Hey all, I have been hanging out for a while asking a few questions here and there but mostly learning. Well I recently decided to pull the trigger on my build. I have found it very difficult to find the time to drag all of my equipment up from the basement to the garage for an all grain brew day.

I was totaling 7 hours on average with setup, cleaning and tear down. I just don't have that kind of time anymore with a 2 year old and another on the way so I'm going electric!

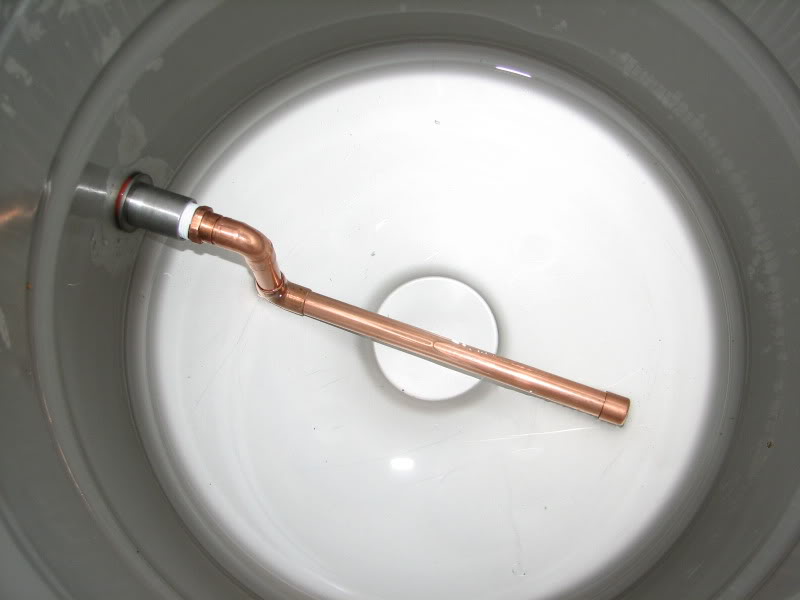

My thought is that everything will be set up and ready to go in my large unfinished basement with a large sink next to it. I will be going eHERMS with PID's so I can walk away from it at certain times in the brew if I have to.

Here is the cool part that I am excited about (I still have not decided weather I enjoy engineering brewing equipment, or actually brewing beer more) I will be making everything in this system!

I will be using keggles, and a P-J diagram that I like. Another element will be budget, so I will be coming up with parts wherever I can find them cheaply. Some things I may splurge on because I really want them or because I'm just lazy sometimes.

I have already started on my stand that I am building out of steel salvaged from an old broken harbor freight trailer. I thought some may be interested to see this because it will be heavily DIY and on a budget... Let's see how well I can do! Thanks everyone for inspiration.

Sent from my Nexus 7 using Home Brew mobile app

I was totaling 7 hours on average with setup, cleaning and tear down. I just don't have that kind of time anymore with a 2 year old and another on the way so I'm going electric!

My thought is that everything will be set up and ready to go in my large unfinished basement with a large sink next to it. I will be going eHERMS with PID's so I can walk away from it at certain times in the brew if I have to.

Here is the cool part that I am excited about (I still have not decided weather I enjoy engineering brewing equipment, or actually brewing beer more) I will be making everything in this system!

I will be using keggles, and a P-J diagram that I like. Another element will be budget, so I will be coming up with parts wherever I can find them cheaply. Some things I may splurge on because I really want them or because I'm just lazy sometimes.

I have already started on my stand that I am building out of steel salvaged from an old broken harbor freight trailer. I thought some may be interested to see this because it will be heavily DIY and on a budget... Let's see how well I can do! Thanks everyone for inspiration.

Sent from my Nexus 7 using Home Brew mobile app