kgx2

Well-Known Member

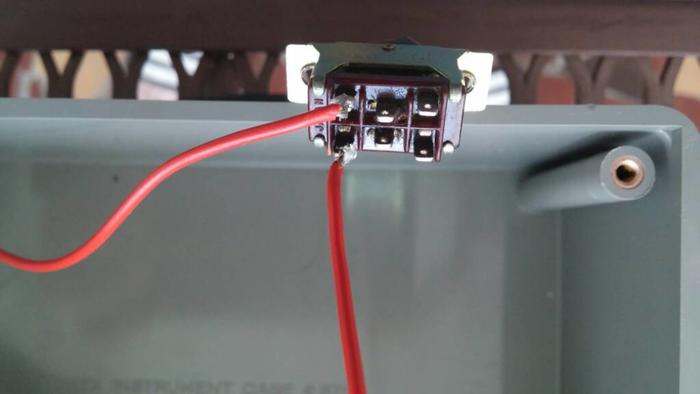

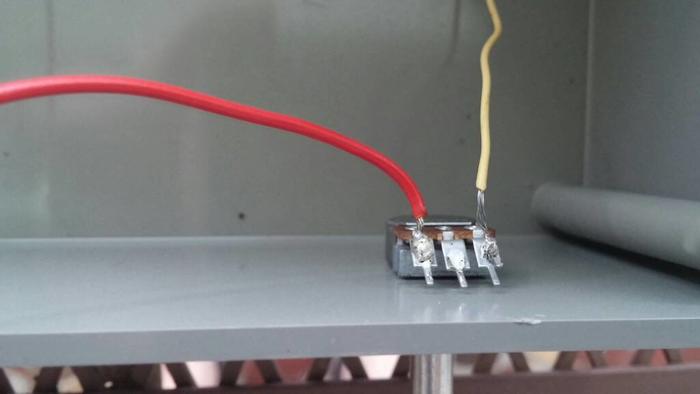

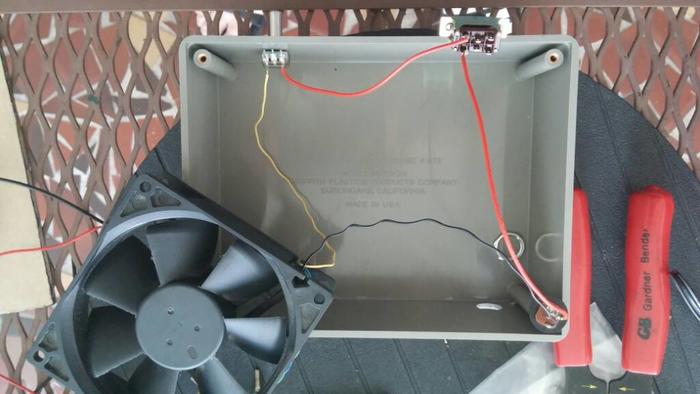

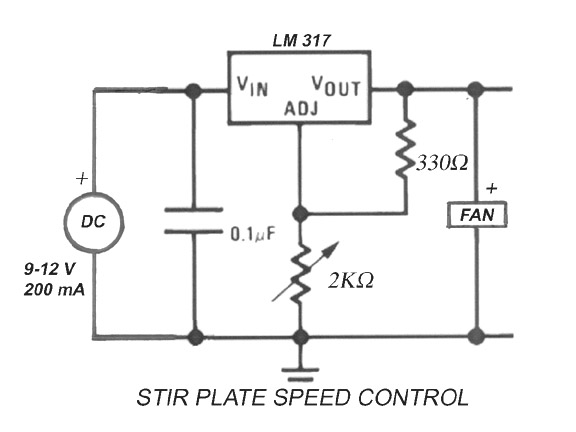

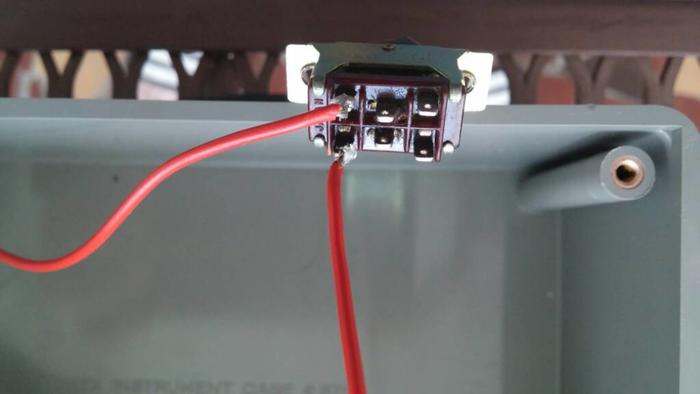

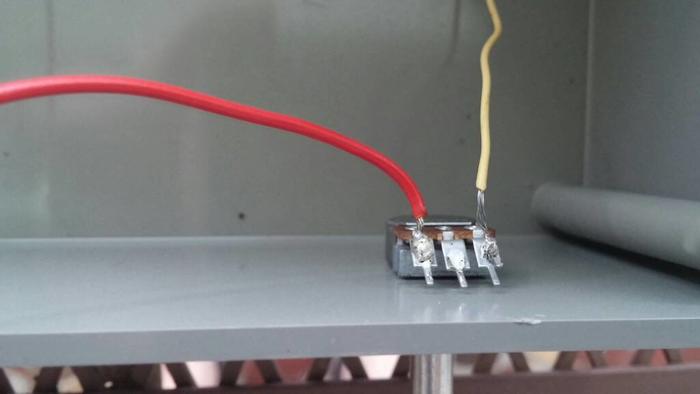

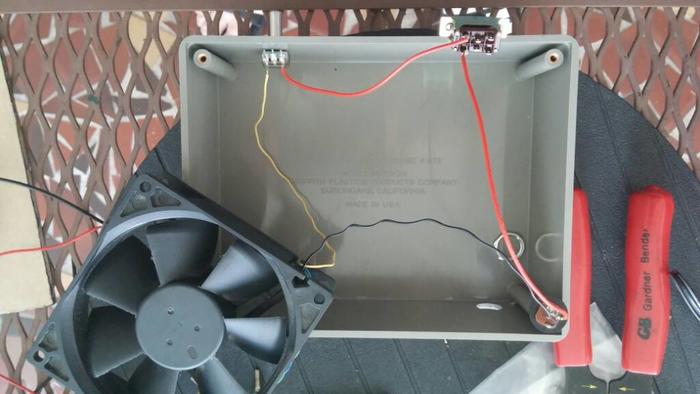

So I've tried to make my own stir plate but after getting everything together and soldering it up nothing works. I'll be the first to say I know little to none about electric wiring but can build anything with good instructions (especially with diagrams). This seemed to be a very simple project so I figured I'd give it a shot. I tried switching the power wire on the potentiometer and that didn't help either. Using a 6V 1A power supply, old pc case fan 120mm 12V .6A, potentiometer, power inlet connector (no idea real name) & and a toggle on/off switch.

I know the power supply is lower than the fan but I tired another supply and still nothing so I don't think it's the supply. There seems to be very few things I could do wrong here as it really is a pretty simple circuit right?

Any help would be great! I'm going to get another new fan and see if this one was just dead as it did come from a retired pc.

Here are some pics of the project and components.

I know the power supply is lower than the fan but I tired another supply and still nothing so I don't think it's the supply. There seems to be very few things I could do wrong here as it really is a pretty simple circuit right?

Any help would be great! I'm going to get another new fan and see if this one was just dead as it did come from a retired pc.

Here are some pics of the project and components.