Brewnation

Well-Known Member

- Joined

- Sep 28, 2015

- Messages

- 68

- Reaction score

- 3

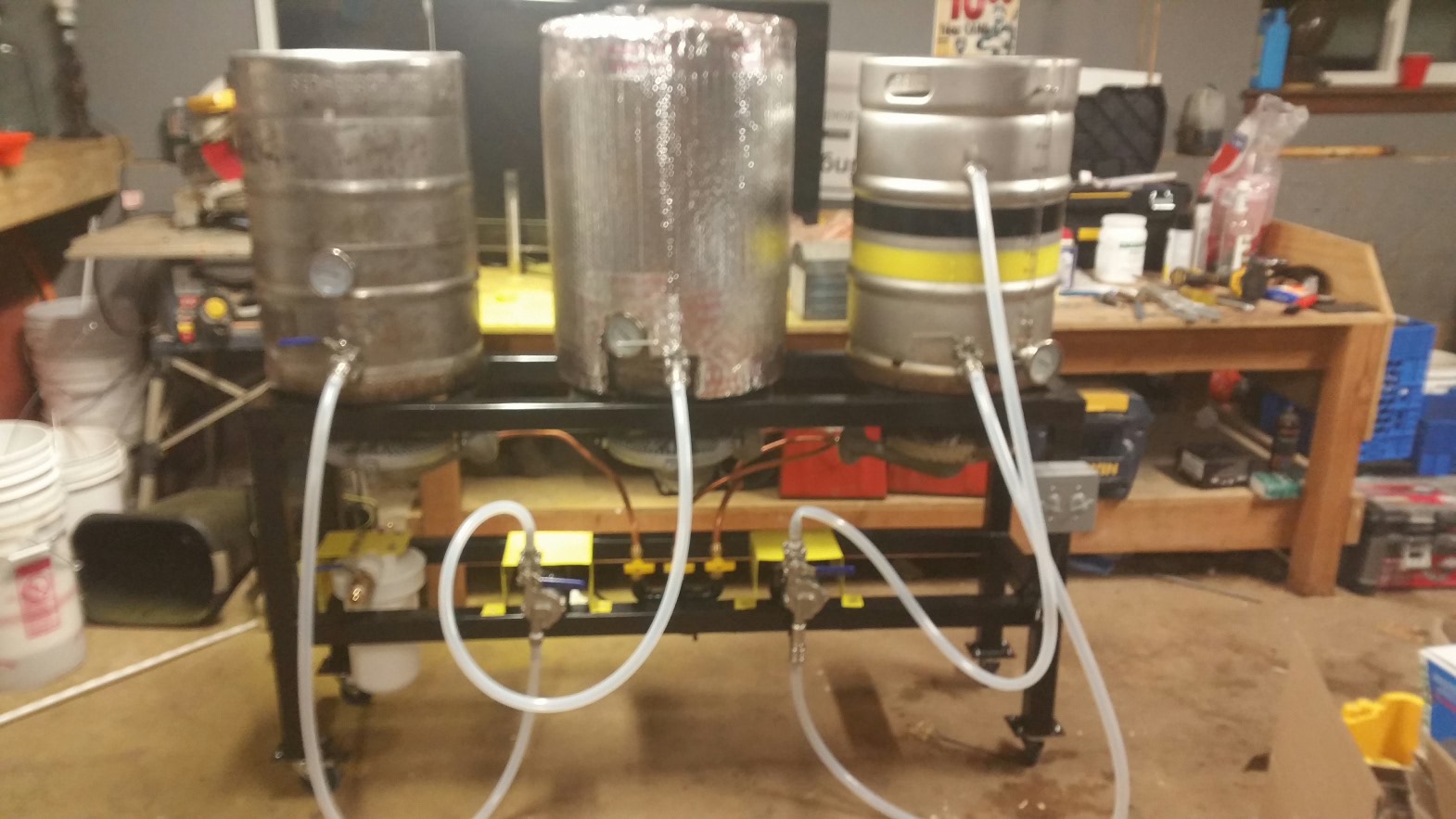

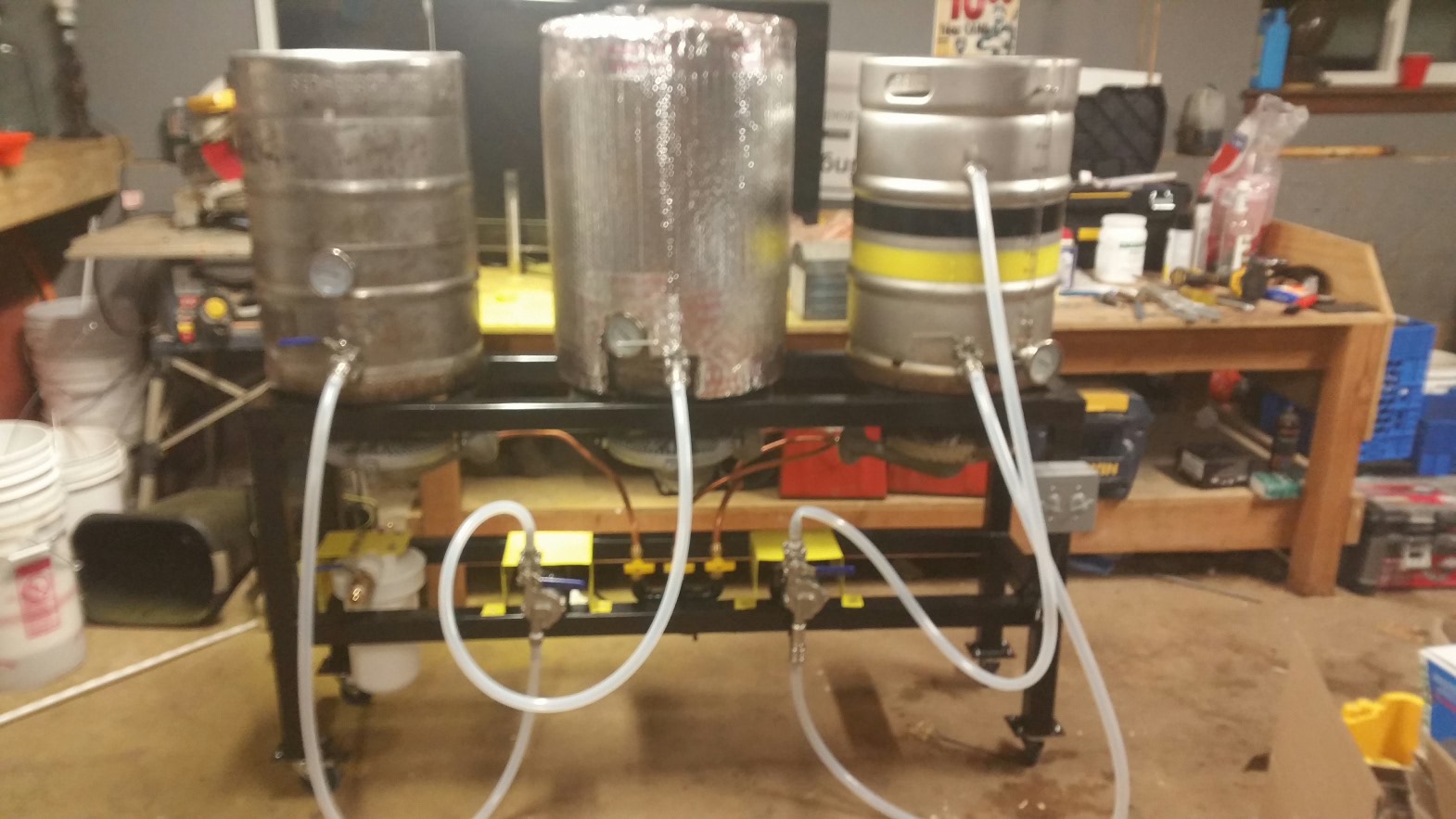

I have two chugger pumps set up on my brewstand with 3/4od an 1/2id silicone hose. Is there a trick getting these things to prime? When I open the valve on keg I'm having trouble getting liquid to flow out. I have to open and close the valve on pump and move hose around. Also when I have them going with valves mostly closed for fly sparging they seem to lose there prime and I need to open them up once in awhile to keep flow. I'm wondering if maybe my hoses are too long or if 3/8id would be better.