evening everyone, I've purchased a 3kw heater for my keggle I shall be building

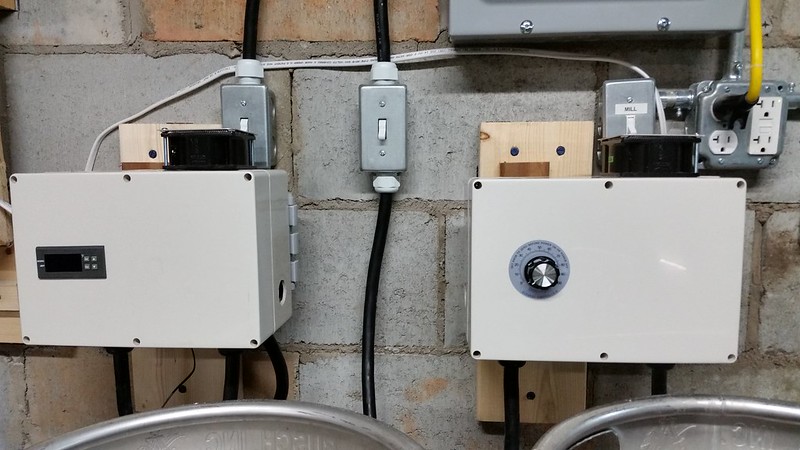

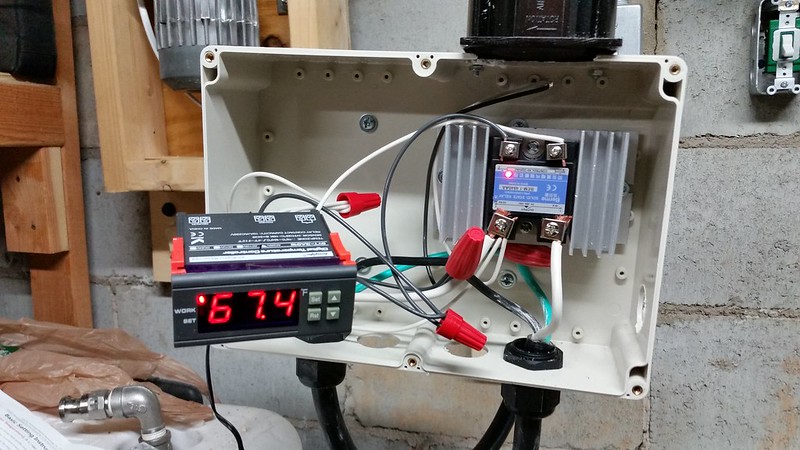

I'm looking to build a controller which will work that will be able to read the temperature and turn the element on or off accordingly.

I built something similar sometime ago for the fermentation fridge using an stc-1000

But read that it would be no good for an element of that power (3kw running on 240v)

Has anyone built something that would work .

Thanks

I'm looking to build a controller which will work that will be able to read the temperature and turn the element on or off accordingly.

I built something similar sometime ago for the fermentation fridge using an stc-1000

But read that it would be no good for an element of that power (3kw running on 240v)

Has anyone built something that would work .

Thanks