Turfgrass

Well-Known Member

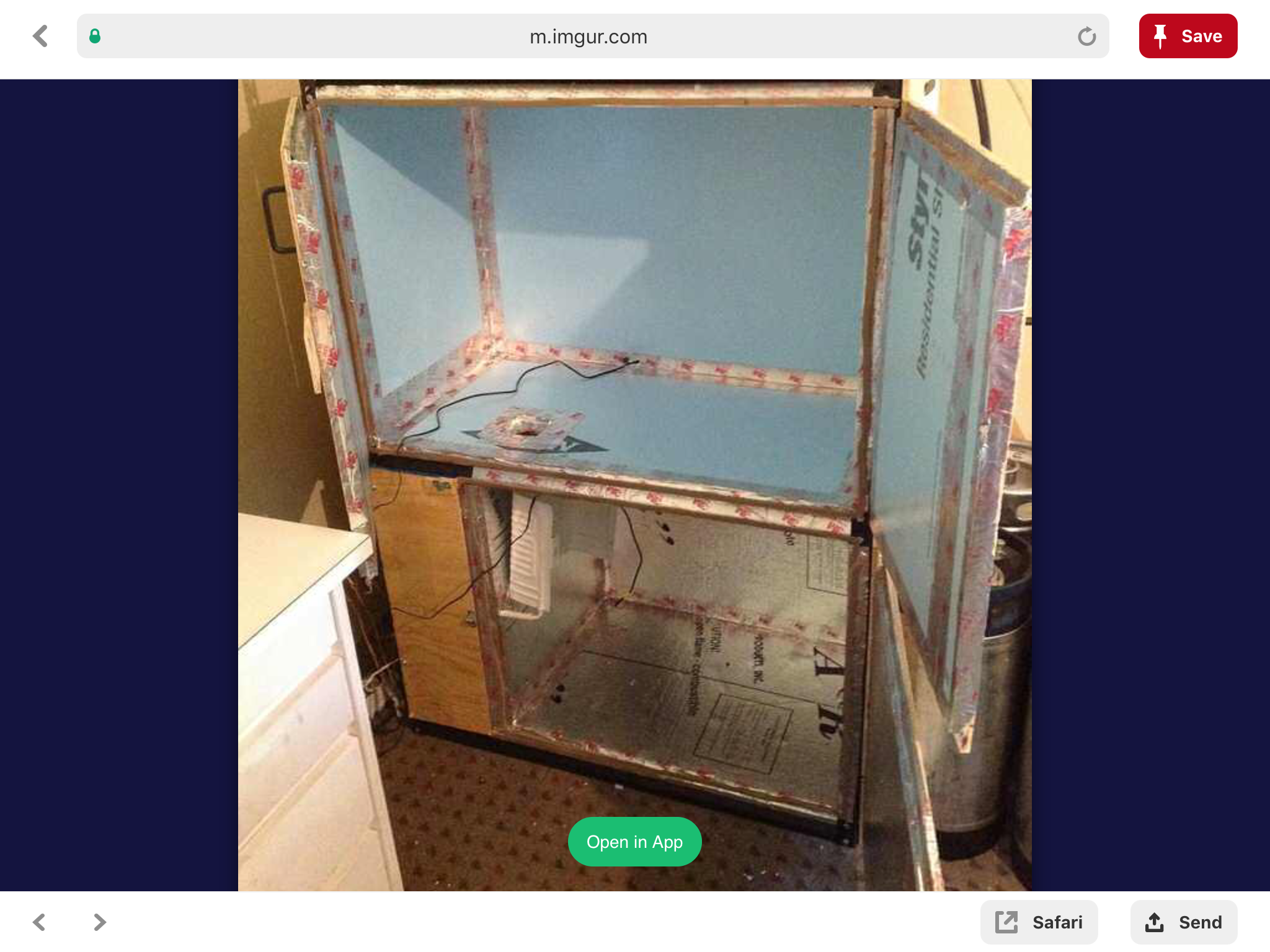

The plan is doing something simple as pictured below, but wondering about the heat source and electrical setup. Cooling won’t be part of the setup.

Right now I’m using the plastic heat wraps (from weekend brewer) that can be taped to my carboys. I want to have 4 brews fermenting at any one time, so two 5 gallon carboys per shelf. The beers will be different, so fermentation temp will change as well, for example, saison versus IPAs and why staying with plastic wraps is preferred. 4 wraps and 4 inkbird controllers.

Anyone have pics they could share of a similar idea or have suggestions on the electrical setup? Thank you.

Right now I’m using the plastic heat wraps (from weekend brewer) that can be taped to my carboys. I want to have 4 brews fermenting at any one time, so two 5 gallon carboys per shelf. The beers will be different, so fermentation temp will change as well, for example, saison versus IPAs and why staying with plastic wraps is preferred. 4 wraps and 4 inkbird controllers.

Anyone have pics they could share of a similar idea or have suggestions on the electrical setup? Thank you.

Last edited: