Liveforliving

Well-Known Member

- Joined

- Aug 3, 2014

- Messages

- 59

- Reaction score

- 2

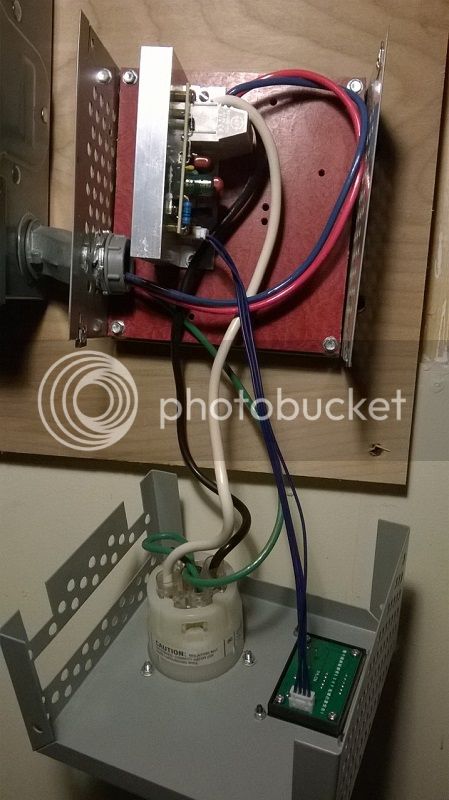

After fighting for smart ways to use propane inside the house, I finally learned that I'm not going to be able to pull it off (smartly). However, I've learned the joys and wonders of electric brewing.

So, to start using electric, I need to buy an element. Currently I'm brewing 5 gallon batches. Can I buy a 5500 element, or is that too big? I'm hoping as I grow to bigger batches, the elements can move with me.

Does anyone recommend a certain element? I read a lot from theelectricbrewing.com, ebrewsupply.com, and highgravitybrew.com- boilcoil. Is there a top brand or website?

And if I understand right, all I need to do is install the element and plug it in (might need to install a 240v outlet)? And it's easy to upgrade the system as I go? No more gas. Almost sounds too perfect to be true!

So, to start using electric, I need to buy an element. Currently I'm brewing 5 gallon batches. Can I buy a 5500 element, or is that too big? I'm hoping as I grow to bigger batches, the elements can move with me.

Does anyone recommend a certain element? I read a lot from theelectricbrewing.com, ebrewsupply.com, and highgravitybrew.com- boilcoil. Is there a top brand or website?

And if I understand right, all I need to do is install the element and plug it in (might need to install a 240v outlet)? And it's easy to upgrade the system as I go? No more gas. Almost sounds too perfect to be true!