Once I got the plastic enclosure, I realized the bottom wasn't flat. I bought a sheet metal subpanel:

http://amzn.com/B005UPERKY

$14.00 each

I had to buy a couple drill bits to drill holes for the contactor(bigger hole) and the terminal strips(smaller holes). I also had to buy some M5 and M6 screws and nuts to attach the terminal strips and contactors to the sub panel.

2 Contactors:

http://amzn.com/B001KGSJ74

$9.95 each

2 Fuse Panel Mount Holders from eBay

http://r.ebay.com/8vUCTm

$2.99 each + $2.50 shipping

I went to Radio Shack and bought a pack of 1A fuses, and a pack of 10A fuses. $2.50 each pack. If your local radio shack hasn't closed, I would use them. They are more expensive on Amazon.

Terminal Strips:

one for 120V:

http://amzn.com/B005I03WOI

$5.94 each

(comes with two, really just needed one, this will fit either 6 or 8 stud size terminal connectors, but they are pretty big, so I used the smaller one for ground)

one for ground:

http://amzn.com/B008X0NNEY

$6.00 each

(comes with 5, I originally thought I could use this for the 120V, but they are really small. They will NOT fit 6 or 8 stud size terminal connectors. I just stuck 10 AWG wire under the screws with no terminal connectors, seemed to work fine.)

14 Gauge wire

http://amzn.com/B00INVEUNQ

$6.49 each

This is all black. I really liked this wire. Its 25 Feet. I would buy two of these in retrospect. I ran out and had to buy 10 more feet at the local Ace hardware. The Ace hardware wire wasn't as nice. Since it was all black, I used some different color electric tape to mark the wires. I used blue tape to show the wire went to 120V, white tape to show that it went to neutral, and yellow tape to show that it went to ground. It seemed silly to buy 3 different colors of wire for both 10 AWG and 14 AWG wire. Totally a preference thing.

10 Gauge wire

http://amzn.com/B00INVF6P2

$11.33 each

I still had some of this left, but you need this. I used it to attach to and from any receptacle that had 240V. That's the inlet from the wall to the box, and from the element socket to the contactors.

Terminals. I bought mine on Amazon, but I got one entire box of the wrong size, one that I used a few of, and another I never used(thought I could have).

14 AWG #6 stud spade terminals

I would suggest getting about 50 with a number 6 stud that fit 14 AWG wire(like these:

http://amzn.com/B005HQ4QTI , $6.39 is cheap for 100 of them, though you don't need that much).

14 AWG female disconnect terminals

http://amzn.com/B00030CT56 $5.99 for 10.

These are more expensive, but you need them to connect to the switch for the relay on each side of the contactor. They are connected to the 14 AWG wire. I didn't have these in my original Amazon order. I ended up getting them at the local hardware store.

10 AWG #8 stud spade terminals

I also used some 10 AWG spade connectors. I actually only used like 10. Its only $4.50 for 50 of them:

http://amzn.com/B000BVZBS4

Jumpers

http://amzn.com/B000K2IL1I

$3.69 each

Buy two packs. I jumpered the bigger 8 position terminal to have the bottom 4 terminals be neutral and top 4 for 120V. For the ground, I didn't have small jumpers, so I just used small pieces of 14 AWG wire to jumper those.

I attached the two contactors and two terminal strips to the metal sub panel. I wired up the inlet for the 240V power to one of the contactors, hooked up to the ground and neutral terminals, and hooked up the red power illuminated push button.

I just used the screw connectors on each side of the relay and put bare 10 AWG wire underneath the screw terminals and tightened them down. For the switch that trips the relays, I used the female terminal disconnects with the 14 AWG wire.

Drilled holes in the sub panel. It was a lot harder than I thought. I should have used a center punch (like this one

http://amzn.com/B0037UUO60 ). The drill bit was sliding all over the place, and it was hard to get the holes just right, so things just barely lined up. I only ended up drilling two holes for each of the contactors, but I don't think they are going anywhere!

Here it is all wired up

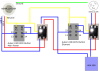

Here is my wiring diagram for the pieces I hooked up.