You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Corny keg thermowell

- Thread starter McMullan

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

This long dip tube/thermowell is working nicely. It has to be inserted after fitting the lid. Tested it to 30psi. It's now in use monitoring an English Lager currently at 10psi, climbing to 15, before ramping up the temperature.

And I just noticed @FunkedOut did something very similar years ago What is it they say about great minds again?

What is it they say about great minds again?

And I just noticed @FunkedOut did something very similar years ago

FunkedOut

FunkedOver

- Joined

- Mar 23, 2017

- Messages

- 849

- Reaction score

- 417

Thanks for calling my name.

Nice work on the thermowel. You’re going to love the pressure fermenting. Especially the carbonation you end up with when it’s all over. Thebeer Is ready to drink as soon as the yeast drop out!

I still have a couple of 10 gallon corny kegs when you’re ready for 5 gallon batches (6 in the fermenting keg).

You really got my attention with the English lager thing.

I was living in a world where the English only brewed ales until this post.

What style/brand are you chasing here?

More info on that please…

Nice work on the thermowel. You’re going to love the pressure fermenting. Especially the carbonation you end up with when it’s all over. Thebeer Is ready to drink as soon as the yeast drop out!

I still have a couple of 10 gallon corny kegs when you’re ready for 5 gallon batches (6 in the fermenting keg).

You really got my attention with the English lager thing.

I was living in a world where the English only brewed ales until this post.

What style/brand are you chasing here?

More info on that please…

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

I quite enjoy a crisp, spicy Pilsner on a hot day. Just trying to mimic something that I'd be happy to serve during the summer, and to use up grain after panic buying a few sacks more than usual. Ironically, I just bought a sack of pilsner malt for the sake of comparisonThanks for calling my name.

Nice work on the thermowel. You’re going to love the pressure fermenting. Especially the carbonation you end up with when it’s all over. Thebeer Is ready to drink as soon as the yeast drop out!

I still have a couple of 10 gallon corny kegs when you’re ready for 5 gallon batches (6 in the fermenting keg).

You really got my attention with the English lager thing.

I was living in a world where the English only brewed ales until this post.

What style/brand are you chasing here?

More info on that please…

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

You need a 1/4" bulkhead type post fitting for the lid mod:

Generally, the thermowell is going to fit any corny keg post.

You'll need:

