I am designing a glycol chiller with a 5,000 BTU A/C unit. I would like to have only one pump with two relay temperature controllers (eg a Baylite controller). The first temperature controller will turn on a pump and the A/C unit only to recirculate the glycol until it reaches my set temperature. The second temperature controller will switch a 24 volt solenoid valve (opening it) but then I also want it to switch the single pump on if needed. If the pump is already running in recirculation mode, I don't need to switch it on, just open the valve. If the pump is not running, I need to switch it on along with opening the valve to send glycol to my fermenter. I will be using a manifold. The manifold will always pass the glycol through it (recirculation) when the pump is running but if the output solenoid valve is closed, the fluid will be blocked from going to my fermenter, and if open will be sent fluid to my fermenter.

I understand how to do this if I were to use two separate pumps /circuits, but with this design, I have two inputs that could both be on (one calling for recirculation and the other calling for fermentation temperature control).

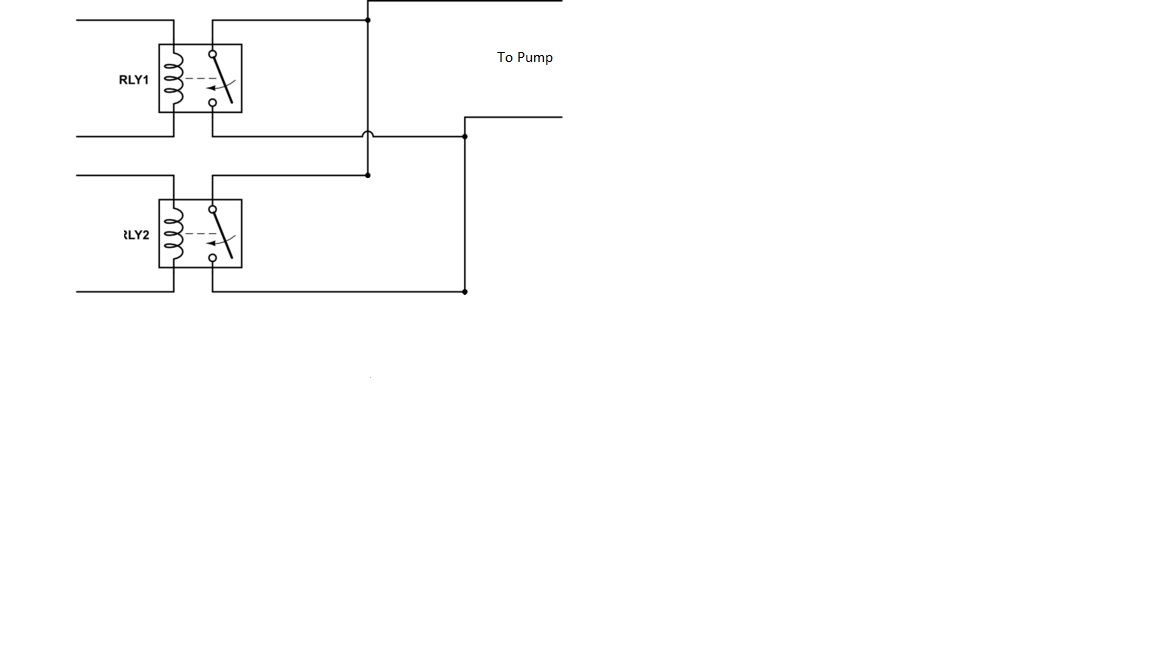

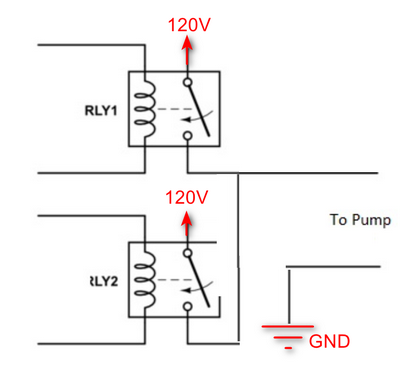

I am trying to figure out if there is some relay that can take two inputs and switch a single load (my pump) if one or both of the inputs are on. Not sure how to do this or I can scrap the idea and go with two pumps with separate circuits, which I understand how to do. Note, I also don't want to keep my pump running all the time.

Any ideas or should I just go to the standard multi-pump design?

I understand how to do this if I were to use two separate pumps /circuits, but with this design, I have two inputs that could both be on (one calling for recirculation and the other calling for fermentation temperature control).

I am trying to figure out if there is some relay that can take two inputs and switch a single load (my pump) if one or both of the inputs are on. Not sure how to do this or I can scrap the idea and go with two pumps with separate circuits, which I understand how to do. Note, I also don't want to keep my pump running all the time.

Any ideas or should I just go to the standard multi-pump design?