Well if been awhile since ive ran into this issue.

Before using starsan, i used iodophor. I had some bottle contamination issues which i assumed was due to the lack of contact time it had with the iodophor. I switched to using star san to sanitize most of my brewing equipment other than my bottles. The bottles are sterilized in the oven at 350F for an hour.

Ok to the issue. A few months ago I made a Scottish 60 Shilling.

Mashed at 157F

OG 1.036

FG 1.016

Oxygenated and pitched using rehydrated us05.

Sat in primary for 11 weeks before it was bottled, all looked good.

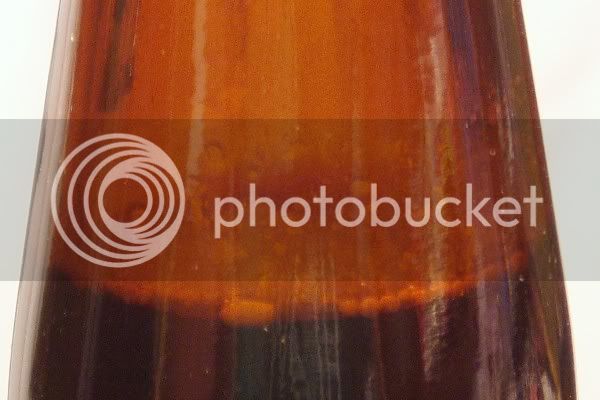

5 weeks in the bottle I noticed the bottles had large white rafts/chunks in the neck of the bottle which fall quickly if the bottles disturbed. There are also large rafts on the bottle of the bottle along with a dusting of "good yeast" All bottles are infected. They are also overcarbonated.

Im unsure of where my issue is coming from, I had this exact contamination issue with a belgian strong as well as a russian imperial stout last year. A common attribute all these beers share is a long primary and/or secondary. I know all objects are clean and sanitized. Is it possible after this long of a primary at room temperature ive lost enough yeast viability that a rouge yeast/bacteria is able to utilize the priming sugar and out compete my original pitching yeast?

Up for some tips/help guys thanks!

Before using starsan, i used iodophor. I had some bottle contamination issues which i assumed was due to the lack of contact time it had with the iodophor. I switched to using star san to sanitize most of my brewing equipment other than my bottles. The bottles are sterilized in the oven at 350F for an hour.

Ok to the issue. A few months ago I made a Scottish 60 Shilling.

Mashed at 157F

OG 1.036

FG 1.016

Oxygenated and pitched using rehydrated us05.

Sat in primary for 11 weeks before it was bottled, all looked good.

5 weeks in the bottle I noticed the bottles had large white rafts/chunks in the neck of the bottle which fall quickly if the bottles disturbed. There are also large rafts on the bottle of the bottle along with a dusting of "good yeast" All bottles are infected. They are also overcarbonated.

Im unsure of where my issue is coming from, I had this exact contamination issue with a belgian strong as well as a russian imperial stout last year. A common attribute all these beers share is a long primary and/or secondary. I know all objects are clean and sanitized. Is it possible after this long of a primary at room temperature ive lost enough yeast viability that a rouge yeast/bacteria is able to utilize the priming sugar and out compete my original pitching yeast?

Up for some tips/help guys thanks!