AussieDamo

Active Member

Hi gents,

I'm in the process of finishing up installing a new Craft Beer Growler system for work.

It will consist of glass Growler bottles being Counter Pressure filled with stainless steel dispenser guns via lines running from the cool room containing pressurised kegs and the Co2 with regulator.

BACKGROUND: We previously had faulty system in place fitted over a decade ago and when it died I decided I would rip it all out and build something properly from the ground up. So I completely replaced the lines with brand new python, replaced the splices/joiners and every clamp etc.

Therefore, I now have it set up so that a single line runs off the Co2 via the regulator which is then split into a T piece for a line to branch off for Keg 1 and then another T further along the line for Keg 2. The line then continues on through the wall and up the outer wall where it is split once again to feed both guns their Co2.

New dedicated beer lines for keg 1 and keg 2 run straight from the keg through the wall and into their respective guns' beer inlets.

PROBLEMS: I am finding their seems to be gas constantly leaking from around the inlet valve/tubing area. I have clamped the tubing vigorously and tightened the thread sitting on both inlet sides as much as I can. Any thoughts?

There also seems to be gas coming down the stem sometimes even in the closed position also. It wasn't so bad when I turned the pressure down but it still shouldn't be happening. I want to have the system air-tight enough to not have to run and turn the gas on and off constantly.

Furthermore, what PSI/KPA is ideal for these systems? I read on a forum somewhere that 8-18PSI is normal... this seems incredibly low to me?? That said, I've only ever used more conventional systems before. I have a feeling my regulator would flip out trying to pressure at below 100kpa?

Also, the damn guns came with no booklet, installation instructions etc. so as silly as it sounds I just assumed that the inlet on the left hand side in the pic sitting over the blow off valve would be 'gas in'. Through trial and error I think it may in fact be the other way?? But that seems odd to me as well. I could be making things worse by forcing beer through the gas inlet haha ah welllll

ah welllll

In any case, I look forward to hearing from you ever helpful lads

Item diagram pic:

Tap with valves closed. ( I know I don't have the Beer intake tubing clamped here. I had it loose to try a few different things.

A few close ups of the assembly an some number designations that don't mean a lot to me haha

