- Joined

- Jun 29, 2014

- Messages

- 515

- Reaction score

- 50

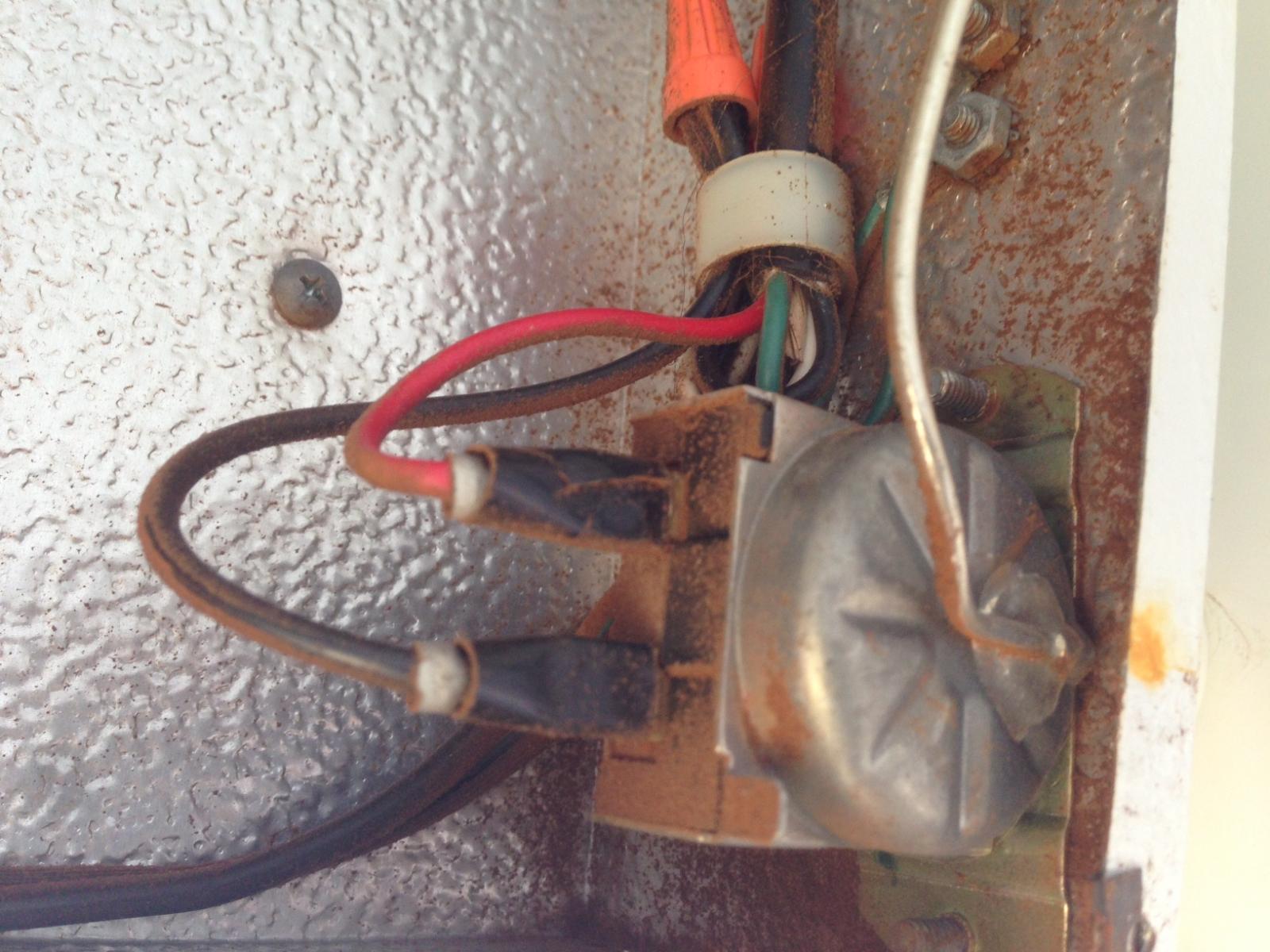

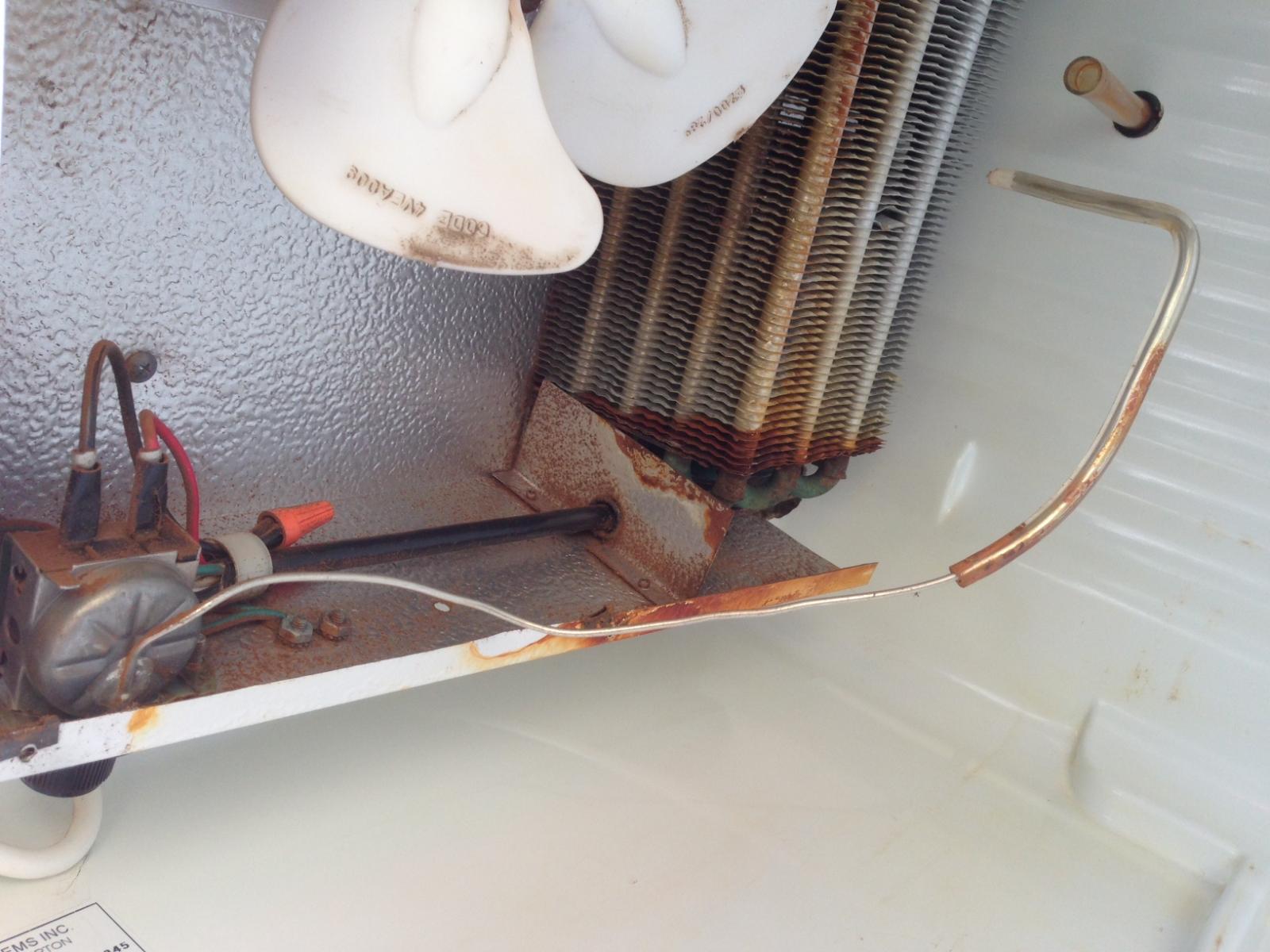

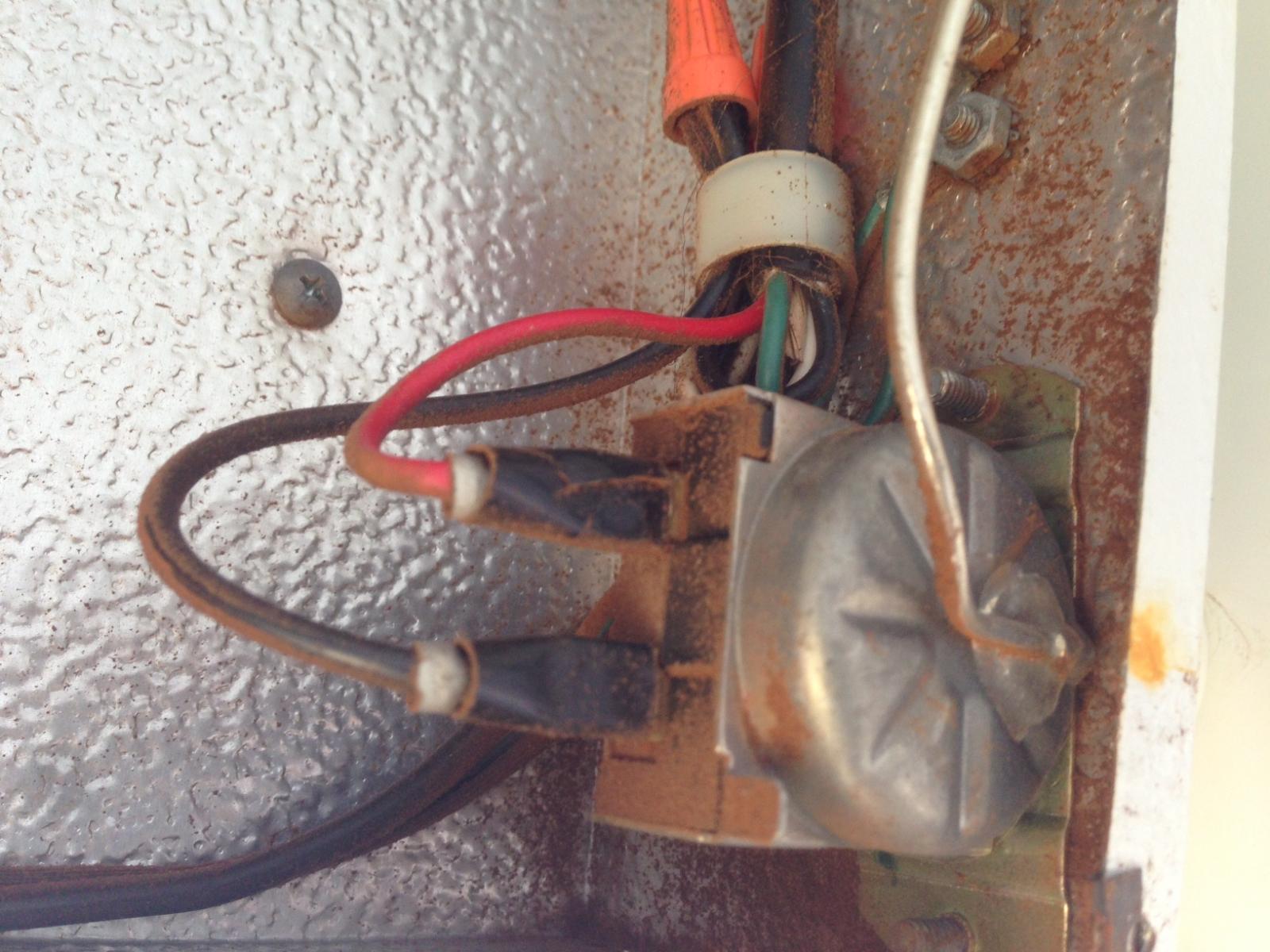

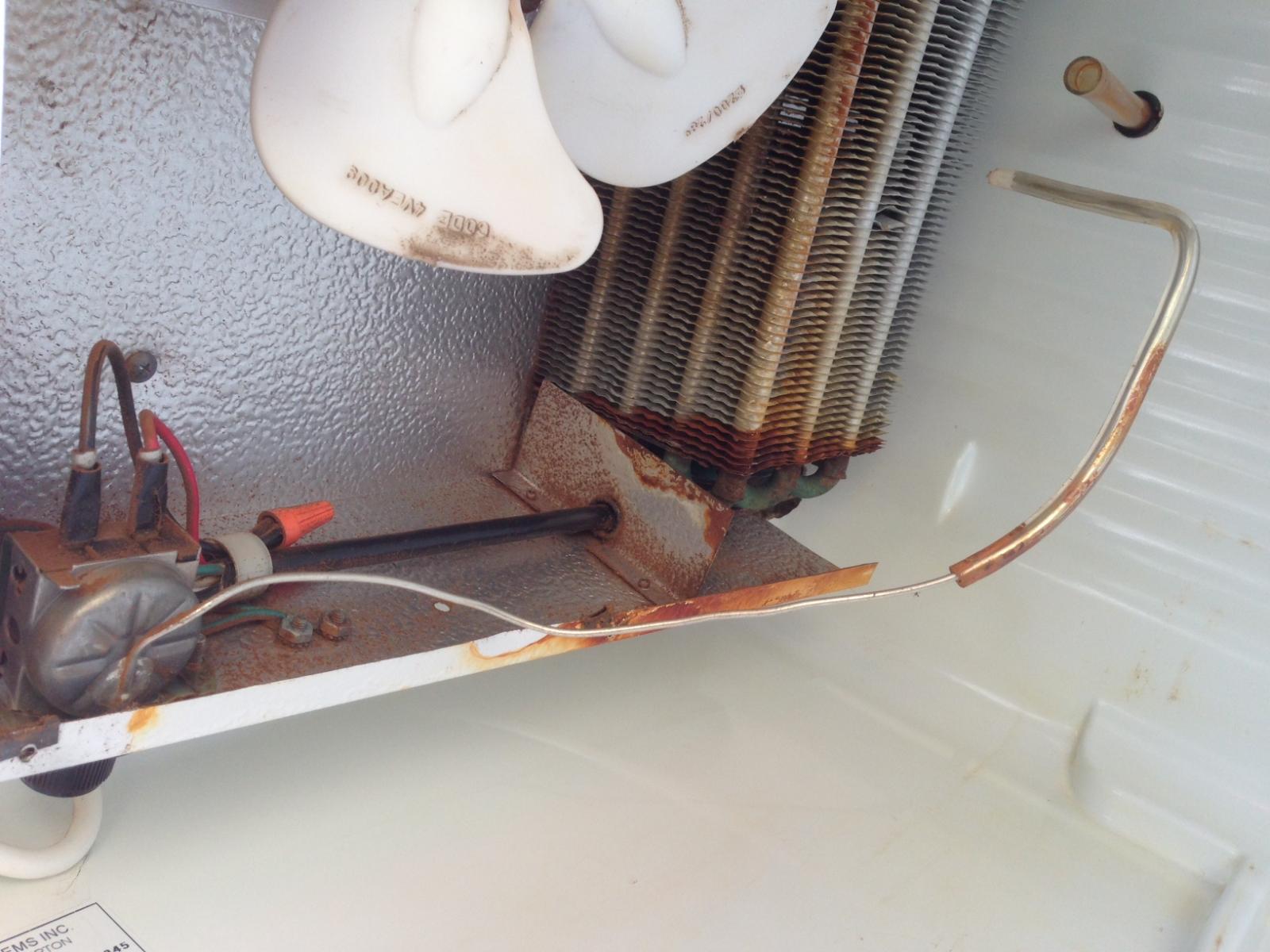

So, I picked up this glass door fridge to be used as a fermentation chamber.

The way I see it I have two simple options for quick temp control.

1. Use the current thermostat and make a note of the ambient air temperature at each position on the dial.

2. It looks like it would be pretty simple to swap out the current thermostat for an STC-1000 but I wanted to ask the experts since I have never done it before.

Ideas?

Thanks,

David

The way I see it I have two simple options for quick temp control.

1. Use the current thermostat and make a note of the ambient air temperature at each position on the dial.

2. It looks like it would be pretty simple to swap out the current thermostat for an STC-1000 but I wanted to ask the experts since I have never done it before.

Ideas?

Thanks,

David