparging. Get your water to grain ratio where it needs to be and you should have a decent next brew day.

Cheers!