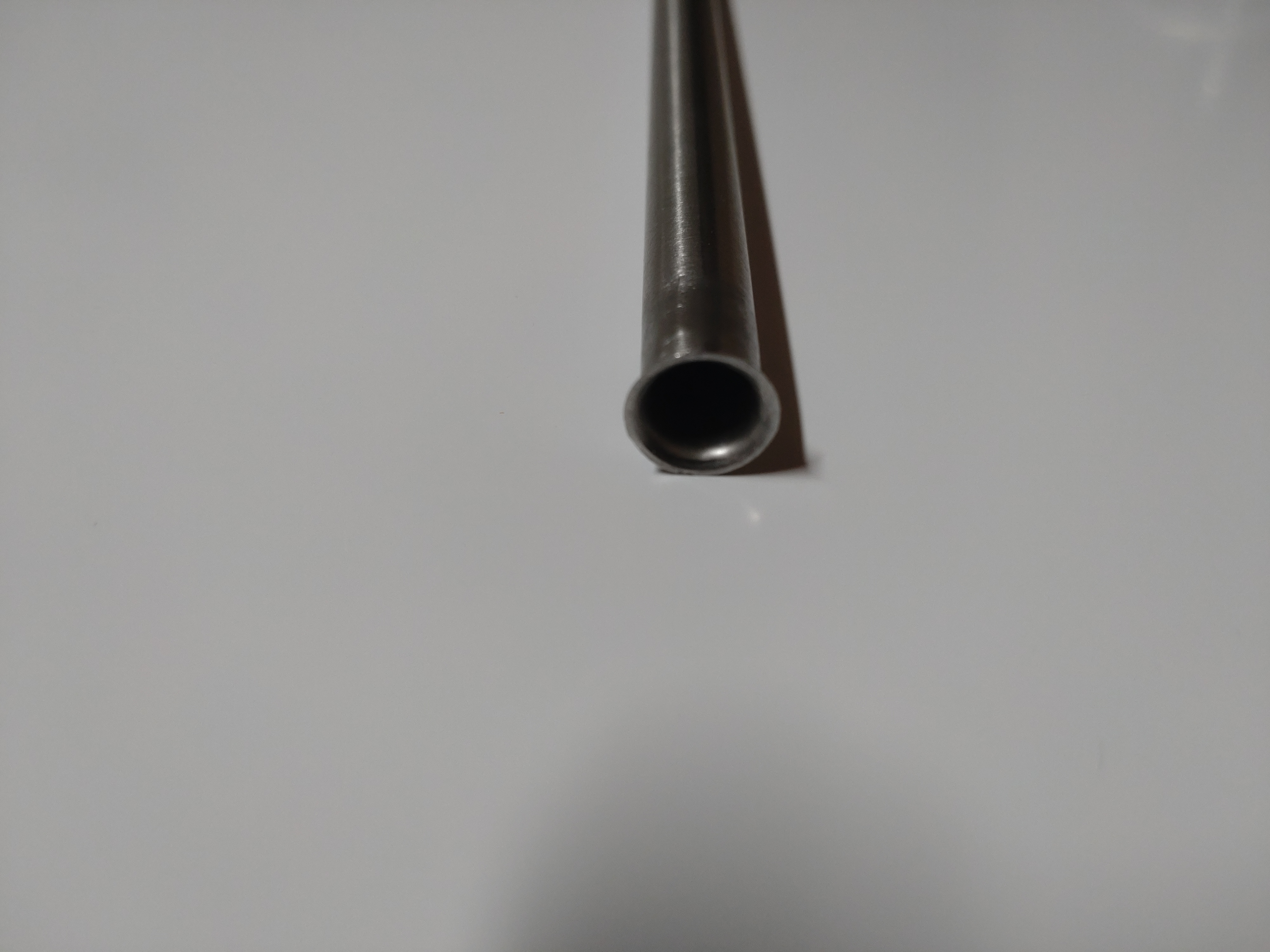

From left to right: 8mm OD stainless thermowell tube, which come in various lengths or be shortened with a small pipe cutter; post fitting with 19/32" - 18 thread; diptube o-ring; 8mm ID X 12mm OD stainless washer/shim about 1mm thick; spring is optional here, with these 'economy' posts; and the post with poppet removed, to accommodate the temperature sensor.

The open end of the thermowell tube needs to be flared with a brake line flaring tool. The washer helps keep it in place. I swapped the black rubber bulkhead o-rings with green FKM o-rings, which are much more robust.

Nice tight hole in the lid, too.

Generally, the thermowell is going to fit any corny keg post.

You'll need:

From left to right: 8mm OD stainless thermowell tube, which come in various lengths or be shortened with a small pipe cutter; post fitting with 19/32" - 18 thread; diptube o-ring; 8mm ID X 12mm OD stainless washer/shim about 1mm thick; spring is optional here, with these 'economy' posts; and the post with poppet removed, to accommodate the temperature sensor.

The open end of the thermowell tube needs to be flared with a brake line flaring tool. The washer helps keep it in place. I swapped the black rubber bulkhead o-rings with green FKM o-rings, which are much more robust.

Nice tight hole in the lid, too.

Last edited:

Have you compared the thermowell readings to a thermometer insulated and taped to the exterior? I've thought about doing this but wonder whether it's significantly different.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

I tape foam insulation over a temperature probe against the FV wall when I haven't got a spare thermowell. Does it make a noticeable difference? I can't say with any certainty, because I haven't really compared it. Peace of mind, at least, when you want to maintain fermenting wort temperature. Three temperature probes to monitor ambient/inside chamber, keg side wall and in the wort might be interesting. I've noticed my keezer's activity is a lot more stable with the probe is in the beer/keg during lagering and serving.Have you compared the thermowell readings to a thermometer insulated and taped to the exterior? I've thought about doing this but wonder whether it's significantly different.

Mac_rancher

Active Member

- Joined

- Apr 25, 2021

- Messages

- 28

- Reaction score

- 14

@McMullan Thank you so much for this. I've been brewing for a little while and I'm thinking about doing pressure fermentation for the first time in a corny keg. Glad I came across this thread and also happy to see it isn't years old. I wanted to ask your opinion with an option I was thinking about trying. I found this thermowell that is 1/2" NPT and this ball lock that is also 1/2" NPT. Theoretically these should go together tightly and withstand pressure if connected, right? NPT is tapered so It should create a very tight seal without needing to use Teflon tape.

