Hi all

I'm in a little bit of a pickle. Yesterday was brew day and the first time I did 5 gallons (as opposed to 2.5). I thought my fermentation bucket was 5.5 gallons but its actually literally exactly 5.05, so when I poured the wort and pitched the yeast, the level was almost flush with the top. Since it was like 2am and I had done all this work, I just said "f&&#ck it" and let it ride.

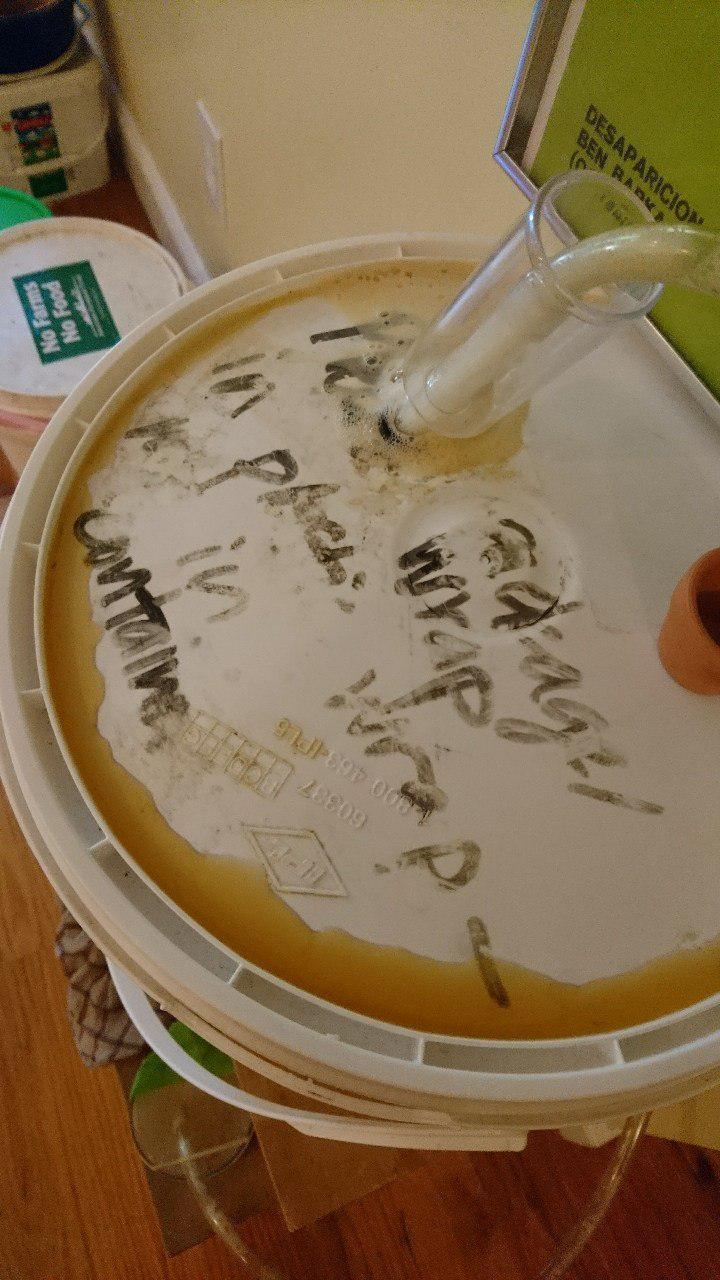

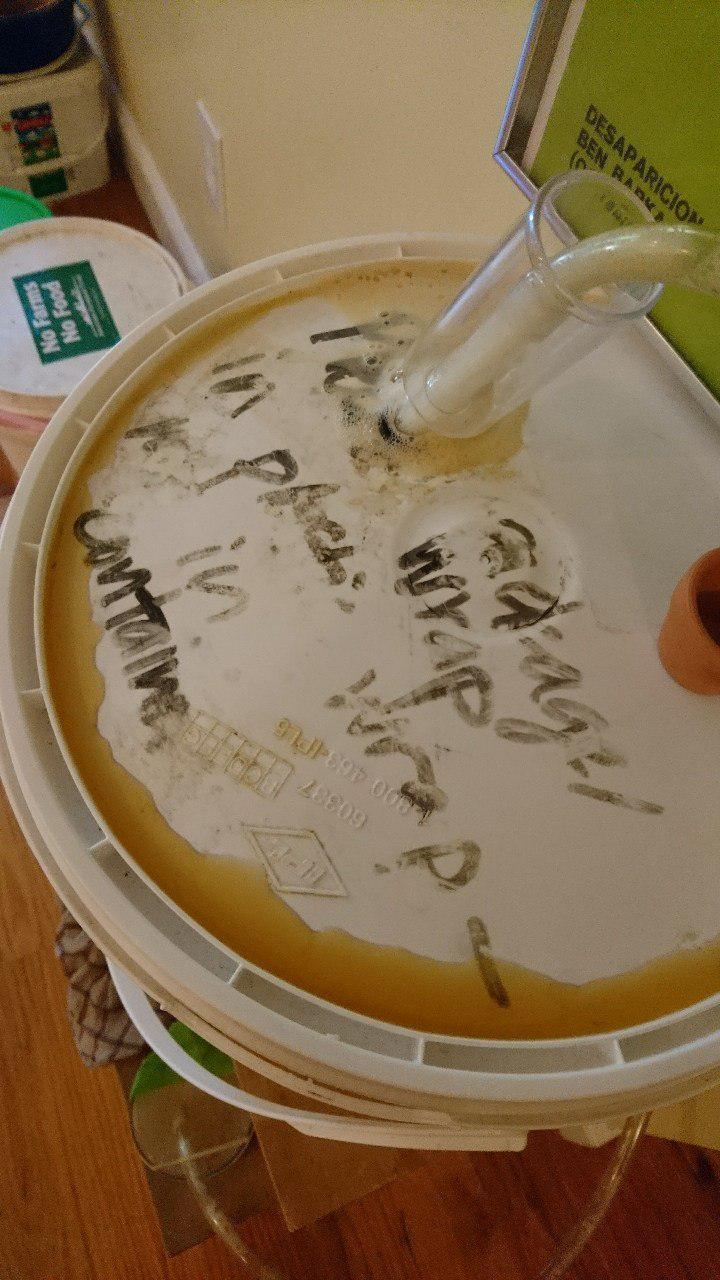

Now its been 12 hours and fermentation is happening nicely, but some actual liquid is escaping through the top around the fermentation lock (CO2 is also nicely bubbling through the lock as well).

I was thinking of running out and getting a 5.5 or 6 gallon so there's more airspace above the wort and so more of it doesn't literally leak out as a result of fermentation. Is there any downside to just pouring it from one to another? Should I just leave this batch and if I do, will it get too contaminated or will I lose too much beer if I do? Thanks for any guidance!

I'm in a little bit of a pickle. Yesterday was brew day and the first time I did 5 gallons (as opposed to 2.5). I thought my fermentation bucket was 5.5 gallons but its actually literally exactly 5.05, so when I poured the wort and pitched the yeast, the level was almost flush with the top. Since it was like 2am and I had done all this work, I just said "f&&#ck it" and let it ride.

Now its been 12 hours and fermentation is happening nicely, but some actual liquid is escaping through the top around the fermentation lock (CO2 is also nicely bubbling through the lock as well).

I was thinking of running out and getting a 5.5 or 6 gallon so there's more airspace above the wort and so more of it doesn't literally leak out as a result of fermentation. Is there any downside to just pouring it from one to another? Should I just leave this batch and if I do, will it get too contaminated or will I lose too much beer if I do? Thanks for any guidance!