BitterSweetBrews

Tim Trabold

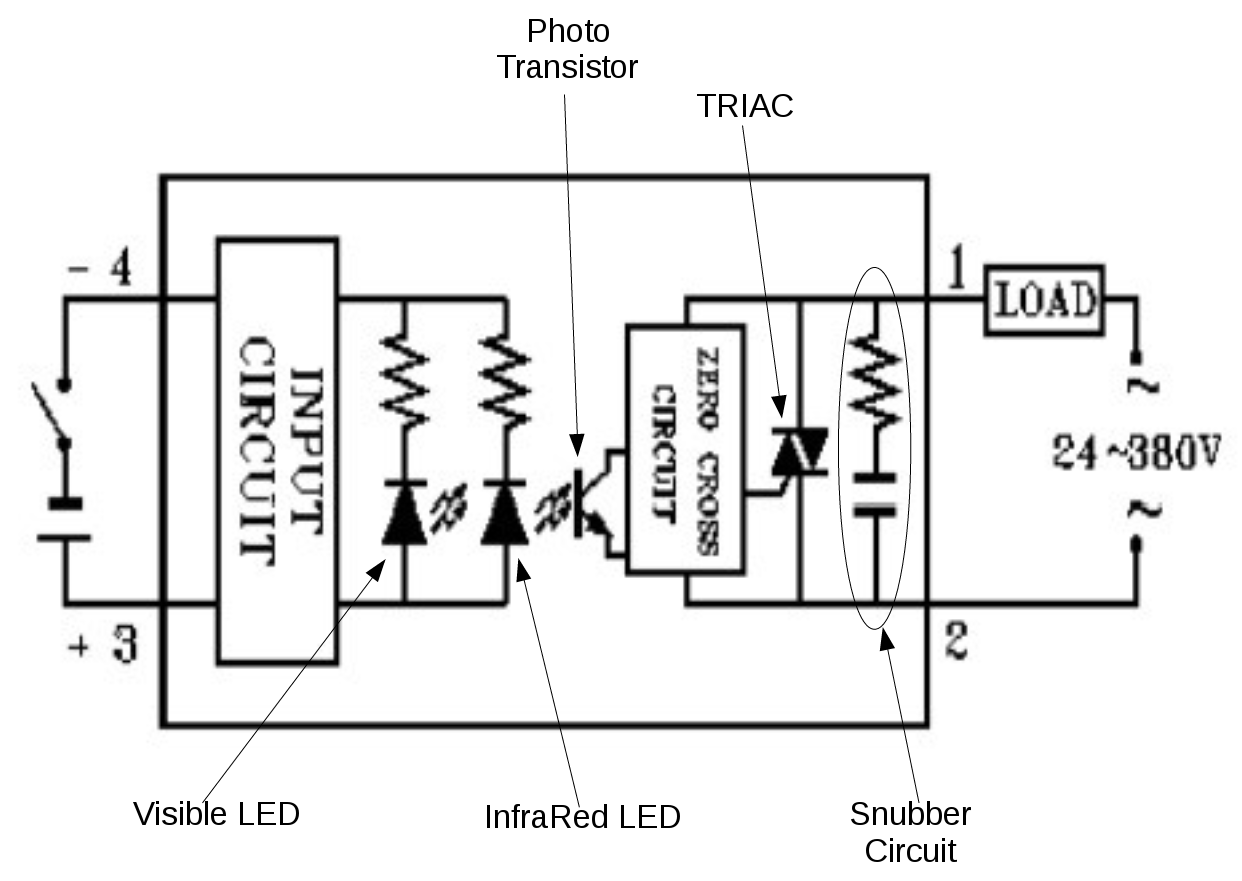

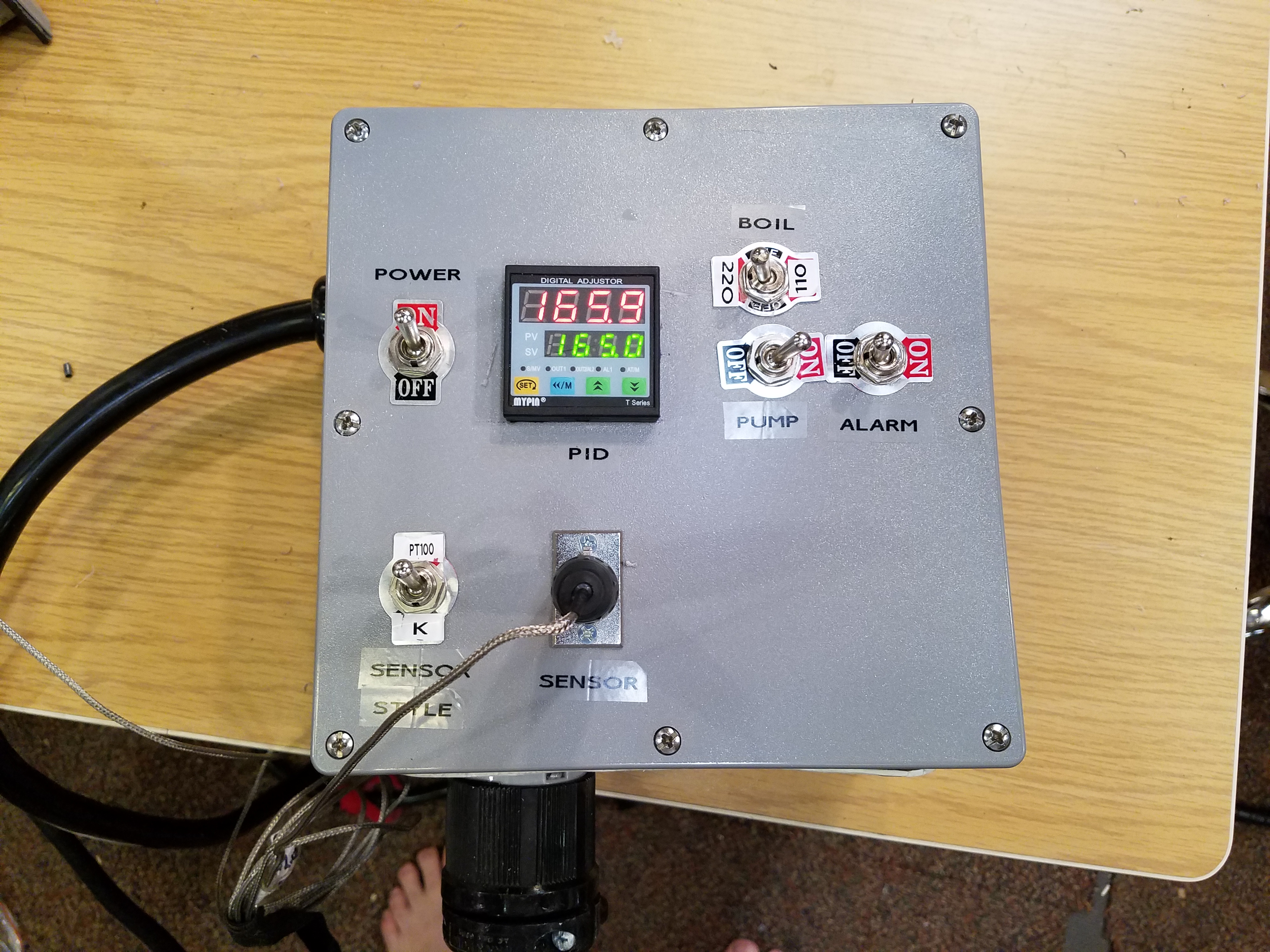

I am having a weird problem. I am building a third brew controller (220 Volt) The issue is that the element is not turning off or cycling, even though the SSR light blinks. The temp in the kettle just keeps rising.

The PID is a MyPIN TD4-SNR and it is wired to a 40 amp Fotec SSR. I am sure they are wired properly. This is my third controller. I am sure I know what to do and have gone back to one of my other controllers for reference.

The 40 amp, Fotec SSR has control wiring from the PID to the 3-24 volt DC terminals. On the AC side of the SSR I have the source on the #1 terminal and the load on the #2 terminal. The other wire to the outlet is direct from the other hot source.

No matter what I set the PID to, using either temp control or manual control, it is running the element at full bore and just cruises by the temp I have set. i.e. If I set the temp to 90 degrees Fahrenheit it just passes 90 and would go all the way to boiling. I had 70 degree water and set the temp to 50 and it just kept heating.

The light on the SSR turns on and off with the PID cycling, but checking voltage it is still passing 100% - 220 V. I have tried three different SSRs and they all act the same. I am afraid that something is blowing the SSRs but can't for the life of me figure out what. I can't find any shorts in the wiring and would think my GFCI would blow if there were any.

I have tried to run the controller's autotune and it never stops.

Does anyone have any advice? I have spent hours on this.

