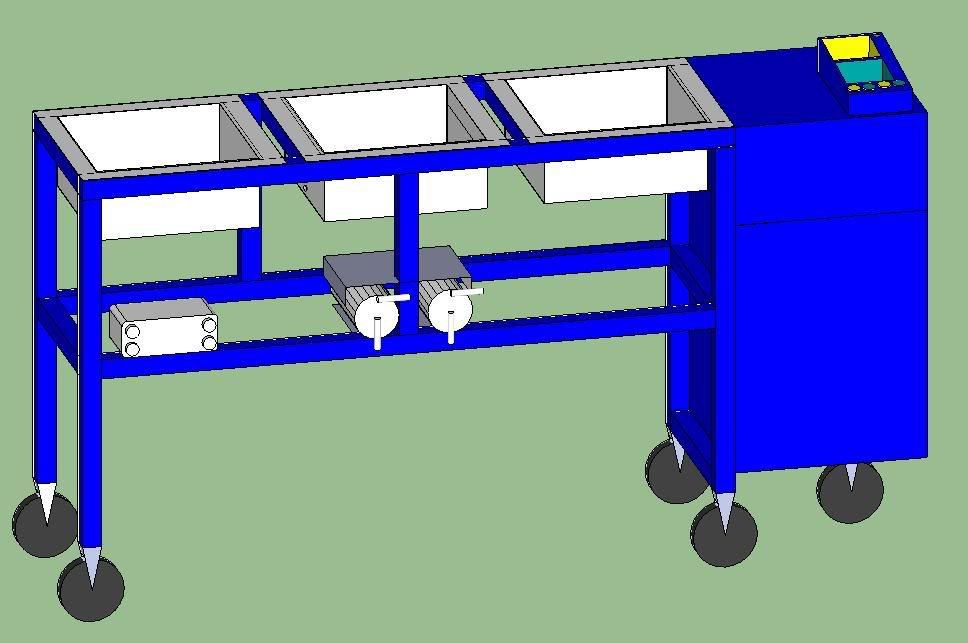

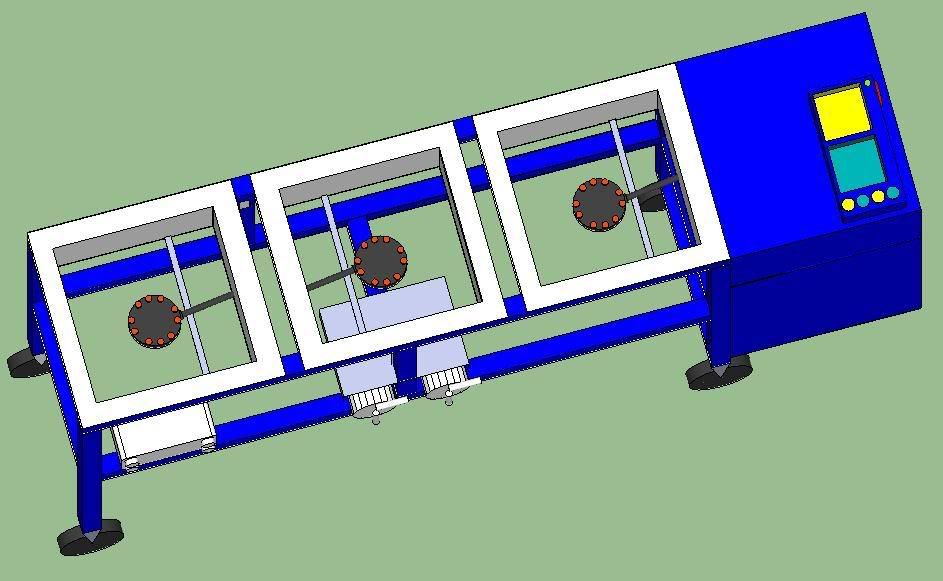

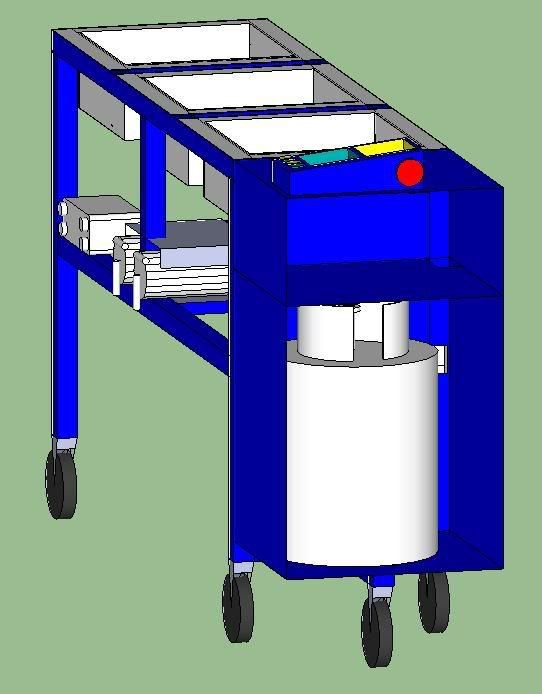

I'm sketching up my brutus 10ish plans. I have seen build threads where they used 1.5x1.5 inch square tubing and i have also seen threads where they used .065 pipe wall tubing.

Does anyone have arguments against 1.5" tubing or using .065 or .083 wall thickness. I want a safe sturdy stand but .120 seems heavy.

Does anyone have arguments against 1.5" tubing or using .065 or .083 wall thickness. I want a safe sturdy stand but .120 seems heavy.