flexmurphy

Member

- Joined

- May 15, 2014

- Messages

- 10

- Reaction score

- 3

I'm sure there's already a post addressing this, but I haven't been able to find it.

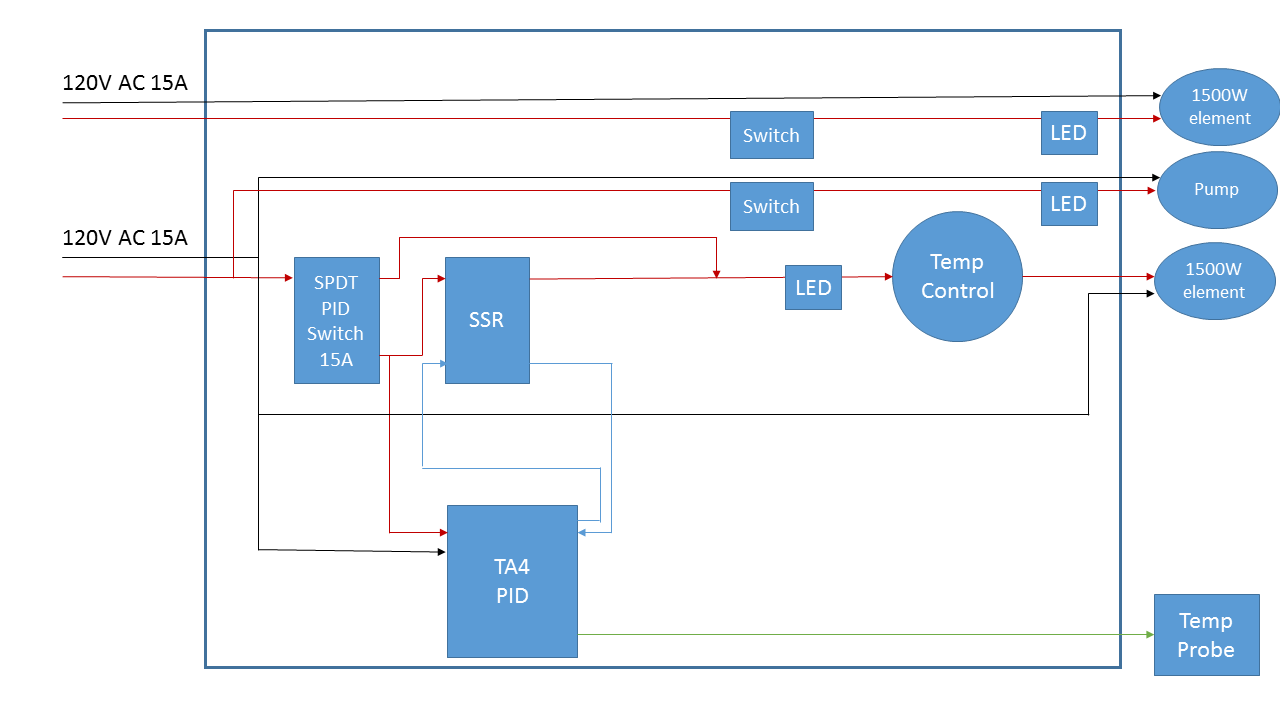

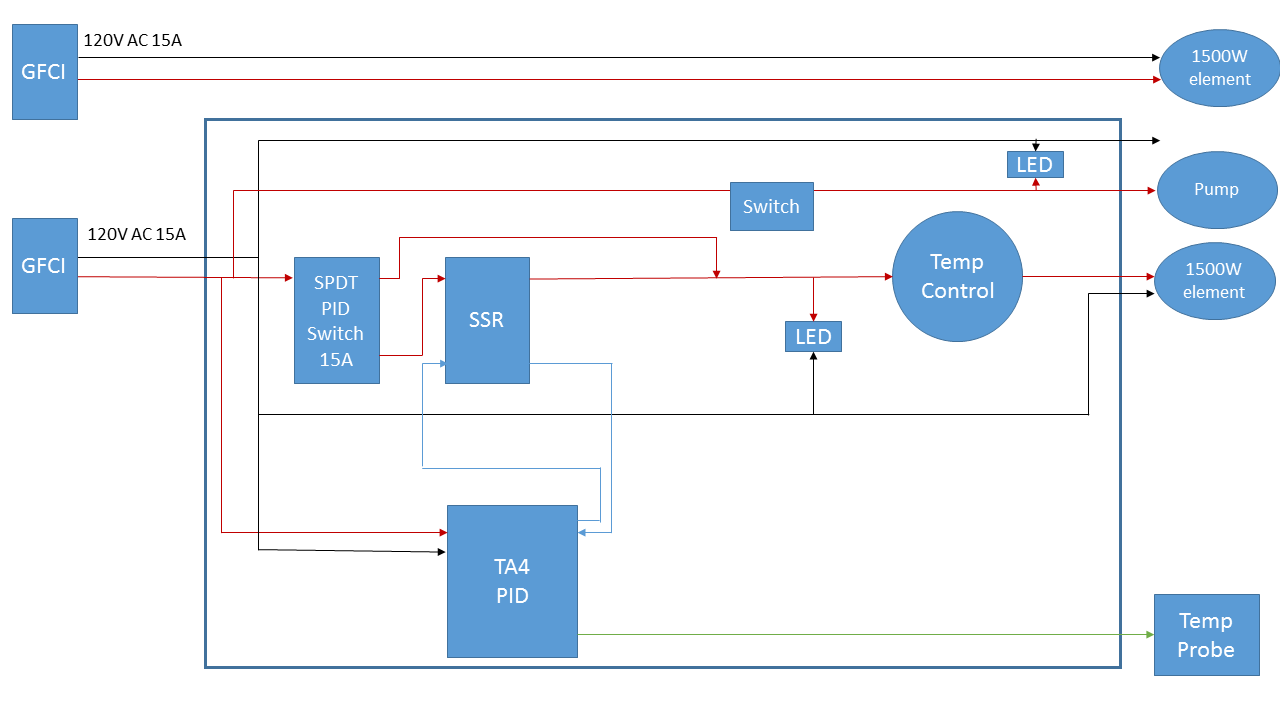

I'm designing an electric brewing controller with the following characteristics:

- Dual 120V 1500W heating elements

- Pump control

- Element 1 is straight on/off at full power

- Element 2 is able to switch from PID/SSR temperature control to manual on using a three-position on/off/on SPDT switch

- In either PID or manual mode, Element 2 also has a manual temperature control dial to adjust heat output

- LED indicator lights on all three loads (Element 1, Element 2, Pump)

