Well I've been browsing this electric brewing section for a long time now. Researched all the regular electric brewing sites. Watched all the you tube videos I could fine. Saved most of my beer brewing money and slowly purchased all the pieces and parts I would need to upgrade my brew house to electric. I big thanks to: Kal and theelectricbrewery.com, Bobby and all his stainless parts at brewhardware.com and Ryan at ebrewsupply.com. I also have to mention Hunter306 and his build as I "borrowed" a lot of his layout mainly because it was exactly what I was looking at doing anyway.

Last summer I upgraded all my keggles to full stainless and got rid of all the weldless fittings I had and silver soldered all couplers in. These are Bobby's 1.5" tri-clover silver solder element mounts. I will be polishing the bottom of the kettle once I'm full electric.

I got in on the HD copper close out. 50' HERMS coil installed in the HLT.

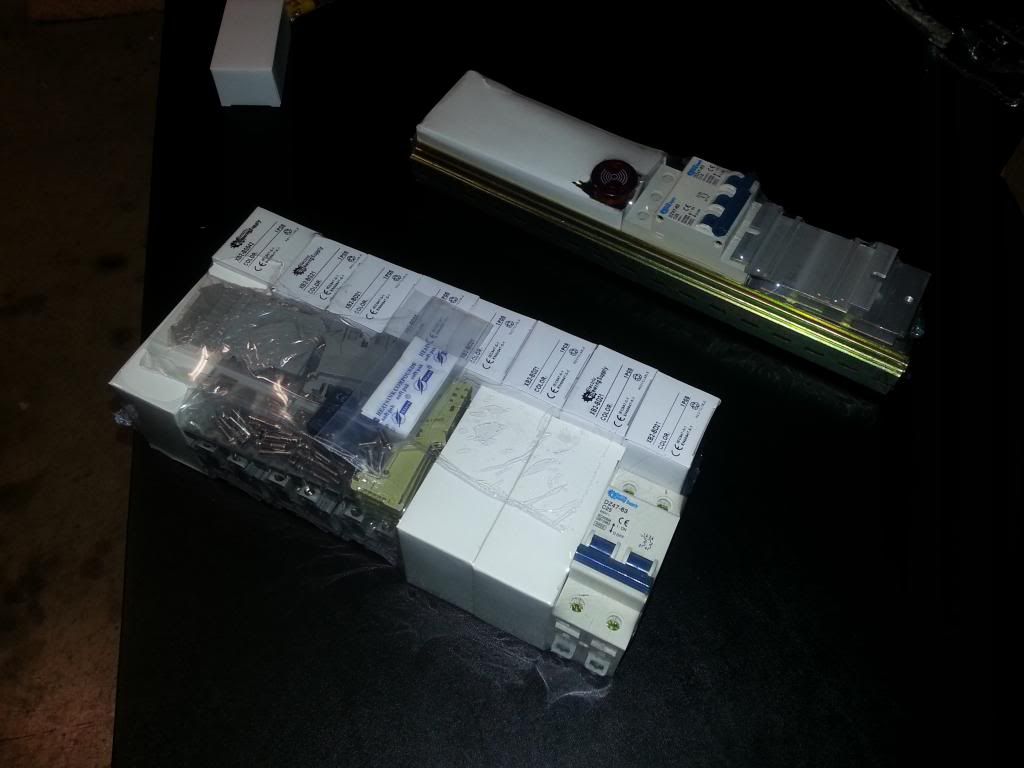

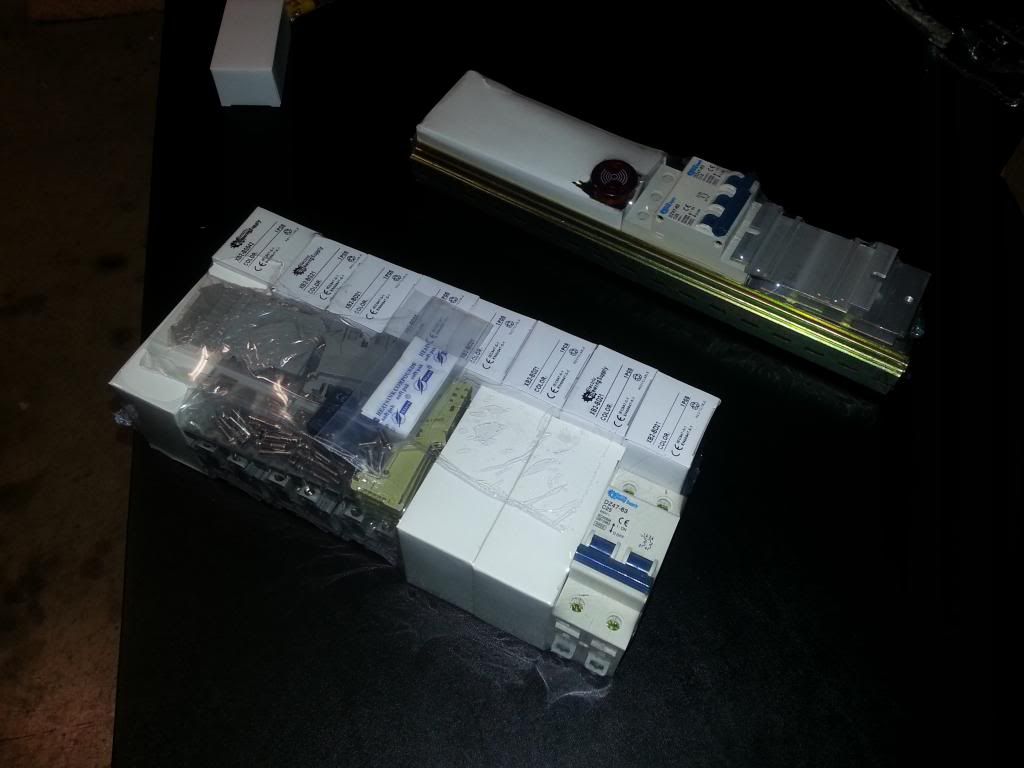

Got to say I'm very impressed by the packaging that Ryan @ ebrewsuppy did. Both packages are wrapped in shrink wrap. Nice and neat so nothing was rattling around in the box when I received it. That's the DIY 50amp PID kit.

And the big shot! Everything laid out on the table. This is everything from the pumps ,20' of 6/3 wire for the spa panel wiring to the crimps, temp probes and SSR heat sink. Sorry for the bad picture I had to do a panorama shot.

