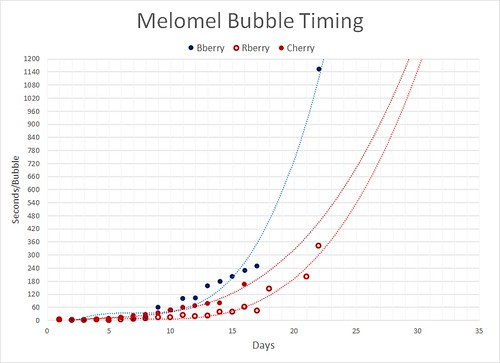

Stephmon

Active Member

- Joined

- Oct 22, 2017

- Messages

- 35

- Reaction score

- 8

Hello formum-ites,

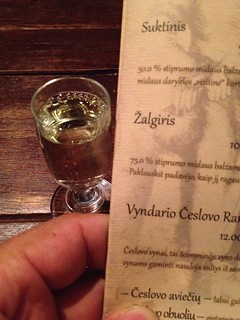

Since I'm new here, I'll introduce myself. I live in NorCal with the Mrs. and our young boys. I was introduced to mead on a business trip to Vilnius, in Lithuania.

Zagares (not to be confused with Zalgaris), Starka (grain vodka), Trejos Devynerios (Bitters made with 27 herbs), Maluniniku (Bitters, Herb Brandy), Krupnikas (spiced honey liqueur)

Žalgiris is sort of infamous there.

"75.0% stiprumo midaus balzamas" translates as 75% strength mead balsam.

As I begin to think about retirement, I started to look into bee keeping as a hobby and making mead seemed a natural extension of that. I'm not ready to set up hives just yet, but when I saw how easy it could be getting started on mead, I decided to give it a try.

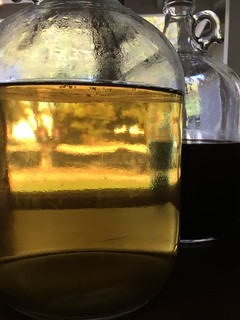

To start, I watched a bunch of YouTube and acquired the essential hardware (4x 1-gallon jugs, airlocks, tubing, yeast, etc.) and made a plan. I started the batches on 9/8 and 9/9 and so far, I've racked once (and snuck a few sips of the melomel, which didn't disappoint). I will be back with updates, observations and questions. Constructive feedback is always welcome.

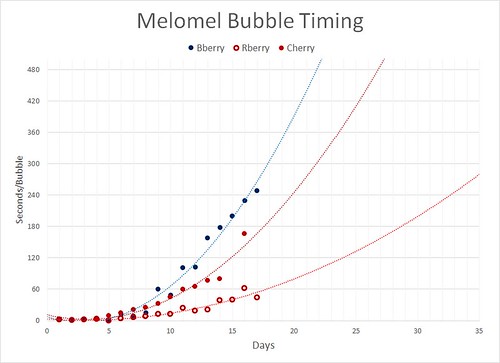

The plan: Two 1-gallon batches. One 'straight' mead and one dark cherry melomel. I figure the melomel will be delicious at just about any point beyond finishing its ferment and I can try it, at various ages, while I take more time with the mead.

The recipes:

Batch 1 (1 Gallon)

Honey Virgin California Wildflower Honey

Amount (honey) 3 lbs

Yeast Red Star Côte des Blancs

Sanitizer Sodium Metabisulphite

Clarifier Bentonite

Yeast Nutrient Yes

Yeast Energizer Yes

Acid Blend Yes

Wine Tannin Yes

Pectic Enzyme Yes (oops, probably unnecessary)

Fruit No

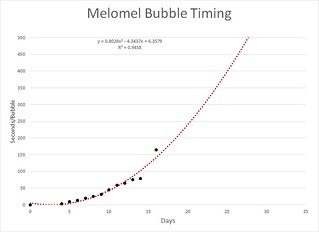

Notes Strong CO2 Bubbles 3/sec after 12 hours

Batch 2 (1 Gallon)

Honey "Virgin California Sage Honey"

Amount (honey) 3 lbs

Yeast Lalvin 71B-1122

Sanitizer Sodium Metabisulphite

Clarifier Bentonite

Yeast Nutrient Yes

Yeast Energizer Yes

Acid Blend Yes

Wine Tannin Yes

Pectic Enzyme Yes

Fruit Dark Sweet Cherries (Whole Foods frozen)

Notes Pre-mixed Bentonite with water for better result. Used juicer, might be better to use blender. 'Cap' knocked down by 'swirling' after one week.

Since I'm new here, I'll introduce myself. I live in NorCal with the Mrs. and our young boys. I was introduced to mead on a business trip to Vilnius, in Lithuania.

Zagares (not to be confused with Zalgaris), Starka (grain vodka), Trejos Devynerios (Bitters made with 27 herbs), Maluniniku (Bitters, Herb Brandy), Krupnikas (spiced honey liqueur)

Žalgiris is sort of infamous there.

"75.0% stiprumo midaus balzamas" translates as 75% strength mead balsam.

As I begin to think about retirement, I started to look into bee keeping as a hobby and making mead seemed a natural extension of that. I'm not ready to set up hives just yet, but when I saw how easy it could be getting started on mead, I decided to give it a try.

To start, I watched a bunch of YouTube and acquired the essential hardware (4x 1-gallon jugs, airlocks, tubing, yeast, etc.) and made a plan. I started the batches on 9/8 and 9/9 and so far, I've racked once (and snuck a few sips of the melomel, which didn't disappoint). I will be back with updates, observations and questions. Constructive feedback is always welcome.

The plan: Two 1-gallon batches. One 'straight' mead and one dark cherry melomel. I figure the melomel will be delicious at just about any point beyond finishing its ferment and I can try it, at various ages, while I take more time with the mead.

The recipes:

Batch 1 (1 Gallon)

Honey Virgin California Wildflower Honey

Amount (honey) 3 lbs

Yeast Red Star Côte des Blancs

Sanitizer Sodium Metabisulphite

Clarifier Bentonite

Yeast Nutrient Yes

Yeast Energizer Yes

Acid Blend Yes

Wine Tannin Yes

Pectic Enzyme Yes (oops, probably unnecessary)

Fruit No

Notes Strong CO2 Bubbles 3/sec after 12 hours

Batch 2 (1 Gallon)

Honey "Virgin California Sage Honey"

Amount (honey) 3 lbs

Yeast Lalvin 71B-1122

Sanitizer Sodium Metabisulphite

Clarifier Bentonite

Yeast Nutrient Yes

Yeast Energizer Yes

Acid Blend Yes

Wine Tannin Yes

Pectic Enzyme Yes

Fruit Dark Sweet Cherries (Whole Foods frozen)

Notes Pre-mixed Bentonite with water for better result. Used juicer, might be better to use blender. 'Cap' knocked down by 'swirling' after one week.