I've attached a diagram illustrating how I imagine this working - if there's anyone who feels like taking a look and letting me know if it makes sense, it would be much appreciated.

Thanks!

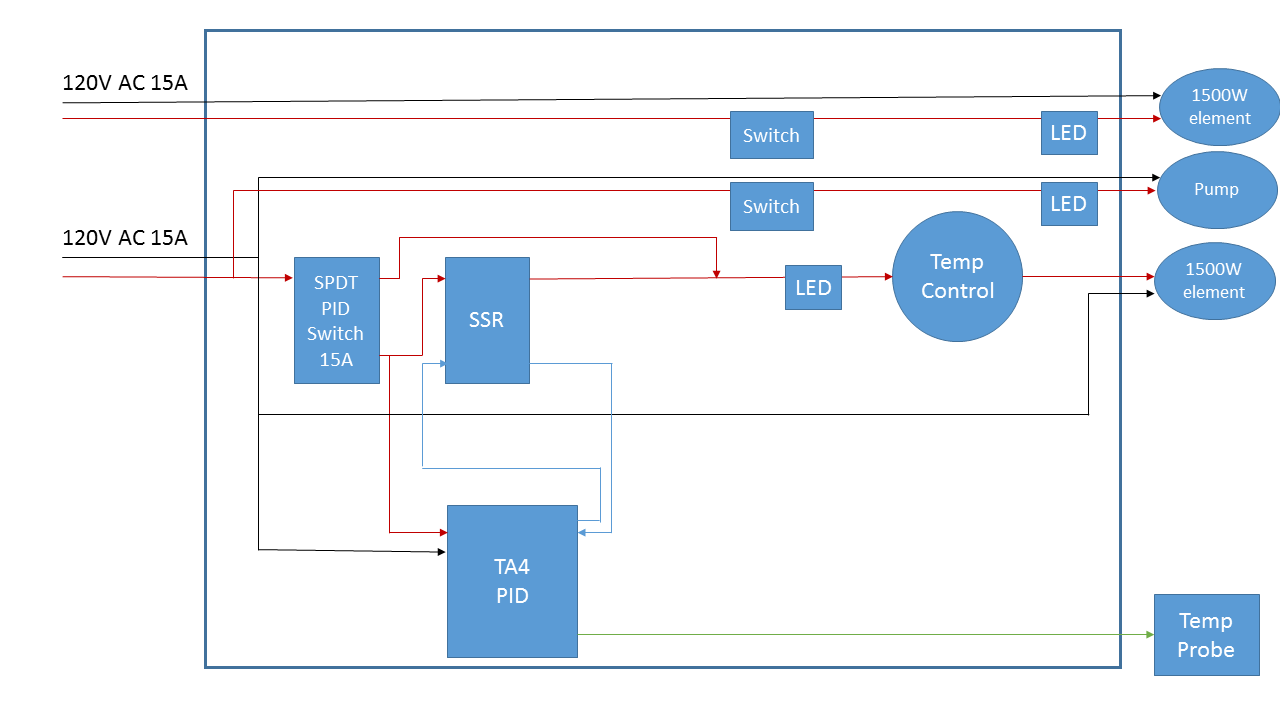

I'm designing an electric brewing controller with the following characteristics:

- Dual 120V 1500W heating elements

- Pump control

- Element 1 is straight on/off at full power

- Element 2 is able to switch from PID/SSR temperature control to manual on using a three-position on/off/on SPDT switch

- In either PID or manual mode, Element 2 also has a manual temperature control dial to adjust heat output

- LED indicator lights on all three loads (Element 1, Element 2, Pump)

I've attached a diagram illustrating how I imagine this working - if there's anyone who feels like taking a look and letting me know if it makes sense, it would be much appreciated.

Thanks!