MatthewTCranford

Active Member

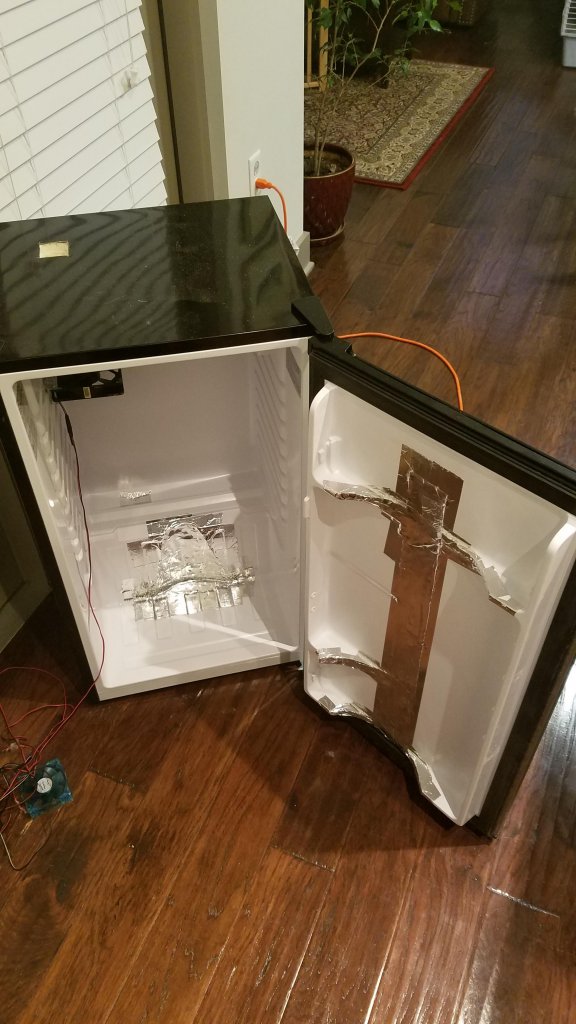

So, I built this guy in college and have had it for about 8 years. Time for a revamp and some upgrades. Would be open to any constructive ideas, guidance, and help!

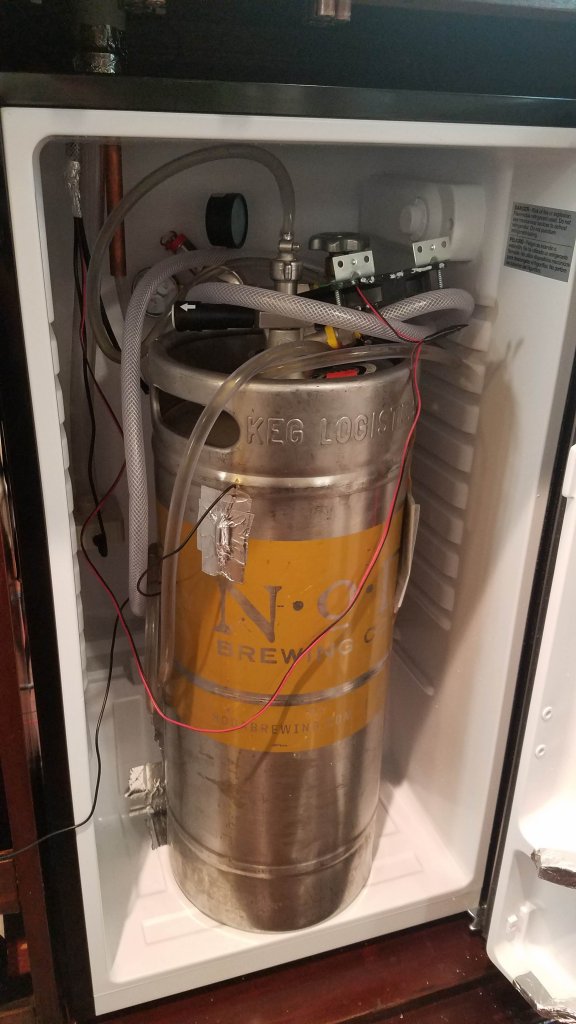

Features: Housed in a mini-fridge cabinet found at a warehouse selling old hotel furniture. Constructed an Irish Coffin tower. Built some wine racks in. Added another layer of molding at the top to lay in beer caps with glass on top. Back features a spot to put the CO2 canister. Beer and CO2 lines run into the fridge through the top.

Was pretty happy with it for a first build, but time for an upgrade.

Current planned upgrades Include:

-New Mini-fridge

-Relay bottle caps, Finish with hard clear epoxy

-New Tower: (http://rover.ebay.com/rover/1/711-5...0001&campid=5338413729&icep_item=362422635017)

-Looking to turn the shiny brass into brushed brass

-Upgrade the shelf to pull out to allow for better access

-Add in an Inkbird ITC-1000 for better and easier temp control

-Add in tower and fridge fans to assist with temp control

-Touch up damaged wood and refinish where needed

Features: Housed in a mini-fridge cabinet found at a warehouse selling old hotel furniture. Constructed an Irish Coffin tower. Built some wine racks in. Added another layer of molding at the top to lay in beer caps with glass on top. Back features a spot to put the CO2 canister. Beer and CO2 lines run into the fridge through the top.

Was pretty happy with it for a first build, but time for an upgrade.

Current planned upgrades Include:

-New Mini-fridge

-Relay bottle caps, Finish with hard clear epoxy

-New Tower: (http://rover.ebay.com/rover/1/711-5...0001&campid=5338413729&icep_item=362422635017)

-Looking to turn the shiny brass into brushed brass

-Upgrade the shelf to pull out to allow for better access

-Add in an Inkbird ITC-1000 for better and easier temp control

-Add in tower and fridge fans to assist with temp control

-Touch up damaged wood and refinish where needed

Last edited: