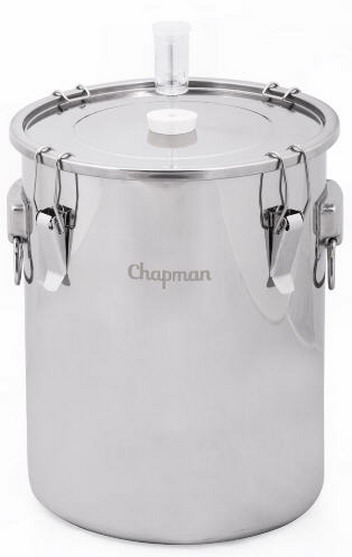

I am looking at Chapman seven and fourteen gallon fermenters to use for closed transfer kegging. Is anyone currently using either size?

Advertised as a seven gallon fermenter having a twelve inch inside diameter and 16 inch height should hold 7.83 gallons. At this point any information about using these fermenters will be helpful.

Advertised as a seven gallon fermenter having a twelve inch inside diameter and 16 inch height should hold 7.83 gallons. At this point any information about using these fermenters will be helpful.