262andbrew

Well-Known Member

Background (and all of my experience) I got 4 old hand me down Coke kegs that had no valves in the lids. Replaced a couple of o-rings on posts and one lid o-ring and everything was good. I had to ramp up pressure on one of them for the lid to seat, but really everything was pretty easy.

I just doubled the size of my flock, adding 4 more pinlocks, but these lids are different. I tested the pressure when they arrived and everything was good.

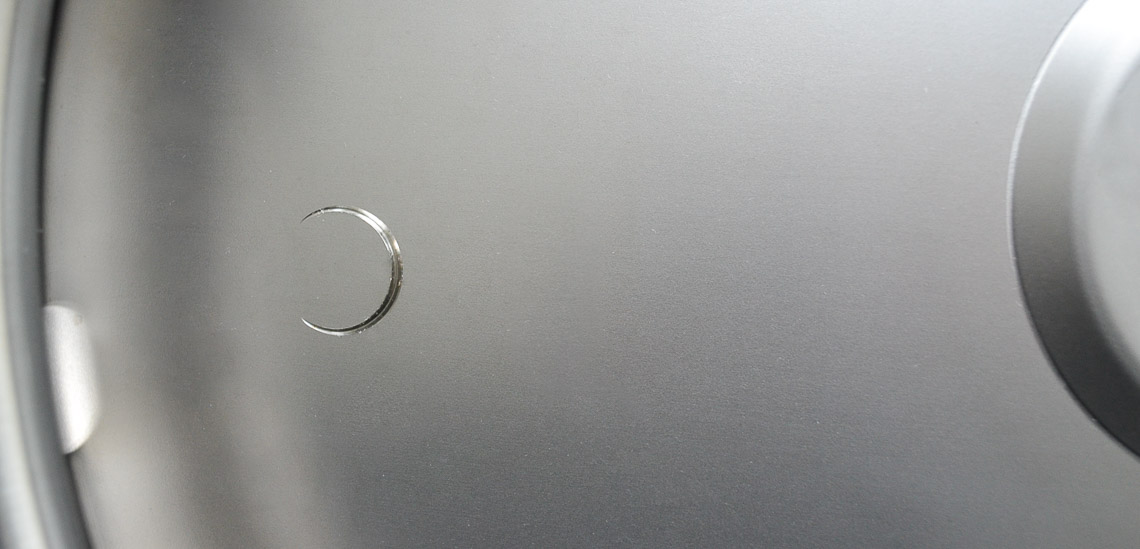

I gave 2 of them a good cleaning, and sterilized in preparation for kegging 2 new batches tonight. I put pressure to them fussed with the lid o-rings, but eventually got that figured out BUT, and this is my the reason for my question, the pressure relieve valves in the lids are leaking at any more than just a few pounds of pressure. That is going to be a problem.

I tried the Keg lube, no dice.

I removed and cleaned, no dice.

I swapped valves from lid to lid, no dice.

I grabbed another one and cleaned up one of my old ones so I got my brews kegged, but I need to figure out my new problem children.

So, what do I do now?

Can I disable the valves?

Do I just need to buy new springythings? (it looks like the are 12 bucks a piece...not going to break me, but kind of sucks)

Why did they work when they showed up and not work when wet? Can they not get wet?

Let me know what you would do next for these problem lids. I am spent, what I thought was going to be a 2 hour clean->transfer->cleanup night end up being 4 hours of frustration and wasted co2. Good thing I had a few on tap and I have a forgiving wife .

.

Peace.

I just doubled the size of my flock, adding 4 more pinlocks, but these lids are different. I tested the pressure when they arrived and everything was good.

I gave 2 of them a good cleaning, and sterilized in preparation for kegging 2 new batches tonight. I put pressure to them fussed with the lid o-rings, but eventually got that figured out BUT, and this is my the reason for my question, the pressure relieve valves in the lids are leaking at any more than just a few pounds of pressure. That is going to be a problem.

I tried the Keg lube, no dice.

I removed and cleaned, no dice.

I swapped valves from lid to lid, no dice.

I grabbed another one and cleaned up one of my old ones so I got my brews kegged, but I need to figure out my new problem children.

So, what do I do now?

Can I disable the valves?

Do I just need to buy new springythings? (it looks like the are 12 bucks a piece...not going to break me, but kind of sucks)

Why did they work when they showed up and not work when wet? Can they not get wet?

Let me know what you would do next for these problem lids. I am spent, what I thought was going to be a 2 hour clean->transfer->cleanup night end up being 4 hours of frustration and wasted co2. Good thing I had a few on tap and I have a forgiving wife

Peace.