vsanchez949

Well-Known Member

So, I've finally decided to pull the trigger and build a stand after 4 years of brewing. I hadn't had a real stand before, just used a banjo burner and folding tables/milk crates or whatever I could get to transfer liquids.

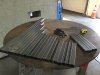

The stand I'm building is small and compact because all of my kids power wheels, bikes and what not take up all of my precious space in the garage. I copied the design from gbrewing.com.

Since I work for a machine/weld/electrical shop I have all kinds of goodies at my disposal. I was able to pick up some 16ga. 1.5" x 1.5" square tubing for really cheap. As soon as I get some extra cash I will be adding pumps, for now I'll use gravity as best as I can to transfer my liquids, I'm only brewing 5 gallon batches so far with a 7 gallon pot and a 10 gallon Rubbermaid mash tun with false bottom.

I'm gonna start cutting up my pieces today and hopefully get it welded together by the end of the week. Let me know what you guys think! Thanks!! 😄

Sent from my iPhone using Home Brew

The stand I'm building is small and compact because all of my kids power wheels, bikes and what not take up all of my precious space in the garage. I copied the design from gbrewing.com.

Since I work for a machine/weld/electrical shop I have all kinds of goodies at my disposal. I was able to pick up some 16ga. 1.5" x 1.5" square tubing for really cheap. As soon as I get some extra cash I will be adding pumps, for now I'll use gravity as best as I can to transfer my liquids, I'm only brewing 5 gallon batches so far with a 7 gallon pot and a 10 gallon Rubbermaid mash tun with false bottom.

I'm gonna start cutting up my pieces today and hopefully get it welded together by the end of the week. Let me know what you guys think! Thanks!! 😄

Sent from my iPhone using Home Brew