nostalgia

Well-Known Member

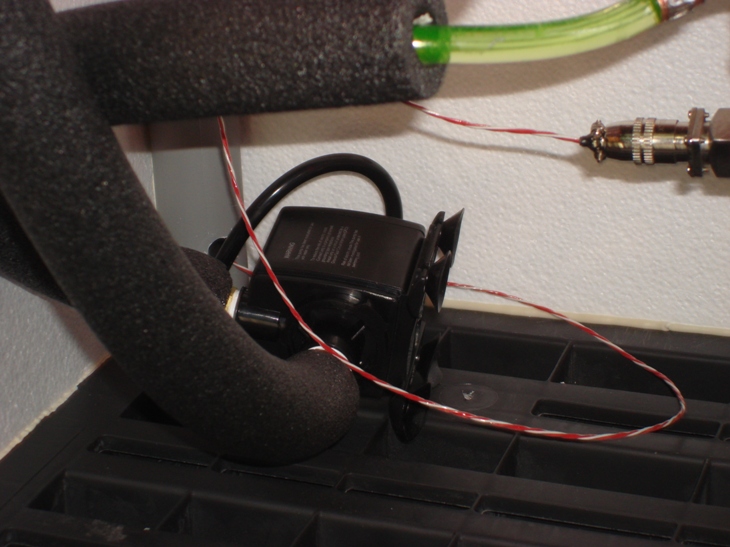

When I get my conical fermenters, I'm planning to temperature control them by running coolant through a stainless steel coil in the beer. I had been working on converting an air conditioner to a glycol chiller, but have been looking around at other options.

One that looks promising is an aquarium chiller. This little 1/13 HP job claims it's good for tanks up to 50 gallons for $350. It can be set from 39 to 82F, which would even be good for lagers.

I guess the only issue would be if I wanted to use it for two brews at different temps, since I assume it checks the temperature of the inbound coolant instead of the temp in the fermenter.

Anyone ever try something like this, or see any other off-the-shelf chillers that might work?

Thanks,

-Joe

One that looks promising is an aquarium chiller. This little 1/13 HP job claims it's good for tanks up to 50 gallons for $350. It can be set from 39 to 82F, which would even be good for lagers.

I guess the only issue would be if I wanted to use it for two brews at different temps, since I assume it checks the temperature of the inbound coolant instead of the temp in the fermenter.

Anyone ever try something like this, or see any other off-the-shelf chillers that might work?

Thanks,

-Joe