HoundboundCo

Member

Here’s a question to something I have not been able to find an answer too. Two questions actually.

Questions:

1: I did not have any success on my first attempt at a closed transfer and I’m assuming it’s because the was no vent from the gas post. I only had the liquid out line connect from fermenter to keg and upon the beer flowing from the fermenter it just came to a complete stop upon reaching the disconnect and did not enter the keg at all. Will simply running a gas line from the gas post into a bucket of Starsan fix my issue while doing the transfer?

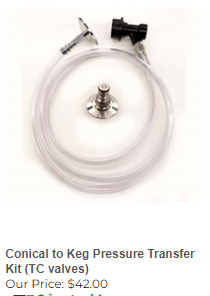

2: my issue is finding the right attachment for my disconnect to connect to a 1/2 tube that runs from my spike flex. I’m trying to skate around spending money on the pressure transfer package spike makes.

Questions:

1: I did not have any success on my first attempt at a closed transfer and I’m assuming it’s because the was no vent from the gas post. I only had the liquid out line connect from fermenter to keg and upon the beer flowing from the fermenter it just came to a complete stop upon reaching the disconnect and did not enter the keg at all. Will simply running a gas line from the gas post into a bucket of Starsan fix my issue while doing the transfer?

2: my issue is finding the right attachment for my disconnect to connect to a 1/2 tube that runs from my spike flex. I’m trying to skate around spending money on the pressure transfer package spike makes.