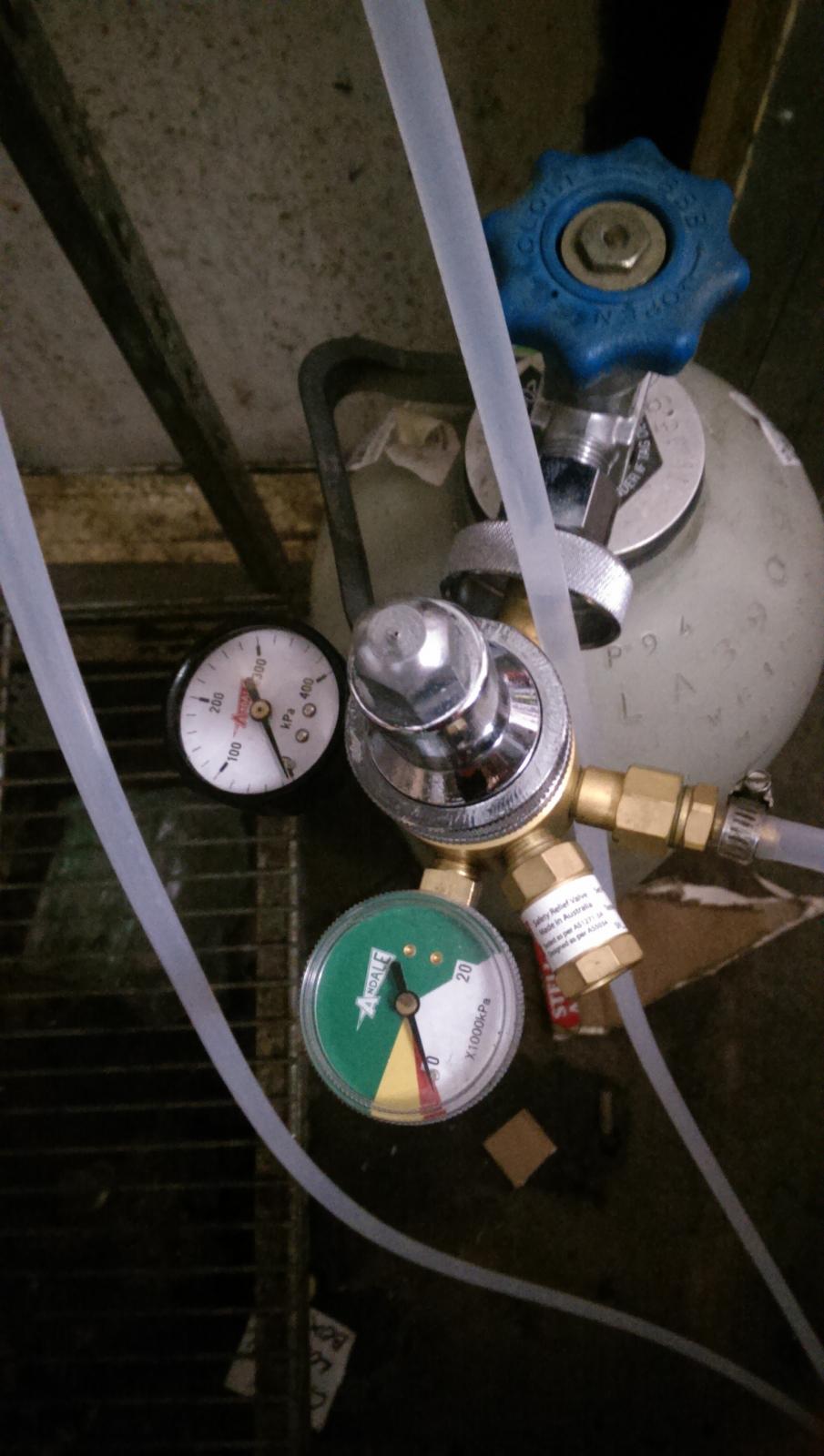

A quick diagram of the setup before the guns were attached.

These are the lines coming up and along the wall before dropping down on the visible wall in the previous pic. The gas line is obviously the one splitting off in the T-piece.

I'm in the process of finishing up installing a new Craft Beer Growler system for work.

It will consist of glass Growler bottles being Counter Pressure filled with stainless steel dispenser guns via lines running from the cool room containing pressurised kegs and the Co2 with regulator.

BACKGROUND: We previously had faulty system in place fitted over a decade ago and when it died I decided I would rip it all out and build something properly from the ground up. So I completely replaced the lines with brand new python, replaced the splices/joiners and every clamp etc.

Therefore, I now have it set up so that a single line runs off the Co2 via the regulator which is then split into a T piece for a line to branch off for Keg 1 and then another T further along the line for Keg 2. The line then continues on through the wall and up the outer wall where it is split once again to feed both guns their Co2.

New dedicated beer lines for keg 1 and keg 2 run straight from the keg through the wall and into their respective guns' beer inlets.

PROBLEMS: I am finding their seems to be gas constantly leaking from around the inlet valve/tubing area. I have clamped the tubing vigorously and tightened the thread sitting on both inlet sides as much as I can. Any thoughts?

There also seems to be gas coming down the stem sometimes even in the closed position also. It wasn't so bad when I turned the pressure down but it still shouldn't be happening. I want to have the system air-tight enough to not have to run and turn the gas on and off constantly.

Furthermore, what PSI/KPA is ideal for these systems? I read on a forum somewhere that 8-18PSI is normal... this seems incredibly low to me?? That said, I've only ever used more conventional systems before. I have a feeling my regulator would flip out trying to pressure at below 100kpa?

Also, the damn guns came with no booklet, installation instructions etc. so as silly as it sounds I just assumed that the inlet on the left hand side in the pic sitting over the blow off valve would be 'gas in'. Through trial and error I think it may in fact be the other way?? But that seems odd to me as well. I could be making things worse by forcing beer through the gas inlet haha

In any case, I look forward to hearing from you ever helpful lads

Item diagram pic:

Tap with valves closed. ( I know I don't have the Beer intake tubing clamped here. I had it loose to try a few different things.

A few close ups of the assembly an some number designations that don't mean a lot to me haha

A quick diagram of the setup before the guns were attached.

These are the lines coming up and along the wall before dropping down on the visible wall in the previous pic. The gas line is obviously the one splitting off in the T-piece.