Dustin_J

Well-Known Member

So, the wife and I just moved into a new house (1904 construction, stone foundation), and I am interested in moving the brewing activities indoors into our basement. I currently have a single-tier converted-keg propane-fired stand, a single March 809 pump (I'm a batch sparger), and whirlpool immersion chiller as the basics of the system.

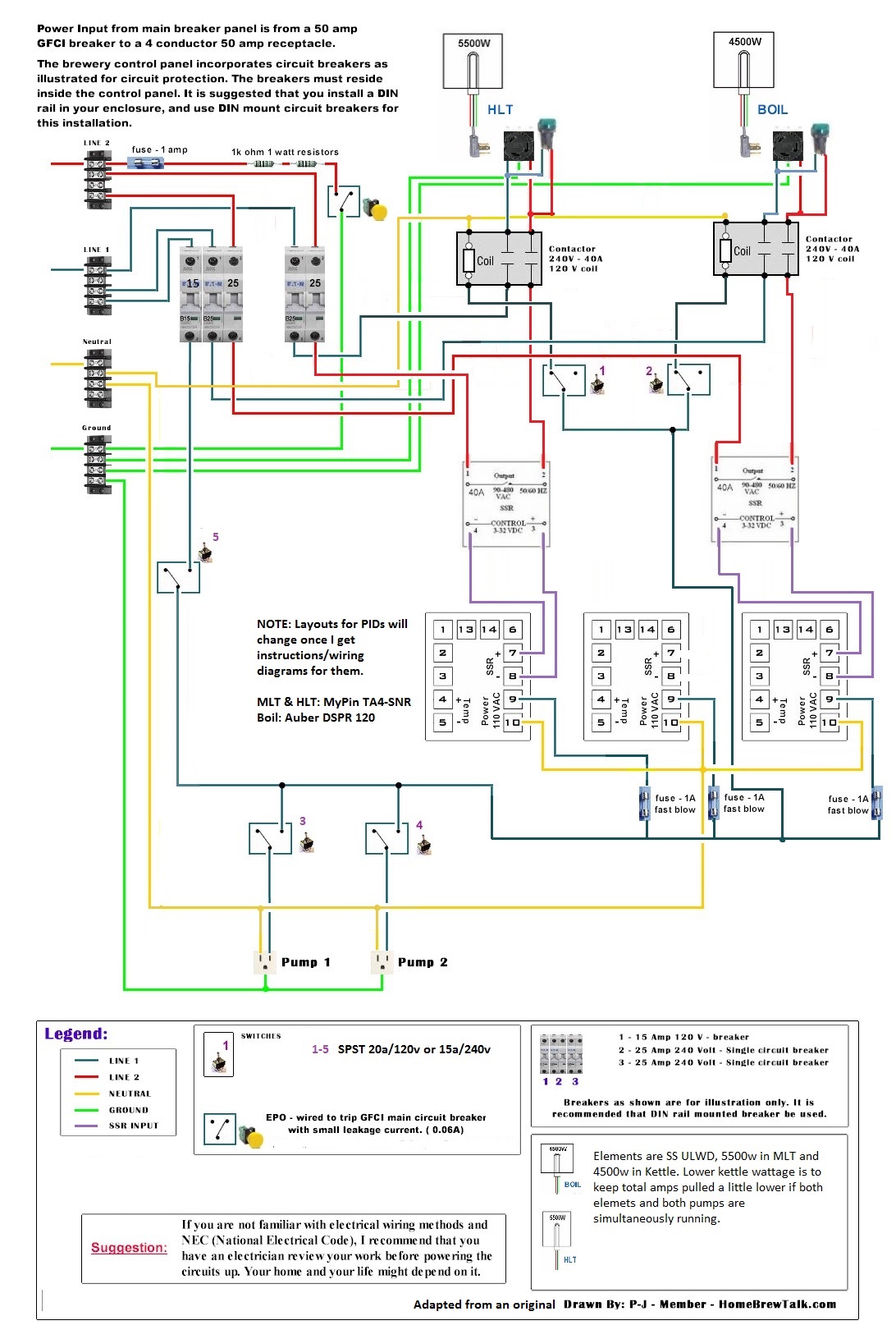

I'd like to go electric, and I'm strongly considering a simple 30a (EDIT: will be doing 50a) HERMS System. The idea would be that I would just convert the existing stand/system by adding elements, a simple control panel, a herms coil in the MLT (I already have plenty of 1/2 copper from a previous chiller bulid), and 1 additional pump.