The PID is a MyPIN TD4-SNR and it is wired to a 40 amp Fotec SSR. I am sure they are wired properly. This is my third controller. I am sure I know what to do and have gone back to one of my other controllers for reference.

The 40 amp, Fotec SSR has control wiring from the PID to the 3-24 volt DC terminals. On the AC side of the SSR I have the source on the #1 terminal and the load on the #2 terminal. The other wire to the outlet is direct from the other hot source.

No matter what I set the PID to, using either temp control or manual control, it is running the element at full bore and just cruises by the temp I have set. i.e. If I set the temp to 90 degrees Fahrenheit it just passes 90 and would go all the way to boiling. I had 70 degree water and set the temp to 50 and it just kept heating.

The light on the SSR turns on and off with the PID cycling, but checking voltage it is still passing 100% - 220 V. I have tried three different SSRs and they all act the same. I am afraid that something is blowing the SSRs but can't for the life of me figure out what. I can't find any shorts in the wiring and would think my GFCI would blow if there were any.

I have tried to run the controller's autotune and it never stops.

Does anyone have any advice? I have spent hours on this.

![20180504_073040[1].jpg 20180504_073040[1].jpg](https://cdn.homebrewtalk.com/data/attach/509/509198-20180504-073040-1-.jpg)

![20180504_073044[1].jpg 20180504_073044[1].jpg](https://cdn.homebrewtalk.com/data/attach/509/509199-20180504-073044-1-.jpg)

![20180504_073050[1].jpg 20180504_073050[1].jpg](https://cdn.homebrewtalk.com/data/attach/509/509200-20180504-073050-1-.jpg)