This is my first time kegging, so it's probably just lack of understanding or just being a bit paranoid.

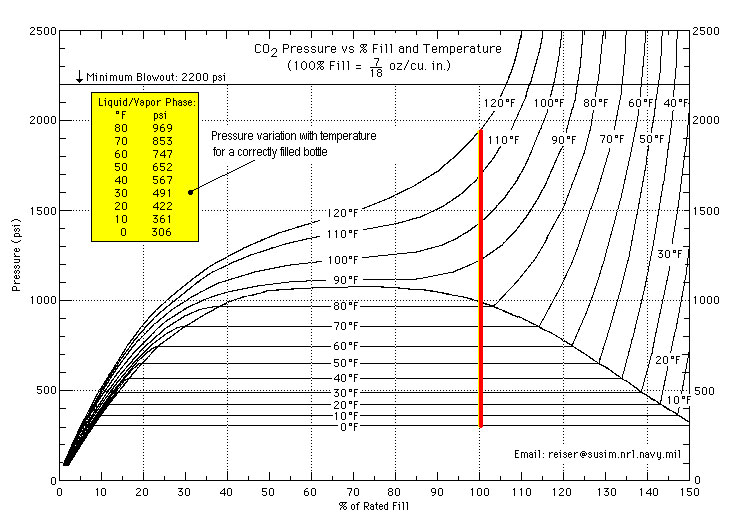

I kegged about 3 gallons of beer and it's been sitting in the kegerator at around 13 psi for about 2 weeks. The 20lb CO2 tank sits outside the fridge, in about 65-68F ambient temperature. The high pressure gage was originally reading at 800 psi, but I just noticed today that it's now reading a little under 500 psi. I haven't checked the pressure too many times recently, but if I recall it read close to 800 psi a few days ago. CO2 usage consisted of a few oxygen purges, a few times that I disconnected the gages and everything (from not knowing what I was doing), and pouring a few pints. Checked for leaks at all connections by spraying starsan, nothing.

I know this gage is generally classified as "useless", but is this normal? It's probably fine, but I just don't want to find the gage in the red zone and be outta gas. I've read that a 20lb tank should last for dozens of kegs. I can put the tank on a scale (which is a pain since it's not a continuous reading) but being that there doesn't look like any leak, not sure how that would help.

I kegged about 3 gallons of beer and it's been sitting in the kegerator at around 13 psi for about 2 weeks. The 20lb CO2 tank sits outside the fridge, in about 65-68F ambient temperature. The high pressure gage was originally reading at 800 psi, but I just noticed today that it's now reading a little under 500 psi. I haven't checked the pressure too many times recently, but if I recall it read close to 800 psi a few days ago. CO2 usage consisted of a few oxygen purges, a few times that I disconnected the gages and everything (from not knowing what I was doing), and pouring a few pints. Checked for leaks at all connections by spraying starsan, nothing.

I know this gage is generally classified as "useless", but is this normal? It's probably fine, but I just don't want to find the gage in the red zone and be outta gas. I've read that a 20lb tank should last for dozens of kegs. I can put the tank on a scale (which is a pain since it's not a continuous reading) but being that there doesn't look like any leak, not sure how that would help.