What are generally considered good (or best) ways to get a good pour with minimum waste, assuming the faucets are about 10 feet from the keezer (from basement to main floor, mostly vertical)?

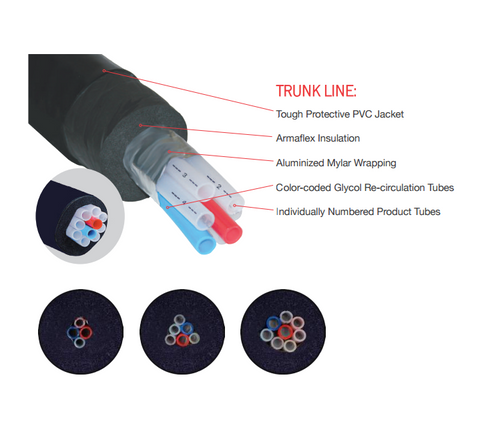

I was thinking of recirculating water (or a solution of) through an insulated pipe along with the draft lines, from keezer to faucet. Potentially even with an additional loop going outside during winter-time, to cut energy costs. I saw such ideas floated about in other threads, but not sure if people actually do that, and if those who do regret it or not.

I've got 6 kegs lying around that I'd like to make the most of.

I was thinking of recirculating water (or a solution of) through an insulated pipe along with the draft lines, from keezer to faucet. Potentially even with an additional loop going outside during winter-time, to cut energy costs. I saw such ideas floated about in other threads, but not sure if people actually do that, and if those who do regret it or not.

I've got 6 kegs lying around that I'd like to make the most of.