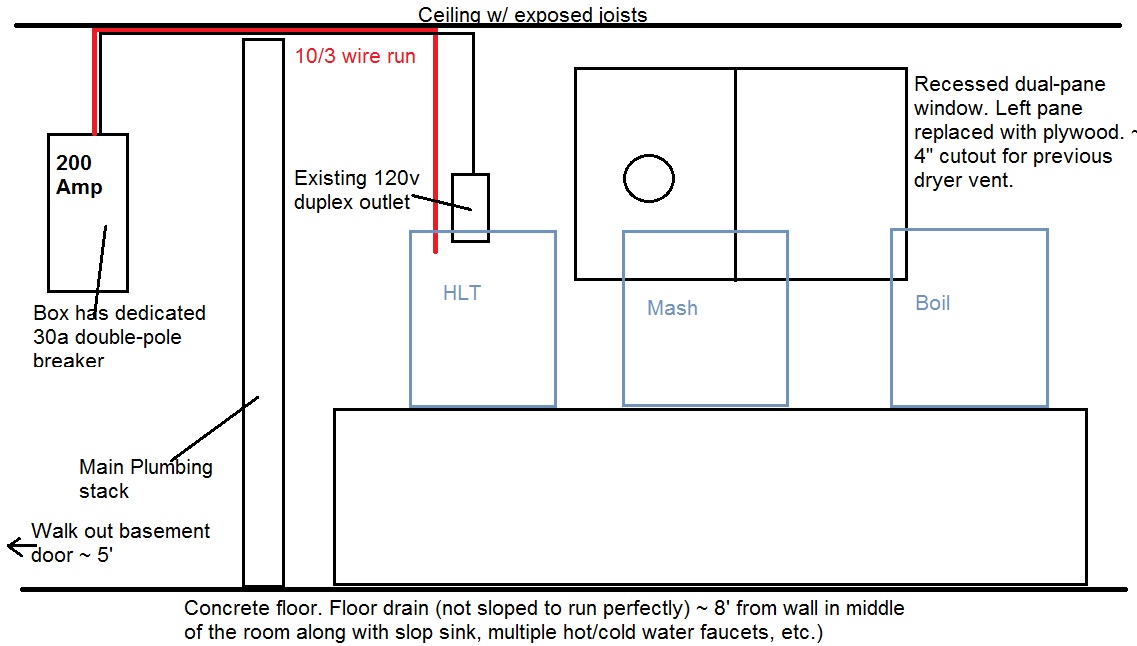

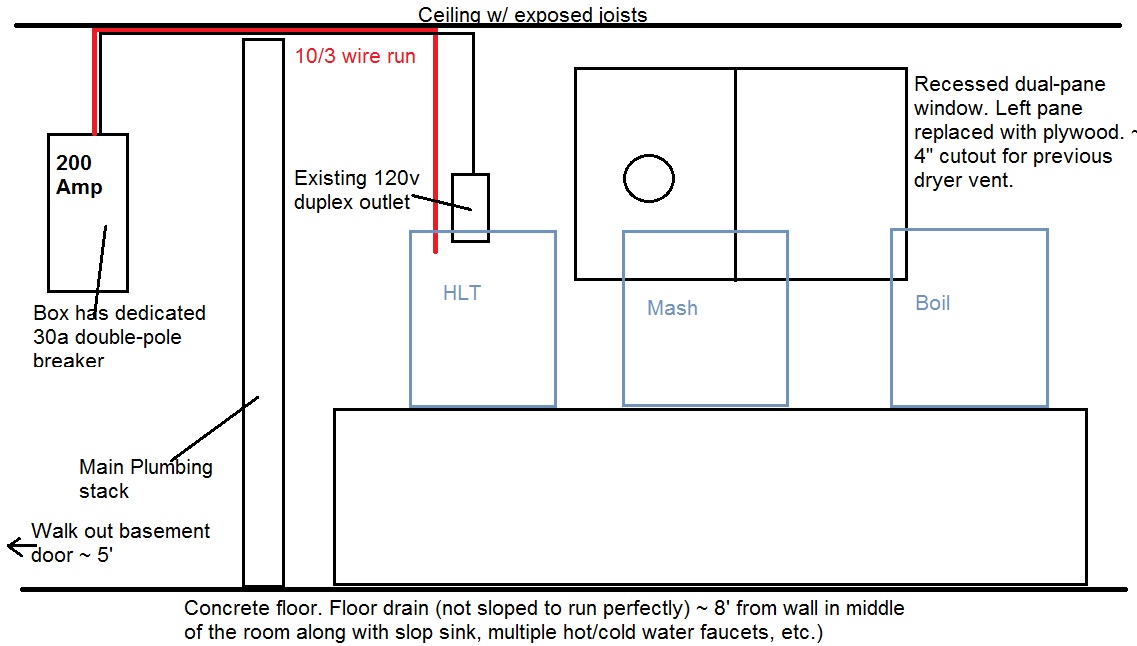

I've attached a diagram of the space (I'll post some pictures later) I'm considering, and a few initial thoughts. Any input/help folks could provide as I move forward with this would be greatly appreciated.