Also, I have had a hard time finding a thread specifically on this so I was wondering about your experience. Do you start fermentation with pressure right away or do you give a day for the yeast to get up to speed before you apply pressure? I was thinking about starting with lower pressure around 5psi for the first day and then increasing to 10 or so. I will be adding yeast nutrient and oxygenating my wort, along with a yeast starter so I feel confident fermentation will kick off fine.

Edit: Forgot to mention I am thinking about doing a NEIPA/Hazy and want to lock in the hop aroma. Thinking about using some SS discs in the hop bag with a cow magnet on the outside. when its time to dry hop just pull the magnet and hopefully it would drop in (unless the SS disc becomes magnetized enough that it doesn't drop). Curious how you dry hop in this process too if you have any input with that.

Also, I have had a hard time finding a thread specifically on this so I was wondering about your experience. Do you start fermentation with pressure right away or do you give a day for the yeast to get up to speed before you apply pressure? I was thinking about starting with lower pressure around 5psi for the first day and then increasing to 10 or so. I will be adding yeast nutrient and oxygenating my wort, along with a yeast starter so I feel confident fermentation will kick off fine.

Edit: Forgot to mention I am thinking about doing a NEIPA/Hazy and want to lock in the hop aroma. Thinking about using some SS discs in the hop bag with a cow magnet on the outside. when its time to dry hop just pull the magnet and hopefully it would drop in (unless the SS disc becomes magnetized enough that it doesn't drop). Curious how you dry hop in this process too if you have any input with that.

Last edited:

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,438

@Mac_rancher, I'm not sure about your plan for a thermowell, because I haven't tried it. I think you might have to chop off some of the male thread on the ball lock fitting, to get a tight fit/seal. (It doesn't need to be much more than hand tight, because the o-rings do all the sealing. Too much and they get distorted and the seal gets broken.) Have a practice run on a piece of scrap sheet metal before sacrificing anything of value. You can ferment in a keg with a foam-insulated temp probe on the outside keg wall for the time being. Works fine.

What I do currently - for lagers - is let the yeast build up pressure naturally after pitching. Set the spunding to about 15psi and just monitor the pressure over the first day or two, to make sure the keg's sealed. No problems with leaks so far. Touch wood. My ales get fermented open then sealed up towards the end of fermentation, to naturally carbonate.

As far as dry hopping goes, I'd say wait for fermentation to kick off then place the hops, when most air/O2 has been purged. The magnet trick works fine. Try to use a food grade silicone encased magnet or vacuum seal one yourself if you have a food vacuum sealer available. I think NEIPA brewers consider it standard practice now

What I do currently - for lagers - is let the yeast build up pressure naturally after pitching. Set the spunding to about 15psi and just monitor the pressure over the first day or two, to make sure the keg's sealed. No problems with leaks so far. Touch wood. My ales get fermented open then sealed up towards the end of fermentation, to naturally carbonate.

As far as dry hopping goes, I'd say wait for fermentation to kick off then place the hops, when most air/O2 has been purged. The magnet trick works fine. Try to use a food grade silicone encased magnet or vacuum seal one yourself if you have a food vacuum sealer available. I think NEIPA brewers consider it standard practice now

Mac_rancher

Active Member

- Joined

- Apr 25, 2021

- Messages

- 28

- Reaction score

- 14

Thanks for the info. I'll give my idea a shot and see how it goes. I know NPT is designed to withstand pressure so I feel pretty confident in getting a good seal between the threaded post and the thermowell.

As far as ales go then, how much headspace do you allow for your ales when primary fermenting in a corny keg before applying pressure? I know London Ale III yeast can have a lot of krausen. Also, could you enlighten me on how you set up a blowoff tube on a keg? I know it's a bit off topic from the OP but I appreciate the help.

As far as ales go then, how much headspace do you allow for your ales when primary fermenting in a corny keg before applying pressure? I know London Ale III yeast can have a lot of krausen. Also, could you enlighten me on how you set up a blowoff tube on a keg? I know it's a bit off topic from the OP but I appreciate the help.

deadwolfbones

Well-Known Member

You'd be surprised. I've run Verdant under 25 PSI with only 0.5 gal of headspace and had no issues.I only ferment lagers in corny kegs. I use top-cropping ale yeast so not really compatible with fermenting in corny kegs.

Similar threads

- Replies

- 417

- Views

- 8K