Roger - thanks for the links. Reading the descriptions, the plastic one is pre-mix, which usually means 10-30psi from what I've read. I ran across this and thought it might work (chrome plated brass):

http://www.ebay.com/itm/Hot-Water-F...-12915-0000-/200918335663?hash=item2ec7aa80af

bryan - I looked at your setup, and having a secondary tank pre-carbonator in the fridge with the carbonator is brilliant - really opens up options due to the lower pressure! I realized that you could put a T before the carbonator for a chilled still water output as well if desired (and filtered if you have that in the line, too).

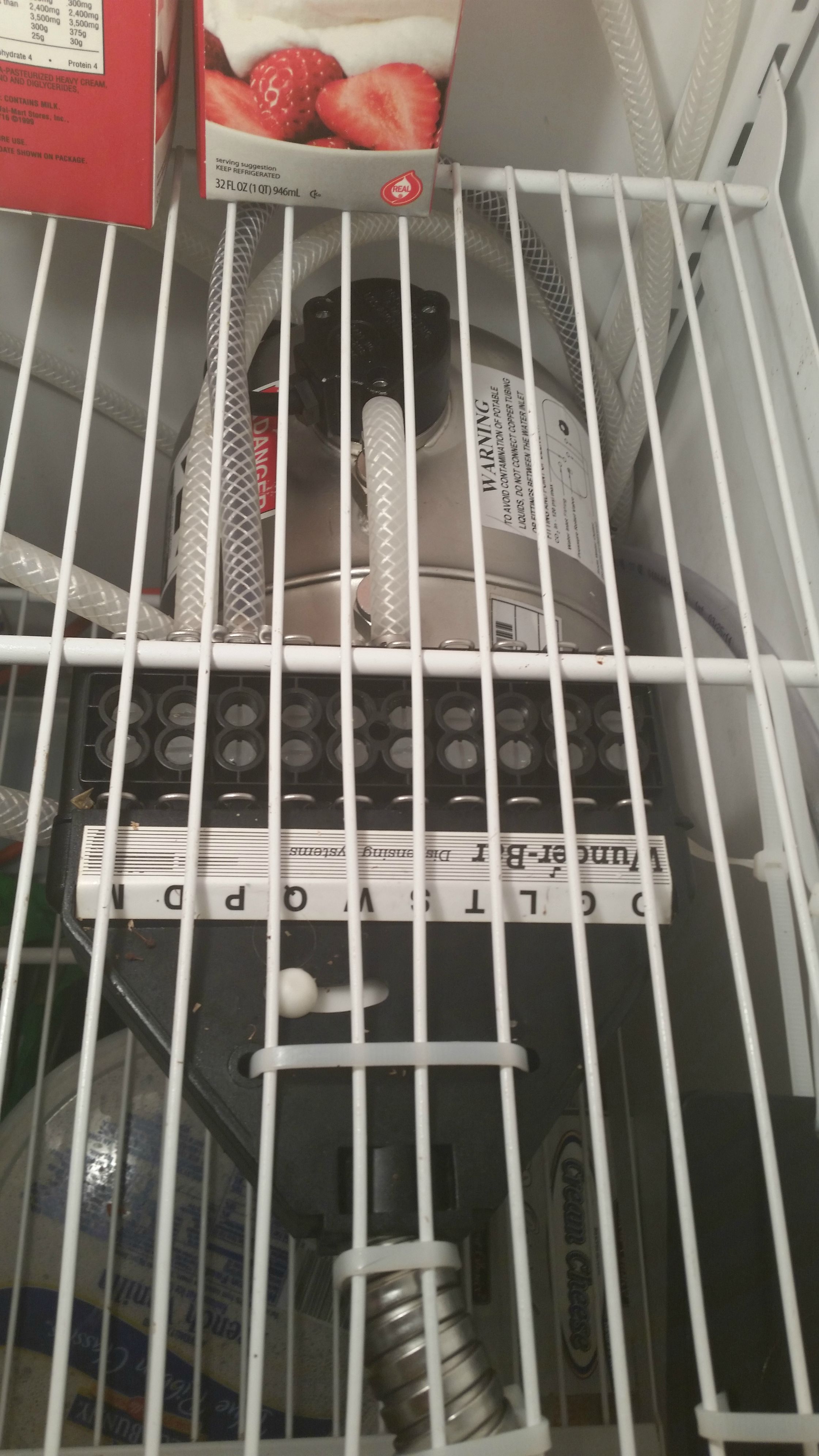

Taz - thanks for the feedback about your setup! I've decided to just put the carbonator tank in a very small throwaway used mini fridge to test for a while before permanent installation. I'm excited about getting it working with just the refrigerated carbonator tank. I have a garden hose bib rated at 120 psi I've been using for testing (I may just install that as my tap lol), and I'll probably just coil that in the fridge for the moment so I can get to a point where I'm happy with the performance before spending more and installing permanently.

So it looks like I'm going to need a few more fittings, but I'm having trouble finding the ones I want. Can anyone point me to a source of 90 degree bend barbed 3/8" hose to male 3/8" flared fittings? I need three of those, a smaller 90 degree bend for the co2 hose (1/4 maybe) and a length of hose (my local ace has spools of the reinforced hose for like 1.24/foot).

Thanks again for all of the great info and support guys! Glad I stumbled on this site and thread.