For background, even though I'm using kegs, I'm almost exclusively interested in 5 gal batches and batch sparging.

Rough Illustration

Stand Area

Cleanup/water/drain area

The basics:

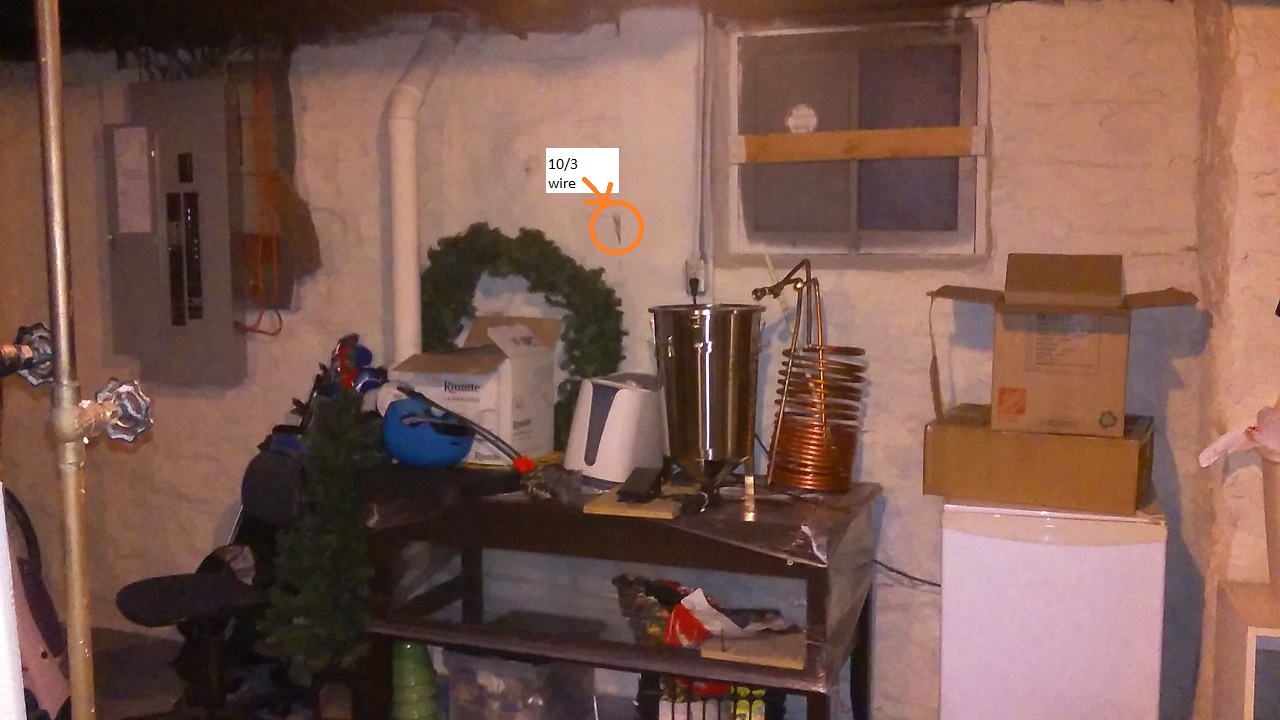

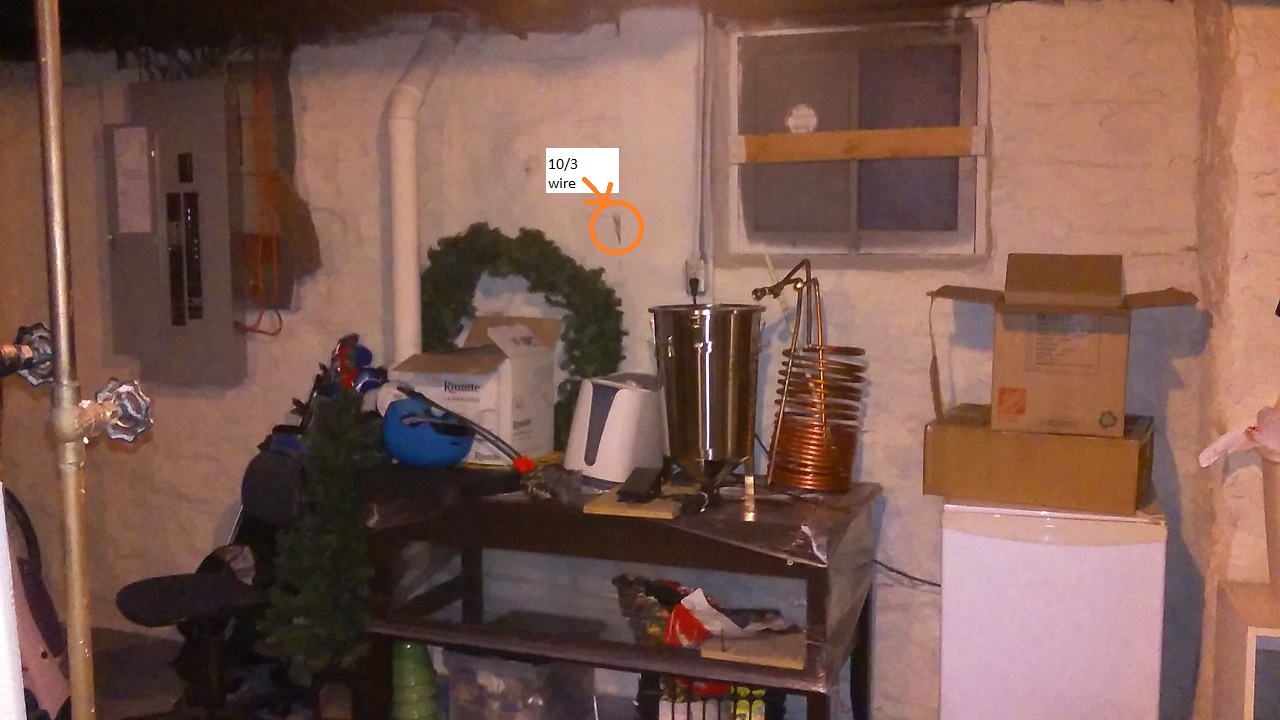

- Electrical: The main electrical box (200 amp service) for the house is nearby. There is an existing, dedicated 30a double-pole breaker in the box with a 10/3 wire run (see diagram), but no plug is installed. Also, no GFCI right now, but I think I'd probably just have a 30a GFCI breaker installed in the box. Also, a 120v outlet on a separate circuit is already wired (but could easily be moved a bit) in the space. (EDIT: will be running 6/4 from the panel with a 50a GFCI breaker.)

- Ventilation: A dryer was apparently installed here at one time. There is an existing 2-pane window (recessed ~ 6 inches), which 1 pane has been changed to plywood with a ~4" hole in place for the dryer vent. This could easily be changed to provide a larger outlet directly outside. Also, the walk-out door for the basement is ~ 5 feet away, which would be easy to crack open to provide replacement air as needed.

- Water/drainage: If you put your back against the wall in the diagram, about 8 feet away (in the middle of the room) is where the washer(s) was previously installed. There is currently a slop sink, multiple operating (and free) hot & cold water faucets, and a floor drain. The slope of the concrete floor doesn't allow for easy drainage (i.e. I can't just slop water everyone and expect it to find the drain), but it is close enough that hoses could easily be ran to it for drainage if I'm careful.

After doing a little research, this seems like a pretty ideal setup other than the lack of really clean drainage. Does anybody see anything glaring that I'm missing here?

I'd like to go electric, and I'm strongly considering a simple 30a (EDIT: will be doing 50a) HERMS System. The idea would be that I would just convert the existing stand/system by adding elements, a simple control panel, a herms coil in the MLT (I already have plenty of 1/2 copper from a previous chiller bulid), and 1 additional pump.

