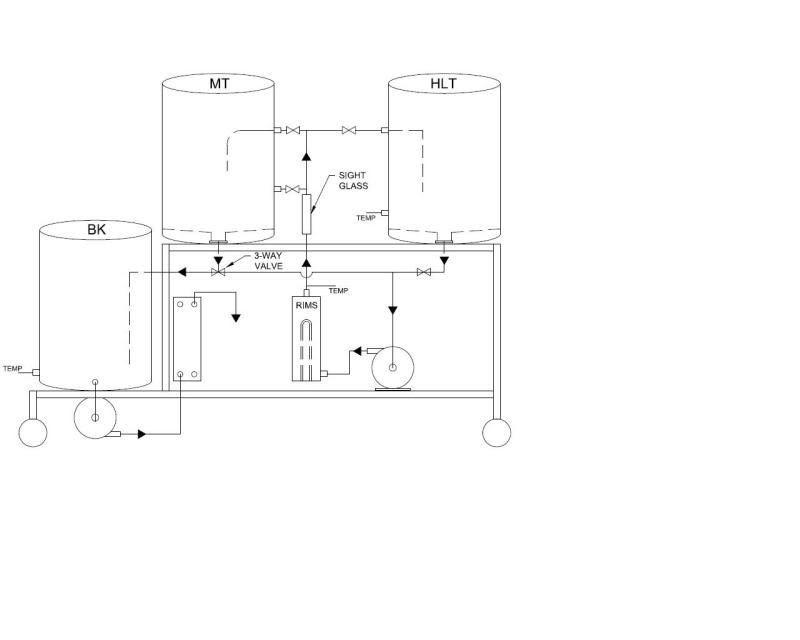

I have the plumbing pretty much the way I would like it, but wanted to see if people have any suggestions or see any flaws. Here is some background info regarding the drawing and layout: the arrows indicate flow; electric elements in the BK, HLT and RIMS; controlled via BrewTroller; included a loop from HLT through RIMS just to speed up water heating. Let me know what you think. The drawing is to scale except I had to stretch the frame left to right to show the plumbing clearly. I have the frame built and its nice and compact.

View attachment Pickles Brewery Plumbing Layout2 (1).pdf

View attachment Pickles Brewery Plumbing Layout2 (1).pdf