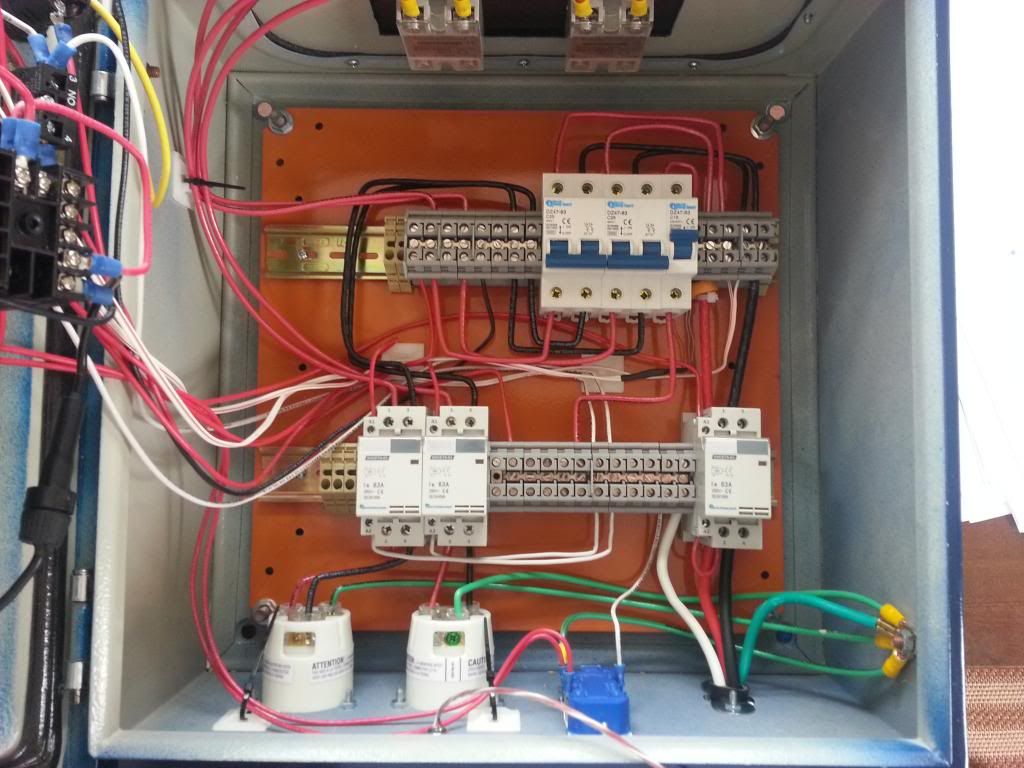

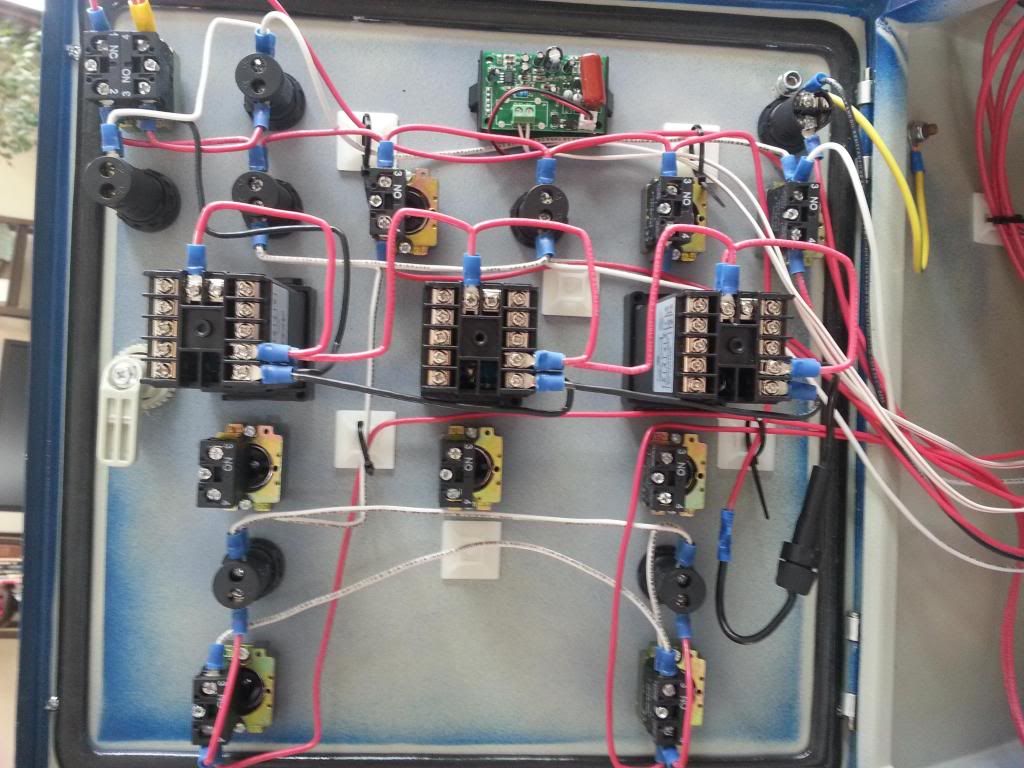

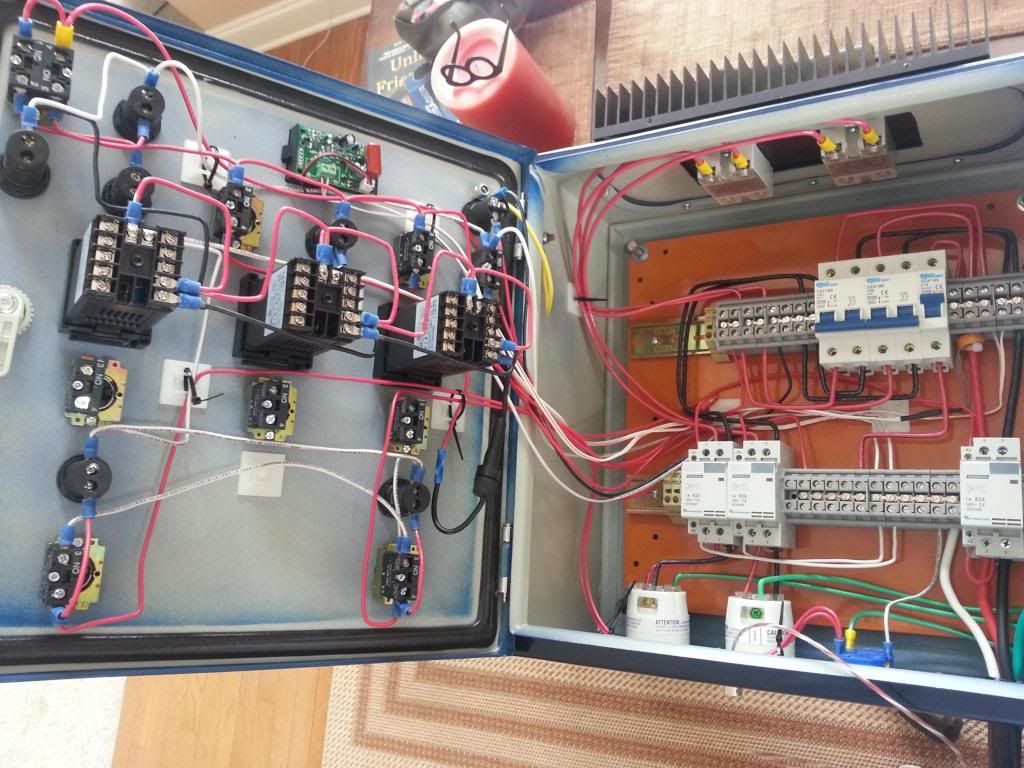

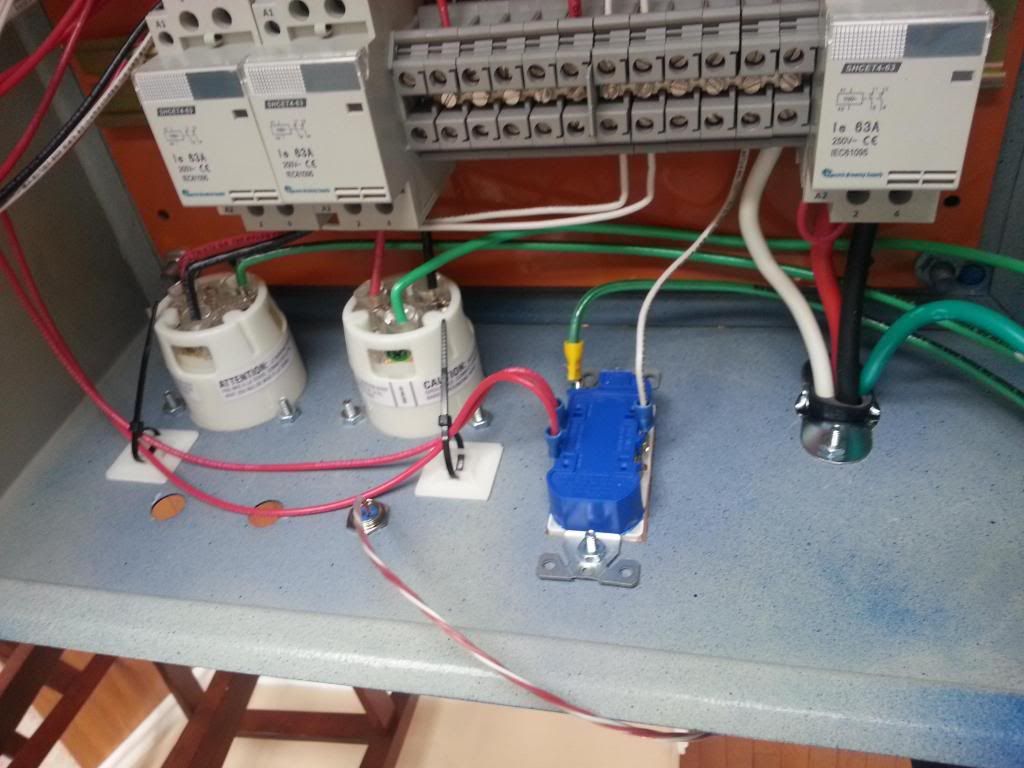

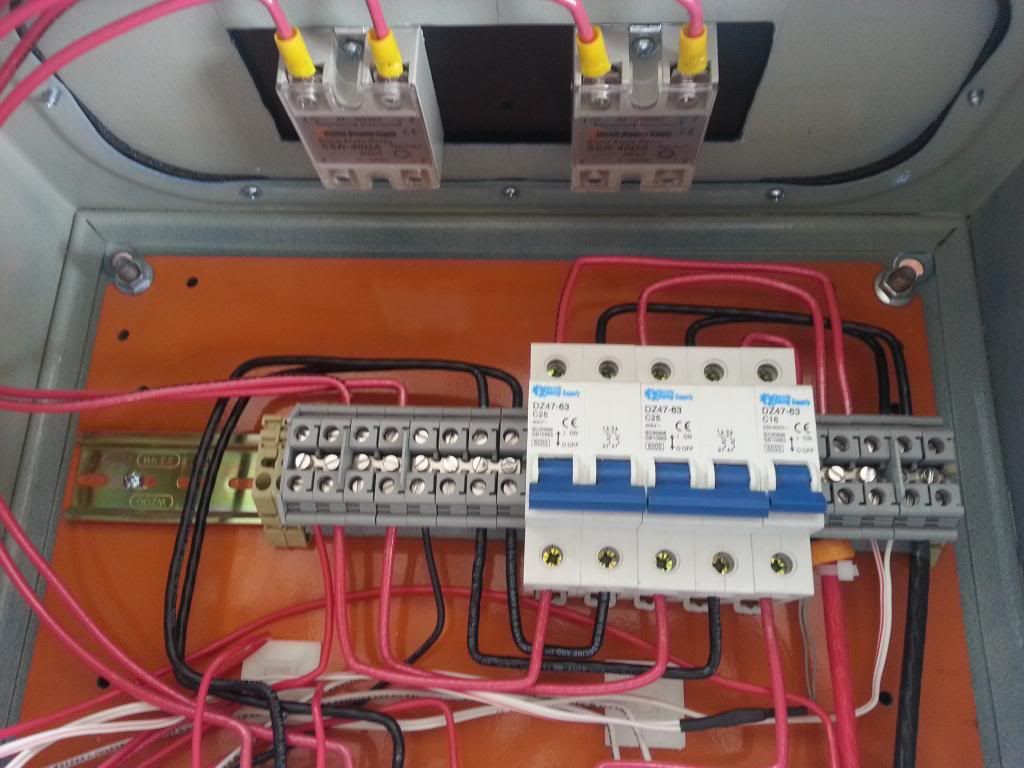

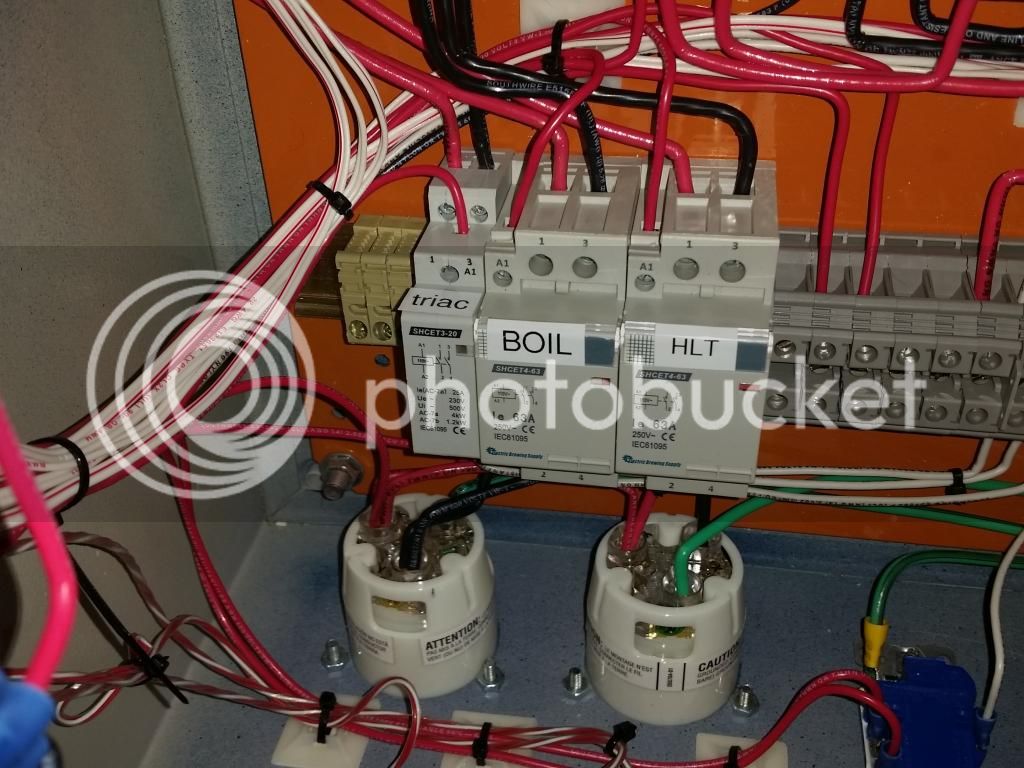

Here is the panel layout. It's Kal's layout with a few minor tweaks. Since I'm not using the panel timer I only have 3 holes for the PIDs. I'm also not using separate volt and amp meters. BTW that 7/8" q-max punch was the best $15 I spent on this build.

Primed and ready for paint. I used a jig saw with a metal blade to cut the PID and ammeter holes.

Last summer I upgraded all my keggles to full stainless and got rid of all the weldless fittings I had and silver soldered all couplers in. These are Bobby's 1.5" tri-clover silver solder element mounts. I will be polishing the bottom of the kettle once I'm full electric.

I got in on the HD copper close out. 50' HERMS coil installed in the HLT.

Got to say I'm very impressed by the packaging that Ryan @ ebrewsuppy did. Both packages are wrapped in shrink wrap. Nice and neat so nothing was rattling around in the box when I received it. That's the DIY 50amp PID kit.

And the big shot! Everything laid out on the table. This is everything from the pumps ,20' of 6/3 wire for the spa panel wiring to the crimps, temp probes and SSR heat sink. Sorry for the bad picture I had to do a panorama shot.

Here is the panel layout. It's Kal's layout with a few minor tweaks. Since I'm not using the panel timer I only have 3 holes for the PIDs. I'm also not using separate volt and amp meters. BTW that 7/8" q-max punch was the best $15 I spent on this build.

Primed and ready for paint. I used a jig saw with a metal blade to cut the PID and ammeter holes.