I've attached a diagram of the space (I'll post some pictures later) I'm considering, and a few initial thoughts. Any input/help folks could provide as I move forward with this would be greatly appreciated.

For background, even though I'm using kegs, I'm almost exclusively interested in 5 gal batches and batch sparging.

Rough Illustration

Stand Area

Cleanup/water/drain area

The basics:

- Electrical: The main electrical box (200 amp service) for the house is nearby. There is an existing, dedicated 30a double-pole breaker in the box with a 10/3 wire run (see diagram), but no plug is installed. Also, no GFCI right now, but I think I'd probably just have a 30a GFCI breaker installed in the box. Also, a 120v outlet on a separate circuit is already wired (but could easily be moved a bit) in the space. (EDIT: will be running 6/4 from the panel with a 50a GFCI breaker.)

- Ventilation: A dryer was apparently installed here at one time. There is an existing 2-pane window (recessed ~ 6 inches), which 1 pane has been changed to plywood with a ~4" hole in place for the dryer vent. This could easily be changed to provide a larger outlet directly outside. Also, the walk-out door for the basement is ~ 5 feet away, which would be easy to crack open to provide replacement air as needed.

- Water/drainage: If you put your back against the wall in the diagram, about 8 feet away (in the middle of the room) is where the washer(s) was previously installed. There is currently a slop sink, multiple operating (and free) hot & cold water faucets, and a floor drain. The slope of the concrete floor doesn't allow for easy drainage (i.e. I can't just slop water everyone and expect it to find the drain), but it is close enough that hoses could easily be ran to it for drainage if I'm careful.

After doing a little research, this seems like a pretty ideal setup other than the lack of really clean drainage. Does anybody see anything glaring that I'm missing here?

Last edited: