thelema5

Well-Known Member

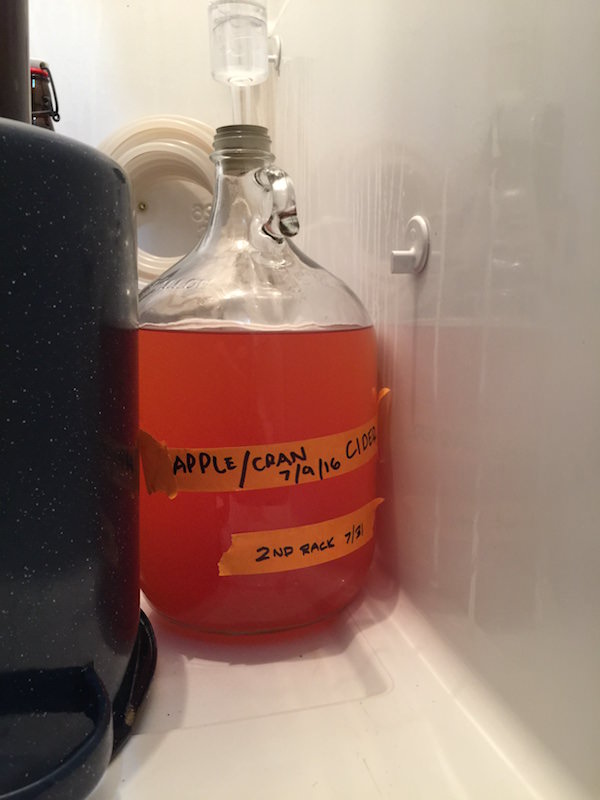

This is one of my go-to recipes for a clean, tart, and super refreshing cider perfect for summer cookouts and lazy picnics.

It finishes as a crisp, pinkish, crystal clear cider which is super easy-to-drink, fruit forward, and semi-sweet.

The recipe below will yield one gallon, but it can be easily scaled for larger batches.

Cranberry Splash Cider

Blend and Pasteurize

Notes:

For me this yielded a very drinkable 7% ABV. The corn syrup is not a fully fermentable sugar- if also adds viscosity and residual sweetness.

The cranberry juice I used was a "Cranberry Juice Cocktail from Concentrate", the ingredients were: 'filtered water, cranberry juice concentrate, cane or beet sugar, vitamin C' it was NOT a juice blend

My last batch took about 3 weeks to ferment out at 65 degrees. It was racked into secondary for another 5 weeks and bottled.

A month of bottle conditioning has left this cider a bright, fruity joy to imbibe. I hope you love it as much as I do.

It finishes as a crisp, pinkish, crystal clear cider which is super easy-to-drink, fruit forward, and semi-sweet.

The recipe below will yield one gallon, but it can be easily scaled for larger batches.

Cranberry Splash Cider

Blend and Pasteurize

- 4 cups cranberry juice

- 8 ounces light corn syrup

- 6 ounces frozen apple juice concentrate

- +/- 96 ounces pasturized apple juice

- 1 bag black tea, brewed

- 1/2 teaspoon malic acid

- White Labs Cider Yeast

Notes:

For me this yielded a very drinkable 7% ABV. The corn syrup is not a fully fermentable sugar- if also adds viscosity and residual sweetness.

The cranberry juice I used was a "Cranberry Juice Cocktail from Concentrate", the ingredients were: 'filtered water, cranberry juice concentrate, cane or beet sugar, vitamin C' it was NOT a juice blend

My last batch took about 3 weeks to ferment out at 65 degrees. It was racked into secondary for another 5 weeks and bottled.

A month of bottle conditioning has left this cider a bright, fruity joy to imbibe. I hope you love it as much as I do.